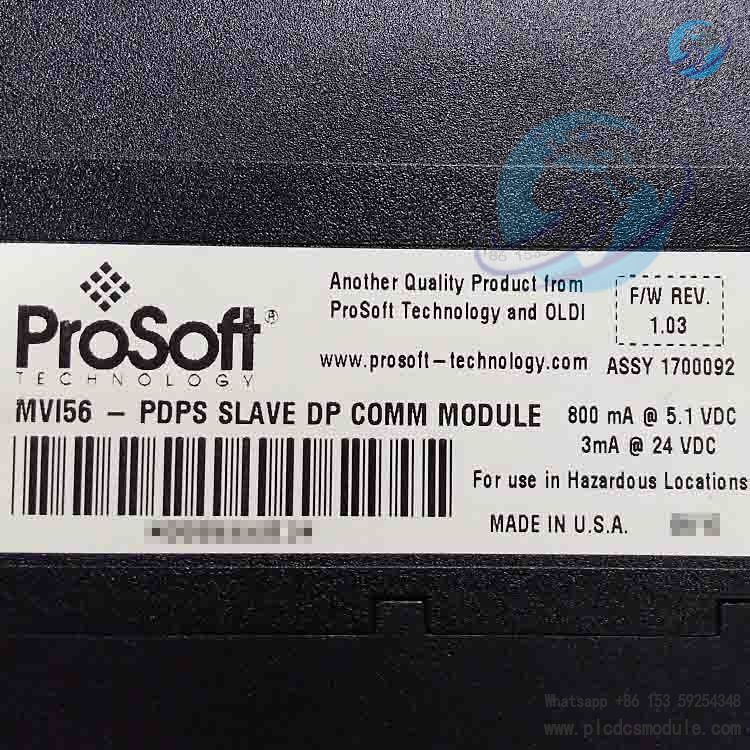

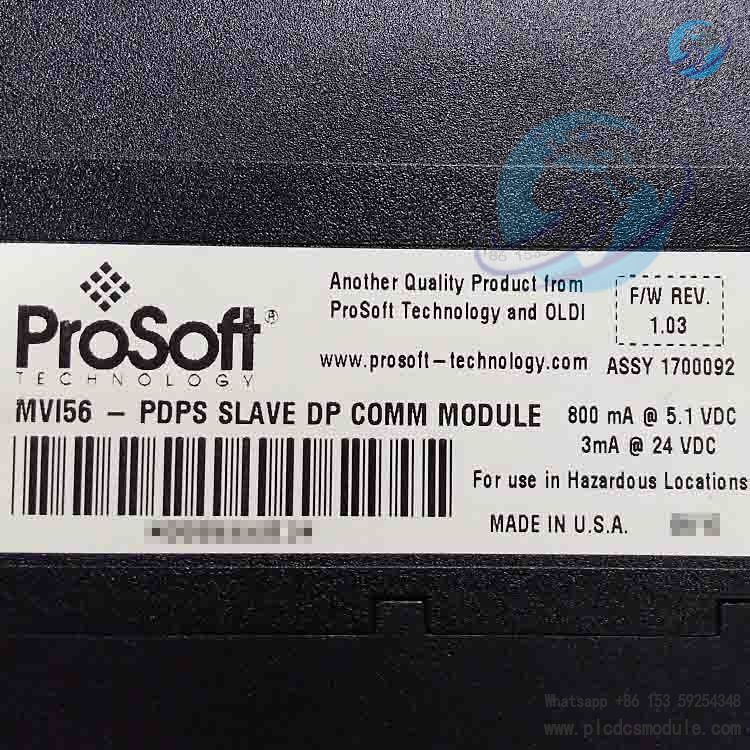

1. Product Overview

The ProSoft MVI56-PDPS is a PROFIBUS DP slave communication module specifically designed for Rockwell Automation ControlLogix I/O-compatible processors, intended to solve the problem of communication and interconnection between different devices in industrial scenarios and enable convenient interfacing between ControlLogix processors and PROFIBUS DP master devices. With the continuous expansion of the PROFIBUS DP protocol's application in the industrial market, this module, by virtue of its stable performance and flexible configuration, is widely used in numerous critical industrial fields including power distribution, petrochemicals, water and gas treatment, SCADA and DCS, providing reliable support for industrial data transmission and the coordinated control of equipment.

Download

Core Functions and Advantages

Powerful Protocol Support and Data Transmission Capability: The module is equipped with a PROFIBUS DP slave protocol driver and supports the implementation of PROFIBUS V0 slave, enabling the establishment of a high-efficiency data transmission channel between the module and Rockwell Automation ControlLogix processors. Users can customize the data mapping and DP port operations according to actual requirements, which not only simplifies the operation process but also ensures the flexibility and efficiency of data transmission, meeting the demand for real-time data interaction in industrial scenarios.

Convenient Configuration and Debugging Functions: The module is provided with a configuration/debug serial port that can be directly connected to a computer for module configuration, status monitoring and fault troubleshooting. A serial cable is included with the product upon delivery, eliminating the need for additional accessory procurement. After users complete configuration editing on the computer, the configuration file can be downloaded and stored in the MVI56 module. The entire process features simple operation, which greatly reduces debugging difficulty and saves time costs.

Sufficient Data Storage and Flexible Mapping: The module supports access to the input and output images of the device, with the maximum input and output data reaching 244 bytes respectively and the total data volume up to 400 bytes. These input and output data blocks can be mapped and set by users in the data memory of the inRAx module, which not only provides ample space for data storage but also enables flexible data transmission in conjunction with other protocols, further enhancing the adaptability of the module in complex industrial networks.

General Specifications

Compatibility and Installation

The module features a single-slot design, compatible with the 1756 backplane, and can be installed in local or remote racks, enabling flexible adaptation to different industrial control cabinet layouts and meeting diverse installation requirements. Meanwhile, it eliminates the need for large-scale adjustments to the existing ControlLogix system architecture, reducing the difficulty of system upgrading and retrofitting.

Data Interaction Method

Identified as an input/output module, it can access the processor memory to realize data transmission between the processor and the module. Data transmission is accomplished via Ladder Logic, and sample ladder files are included with the product for users to quickly configure the module with ease. The module's configuration data is derived from the configuration text files downloaded to it, and sample configuration files are also provided as a reference for users, simplifying the configuration process.

Environmental Adaptability

In terms of operating temperature, the module can run stably in an environment of 0 to 60°C (32 to 140°F), with a storage temperature range extended to -40 to 85°C (-40 to 185°F), adapting to different temperature conditions at industrial sites. It achieves an operational shock resistance rating of 30g and a relative humidity tolerance range of 5% to 95% (non-condensing), maintaining stable performance in industrial environments with certain vibration and humidity changes to ensure the long-term reliable operation of the equipment.

Status Indication

The module is equipped with multiple LED indicators, including a module status indicator, a backplane transmission status indicator, an application status indicator, as well as serial activity and error LED indicators. Users can intuitively check the module's operating status through the indicator lights, promptly detect and troubleshoot issues such as module faults and abnormal data transmission, improving the efficiency of equipment maintenance.

3005319639

3005319639