ABB DSQC658 (3HAC025779-001) is a single-channel DeviceNet master/slave communication module exclusively designed for ABB robot control systems, and is mainly compatible with controller series such as IRC5. Its core function is to enable high-speed data interaction between robots and devices including PLCs, sensors and actuators in the DeviceNet network. It also supports both master and slave operating modes, allowing flexible integration into various industrial automation network architectures, and serves as a key interface component for the interconnection between robot systems and external DeviceNet devices. Its replacement model is 3HAC037084-001ABB. With a compact industrial-grade design and stable communication performance, this module is widely applied in robot control scenarios across automotive manufacturing, mechanical processing, logistics and warehousing and other fields, helping to improve the integration efficiency and control precision of systems.

ABB DSQC658 (3HAC025779-001) is a single-channel DeviceNet master/slave communication module exclusively designed for ABB robot control systems, and is mainly compatible with controller series such as IRC5. Its core function is to enable high-speed data interaction between robots and devices including PLCs, sensors and actuators in the DeviceNet network. It also supports both master and slave operating modes, allowing flexible integration into various industrial automation network architectures, and serves as a key interface component for the interconnection between robot systems and external DeviceNet devices. Its replacement model is 3HAC037084-001ABB. With a compact industrial-grade design and stable communication performance, this module is widely applied in robot control scenarios across automotive manufacturing, mechanical processing, logistics and warehousing and other fields, helping to improve the integration efficiency and control precision of systems.

Download

Technical Specifications

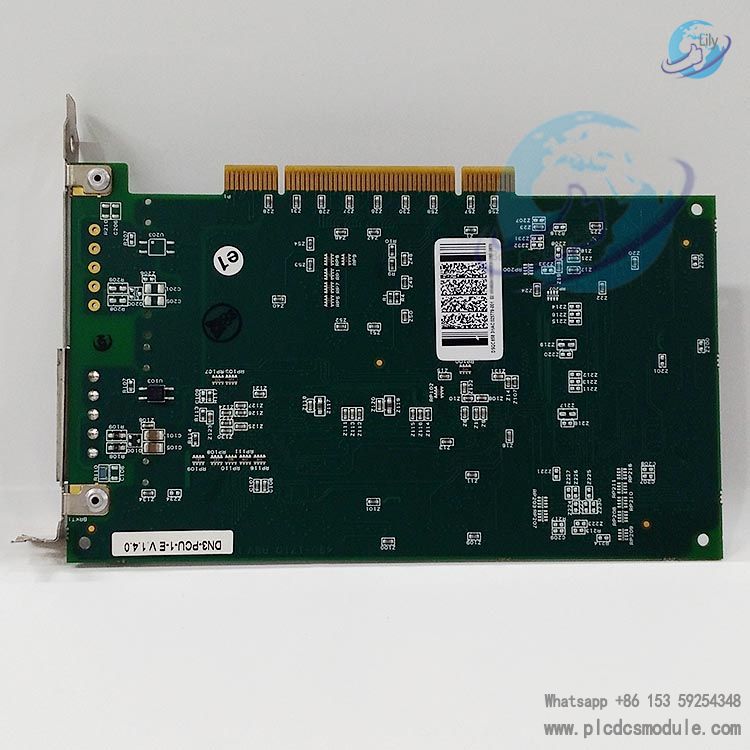

Model: DSQC658 (3HAC025779-001), Replacement Model: 3HAC037084-001ABB

Communication Protocol: DeviceNet

Operating Mode: Dual mode: Master / Slave

Number of Interfaces: 1 DeviceNet interface

Dimensions: 118×45×28mm

Weight: 0.142kg

Protection Class: IP20

Operating Voltage: 24V DC

Operating Temperature: -20℃ ~ +60℃

Core Features & Functions

Dual-mode Communication Capability: Supports flexible switching between DeviceNet Master and Slave modes. In Master mode, it can manage multiple slave devices in the network to realize centralized control and data acquisition; in Slave mode, the robot controller can access the DeviceNet network of upper-level PLCs or other master devices, adapting to different system topology requirements and meeting the needs of multi-device coordinated control scenarios.

High-efficiency Single-port Connection: Equipped with 1 DeviceNet interface that supports the standard DeviceNet communication protocol, ensuring real-time and reliable data transmission to meet the real-time control demands of industrial sites. The interface design complies with industrial specifications, facilitating on-site wiring and connection.

Visual Status & Easy Maintenance: Integrated with LED status indicators that intuitively display the module's working status (power supply, communication, faults, etc.), helping engineers quickly locate network connection issues, shorten fault troubleshooting time and reduce system maintenance costs.

