Multi-protocol parallel operation: Supports the simultaneous execution of three modes – Profibus DP Master, DP Slave and FDL (Layer 2 Protocol). It enables communication tasks for different roles without mode switching, adapts to various scenarios in complex industrial networks such as master-slave device interaction and direct inter-device communication, and enhances the flexibility of network topology.

Full baud rate compatibility: Covers all standard Profibus baud rates ranging from 9.6 Kbaud to 12 Mbaud. Users can select the appropriate baud rate according to actual communication distance and data volume requirements. It not only meets the needs of high-speed short-distance data transmission (e.g., 12 Mbaud for communication among dense devices in short distances), but also adapts to stable low-speed long-distance transmission (e.g., 9.6 Kbaud for connecting scattered peripherals over long distances).

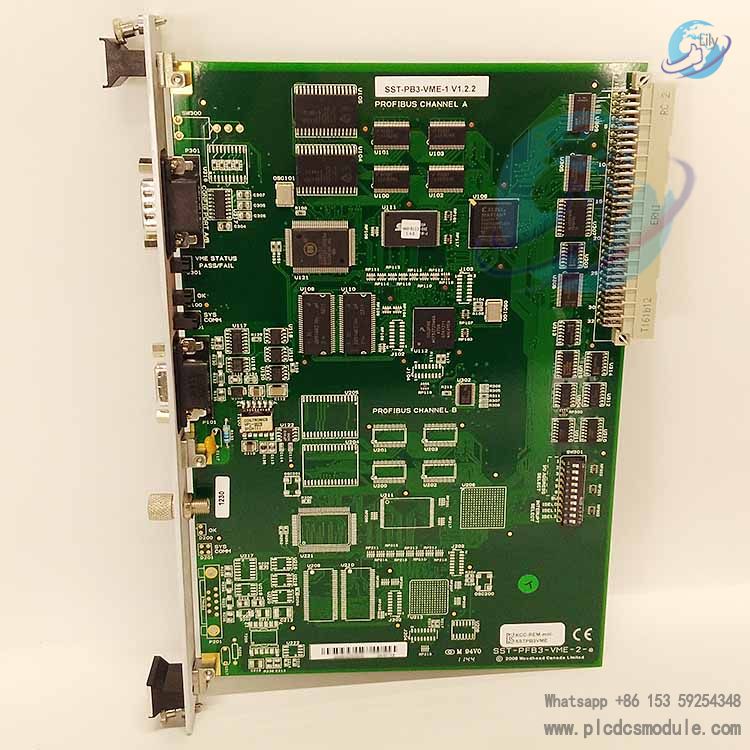

VME bus adaptation: Optimized for the characteristics of the VME bus, it supports 16-bit data transmission (VME D16) under two address transmission modes: VME A24 (standard address) and A16 (short I/O address). It can be seamlessly integrated into the VMEbus hardware architecture and achieve high-efficiency data interaction with VME-based devices without additional adaptive hardware.

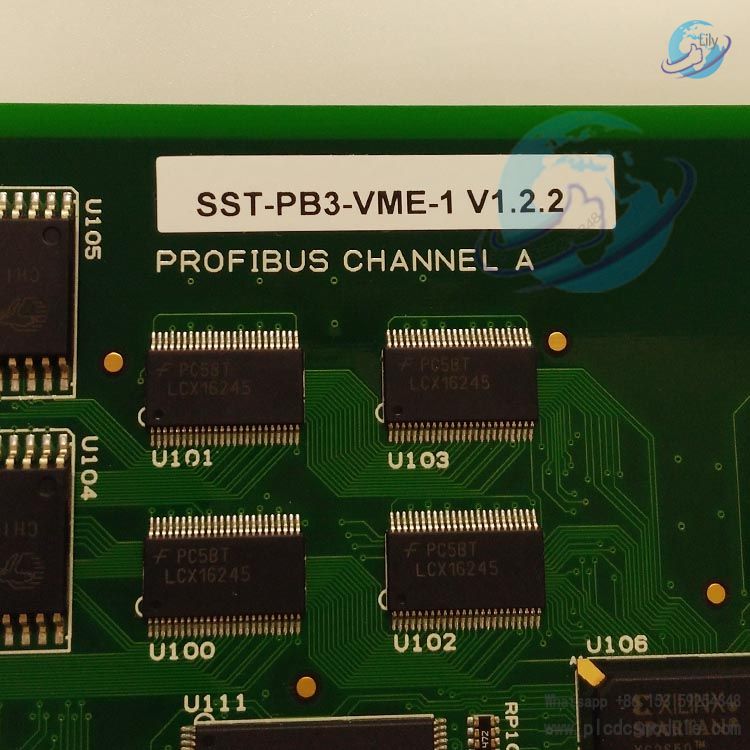

Two versions available: The network card is offered in two versions – single-port (for access to 1 independent Profibus network) and dual-port (for access to 2 independent Profibus networks). Users can make a selection based on the network scale of industrial sites. The dual-port version is particularly suitable for scenarios that require isolating communication between different device groups or implementing network redundancy, which improves system reliability.

