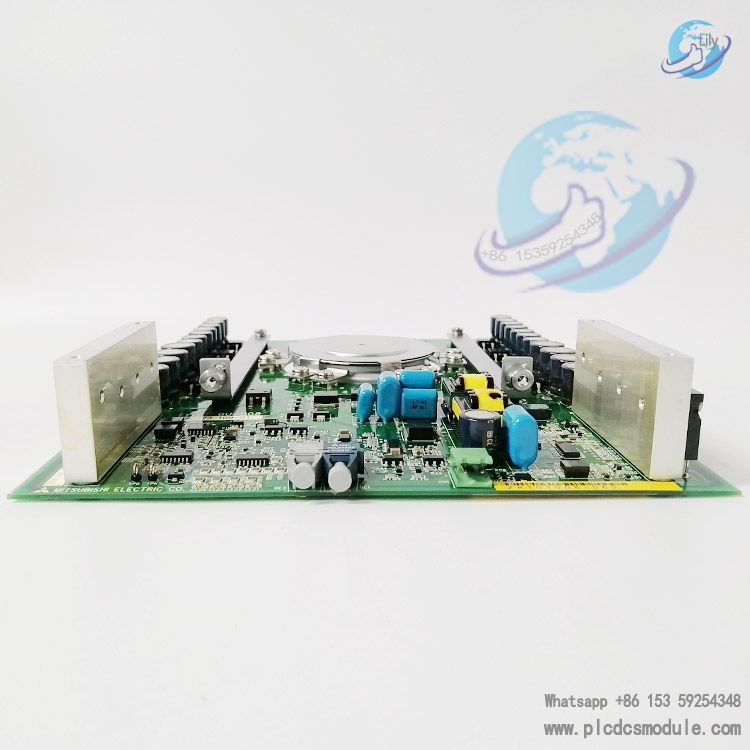

Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. Co-launched by Allen-Bradley and Mitsubishi Electric, the Mitsubishi 81001-450-53-R (8100145053R) Triple IGCT Module is a core power semiconductor device engineered for medium-voltage and high-power industrial applications. Adopting a three-unit integrated package design and integrating the advanced power electronics technologies of the two enterprises, it features low conduction loss, high switching performance and superior reliability. It delivers efficient and stable power conversion and control solutions for medium and high-voltage frequency converters, industrial motor drives and various high-power power conversion equipment, and serves as an ideal alternative to traditional devices such as silicon-controlled rectifiers (SCR) for enhancing system power density and operational efficiency.

Core Technical Features

Core Advantages of IGCT Technology

This module adopts IGCT technology, combining the characteristics of high blocking voltage and high current density of thyristors with the advantage of high switching speed of transistors. It achieves low conduction loss under medium-voltage operating conditions, greatly improving the energy utilization efficiency of the system and reducing operational energy consumption.

Compared with traditional power devices, its optimized gate drive circuit design enables faster and controllable switching processes, which effectively reduces switching loss. It is suitable for frequent switching requirements under intermediate frequency (<1kHz) operating conditions and ensures the stable operation of equipment.

Triple Integrated Package Design

Featuring a triple integrated package, the module integrates three IGCT chips into a single module. This design not only saves electrical cabinet installation space and simplifies circuit wiring, but also reduces connection losses and parasitic parameters between devices, enhancing the power density and operational reliability of the overall system.

The packaging process offers excellent electrical insulation performance and heat dissipation capacity, meeting the requirements of electrical isolation and thermal management in complex industrial operating conditions and extending the service life of the module.

Key Performance Parameters

- Rated Voltage: 3300V, meeting the voltage grade requirements of medium-voltage industrial systems and adapting to common medium-voltage motor drive and power conversion scenarios.

- Rated Current: 500A, with a strong current-carrying capacity to drive the stable operation of high-power industrial loads.

- Switching Frequency: <1kHz, suitable for power conversion needs under intermediate frequency operating conditions, balancing switching performance and loss control.

- Operating Temperature: -40℃ to +150℃, the wide temperature range design allows it to adapt to temperature fluctuations in different industrial environments and improve application flexibility.

- Cooling Method: Water cooling supported, the high-efficiency heat dissipation design ensures the thermal stability of the module under high-load operating conditions and avoids performance degradation or damage caused by overheating.

High Reliability and Compatibility

Utilizing high-quality semiconductor materials and precision manufacturing processes, and undergoing rigorous industrial condition testing, the module has excellent surge and anti-interference capabilities. It can cope with complex electromagnetic environments and voltage/current fluctuations in industrial sites, reducing the risk of equipment failure.

It is highly compatible with medium-voltage frequency converters and industrial control systems of Allen-Bradley, Mitsubishi and other mainstream brands, and can be conveniently integrated into existing equipment or new system designs, lowering the cost of engineering applications.

Product Functions

Power Conversion and Control

As a core power switching device, it enables efficient conversion and precise control of medium-voltage electrical energy, providing a stable variable-frequency drive power supply for medium-voltage motors. By adjusting the output voltage and frequency, it meets the motor's speed and torque requirements under different operating conditions and improves motor operational efficiency.

Fast Switching and Fault Protection

It features fast switching response capability and can quickly switch working states according to the instructions of the control system. Meanwhile, the module is built-in with multiple protection mechanisms such as overcurrent, overvoltage and overheating protection. When abnormal operating conditions are detected, it can cut off the circuit in a timely manner to protect the safety of the module itself and the downstream equipment.

Energy Loss Optimization

The low conduction loss characteristic reduces energy waste during electrical energy conversion and lowers equipment operational energy consumption, complying with the development requirements of energy conservation and emission reduction in the industrial field. It also reduces heat generation and eases the heat dissipation burden of the system.

Application Scenarios

Industrial Motor Drives

Widely applied in the medium and high-voltage motor drive systems of large fans, water pumps, compressors and other equipment in industries such as iron and steel, metallurgy and mining. It provides efficient and reliable power control for the equipment and improves production efficiency.

Medium-Voltage Frequency Converters

Serving as the core power module of medium-voltage frequency converters, it is adapted to the design and manufacturing of high-power frequency converters, meets the variable-frequency speed regulation requirements of various industrial loads, optimizes production processes and reduces equipment maintenance costs.

Power Quality Improvement Equipment

Usable in power quality improvement equipment such as Static Var Compensators (SVC) and Active Power Filters (APF). It improves the voltage and current waveforms of the power grid and enhances the operational stability and power quality of the power grid.

New Energy and Power Transmission

Adapted to new energy power generation equipment such as photovoltaic inverters and wind power converters, as well as power transmission fields including High-Voltage Direct Current (HVDC) transmission and Flexible Alternating Current Transmission Systems (FACTS), facilitating the grid connection of new energy and the efficient transmission of electrical energy.

Installation and Maintenance Key Points

- Strictly comply with electrical specifications during installation to ensure reliable connection between the module, heat dissipation system and drive circuit, avoiding heating or malfunctions caused by poor contact.

- Regularly inspect the module's heat dissipation condition, electrical connection status and protection functions, and timely clean dust on the surface of heat dissipation components to ensure heat dissipation efficiency.

- Select original genuine products when replacing the module to avoid impacting system operation due to compatibility issues or quality defects; meanwhile, conduct installation and commissioning in strict accordance with the operation manual to ensure the full exertion of the module's performance.

3005319639

3005319639