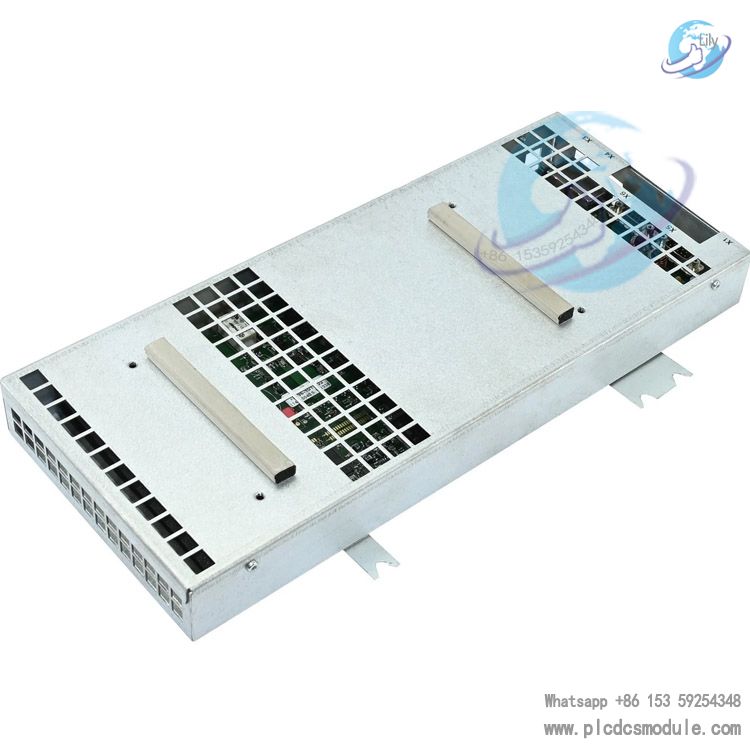

Industrial-grade Stable Design: With an IP20 protection rating, it is suitable for complex industrial site environments with dust and electromagnetic interference; the operating temperature range is -20℃ to +60℃, enabling stable operation under harsh working conditions and ensuring long-term reliable communication connections.

Compact Size & Easy Installation: Measuring 118×45×28mm with a net weight of 0.142kg, it features a compact modular design and can be easily installed inside the robot control cabinet, saving installation space and adapting to the dense layout in the cabinet. The simple installation method allows for rapid deployment.

Software Configuration and Integration

Controller & Software Compatibility: Mainly compatible with ABB IRC5 series robot controllers, configurable via RobotStudio software. It enables convenient completion of network parameter setting, node address assignment, communication data mapping and other operations, and supports system pre-defined networks and internal slave devices to simplify the initialization configuration process.

Address Configuration: A unique DeviceNet node address (range 0-63) must be assigned to the module, which can be completed via hardware DIP switches or software settings. This ensures normal communication in the network and avoids communication anomalies caused by address conflicts.

Data Interaction Capability: Supports high-efficiency digital signal transmission and control command interaction, enabling real-time data sharing between the robot and external devices (e.g., robot operation status feedback, action command delivery for external devices), which ensures the coordinated control precision of the system.

Application Scenarios

Robot and PLC Coordinated Control: In production lines such as automotive welding and electronic assembly, the module enables the robot controller to establish DeviceNet communication with the PLC, realizing PLC's motion control and task scheduling of the robot, as well as the feedback of position, status and other data from the robot to the PLC, ensuring the efficient and coordinated operation of the production line.

Data Interaction Between Robots and Peripheral Devices: Connect robots with DeviceNet bus-type sensors, pneumatic actuators, conveyor line driving devices, etc., to realize the robot's precise detection of material positions, automatic opening and closing of clamps, synchronous linkage of conveyor lines and other functions, improving the flexibility and intelligence level of automated production lines.

Multi-robot Collaborative System: In multi-robot collaborative scenarios such as handling and palletizing, the module is used as a communication interface to interconnect different robot controllers through the DeviceNet network, realizing task allocation, motion coordination and so on, ensuring the accuracy and safety of multi-robot collaborative operations.

ABB DSQC658 (3HAC025779-001) is a single-channel DeviceNet master/slave communication module exclusively designed for ABB robot control systems, and is mainly compatible with controller series such as IRC5. Its core function is to enable high-speed data interaction between robots and devices including PLCs, sensors and actuators in the DeviceNet network. It also supports both master and slave operating modes, allowing flexible integration into various industrial automation network architectures, and serves as a key interface component for the interconnection between robot systems and external DeviceNet devices. Its replacement model is 3HAC037084-001ABB. With a compact industrial-grade design and stable communication performance, this module is widely applied in robot control scenarios across automotive manufacturing, mechanical processing, logistics and warehousing and other fields, helping to improve the integration efficiency and control precision of systems.

ABB DSQC658 (3HAC025779-001) is a single-channel DeviceNet master/slave communication module exclusively designed for ABB robot control systems, and is mainly compatible with controller series such as IRC5. Its core function is to enable high-speed data interaction between robots and devices including PLCs, sensors and actuators in the DeviceNet network. It also supports both master and slave operating modes, allowing flexible integration into various industrial automation network architectures, and serves as a key interface component for the interconnection between robot systems and external DeviceNet devices. Its replacement model is 3HAC037084-001ABB. With a compact industrial-grade design and stable communication performance, this module is widely applied in robot control scenarios across automotive manufacturing, mechanical processing, logistics and warehousing and other fields, helping to improve the integration efficiency and control precision of systems.

3005319639

3005319639