Visual diagnosis: Equipped with three types of diagnostic LED indicators for system status, watchdog timeout and communication status. Maintenance personnel can quickly determine the device operation status (e.g., normal/interrupted communication, whether the watchdog protection is triggered by the system, etc.) through the color or flashing status of the indicators, which shortens fault troubleshooting time and reduces maintenance costs.

Software & Hardware Support and Tools

Standard Software Package: Includes DP configuration software for offline configuration, which enables pre-completion of network parameter and device node configuration; provides custom driver development software to support users in developing exclusive drivers for target operating systems; comes with sample codes and Microsoft Windows 32-bit kernel drivers, among which the sample programs for the DOS environment also include C language source codes. It serves as a development reference for developers, streamlines the software integration process and shortens the development cycle.

Optional Configuration Tool: PROFIBUS Console, an optional Windows 32-bit application, supports offline debugging of Profibus DP-V0 networks. It features an intuitive Drag & Drop user interface and can directly call the PROFIBUS GSD files provided by field device manufacturers for device addition and parameter configuration. After configuration is completed, all configuration files can be downloaded to the SST Profibus VMEbus card via a serial port, ensuring easy operation and a lower rate of configuration errors.

Hardware Interface Design: Enables data interaction with the host processor through shared dual-port memory without relying on external libraries, which streamlines the development of custom drivers across different operating systems. It also provides a fully documented host memory interface, allowing developers to clearly understand memory mapping and data interaction logic and reducing development difficulty.

Network and Hardware Specifications

Network Specifications

Protocol Support: Covers Profibus DP-V0 Class 1 Master, Profibus DP-V0 Class 2 Master, Profibus DP-V0 Slave and FDL Layer 2 Protocol, meeting the communication requirements of different functional roles.

Data Rate: Supports a maximum of 12 Mbps and is compatible with the full range of standard Profibus rates, adapting to different transmission distances and real-time performance requirements.

Cable Requirements: Belden 3079A cable or Brad Harrison 85-0001 PVR2 shielded twisted pair (UL certified) is recommended to ensure signal transmission stability and reduce the impact of electromagnetic interference on communication.

Connector Type: Each port/channel is equipped with a DB9 female connector and is also compatible with the Brad Harrison diagnostic D-Sub connector (Model MA9D01-42) for convenient connection and diagnosis.

Isolation Protection: Features 1000 V isolation capability, which effectively resists interference such as voltage fluctuations and surges in industrial sites, protects the safety of equipment and networks, and improves communication stability.

Hardware Specifications

Bus Compatibility: Complies with the VME Spec VME54 standard (compatible with Vita 1.1 1997 version) for seamless integration into VMEbus systems.

Processor: Equipped with a ColdFIRE 5272 processor with strong data processing capability to ensure the efficient execution of communication tasks.

Memory Configuration: Occupies a minimum 256K window in the host memory map, with a 256K×16-bit memory window allocated to each port/channel, enabling flexible deployment in the standard VME space. For I/O resources, each port/channel occupies a 32-byte range and is located on a 1K boundary set by DIP switches, facilitating address allocation and management.

Interrupt Control: Supports selection of IRQ Level 1 to 7 interrupts or interrupt disable via DIP switches. Users can configure flexibly according to system interrupt resources and real-time performance requirements to avoid interrupt conflicts.

Physical Dimensions: Adopts a double-height (6U) module design that complies with industrial standard dimensions and is suitable for installation in standard VME racks.

Power Supply and Power Consumption: Only 5V voltage supply is required, with an allowable voltage fluctuation of ±5% to adapt to the power supply environment of industrial sites. The typical current consumption is 800 mA for the single-port version and 1400 mA for the dual-port version, featuring rational power consumption control to reduce the power supply burden of the system.

Environmental Adaptability: The operating temperature range is 0ºC (32ºF) to +60ºC (140ºF), the storage temperature range is -40ºC (-40ºF) to +85ºC (185ºF), and the humidity tolerance range is 5% to 90% (non-condensing). It can adapt to harsh industrial site environments such as high and low temperature changes and humidity fluctuations to ensure stable equipment operation.

Related Products

3005319639

3005319639