Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. The ABB

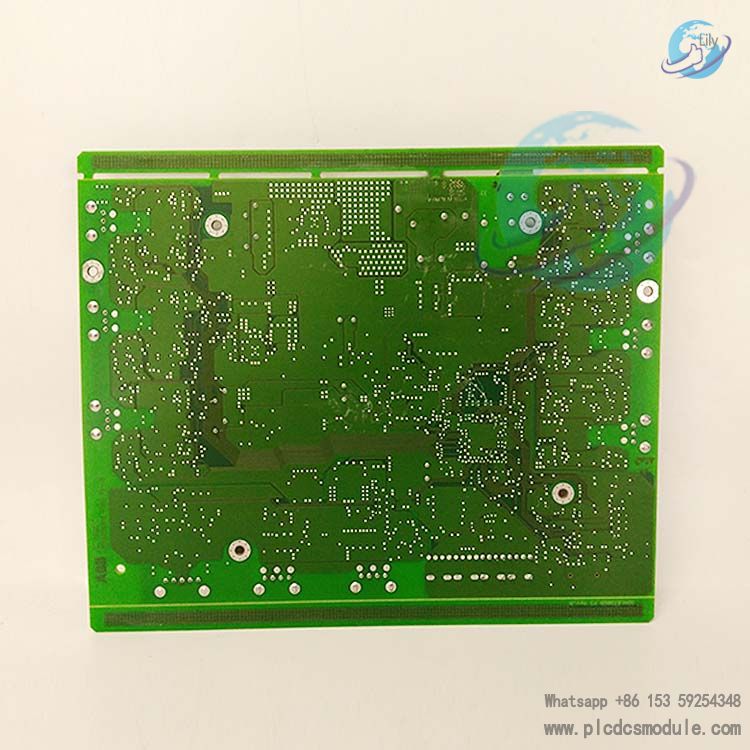

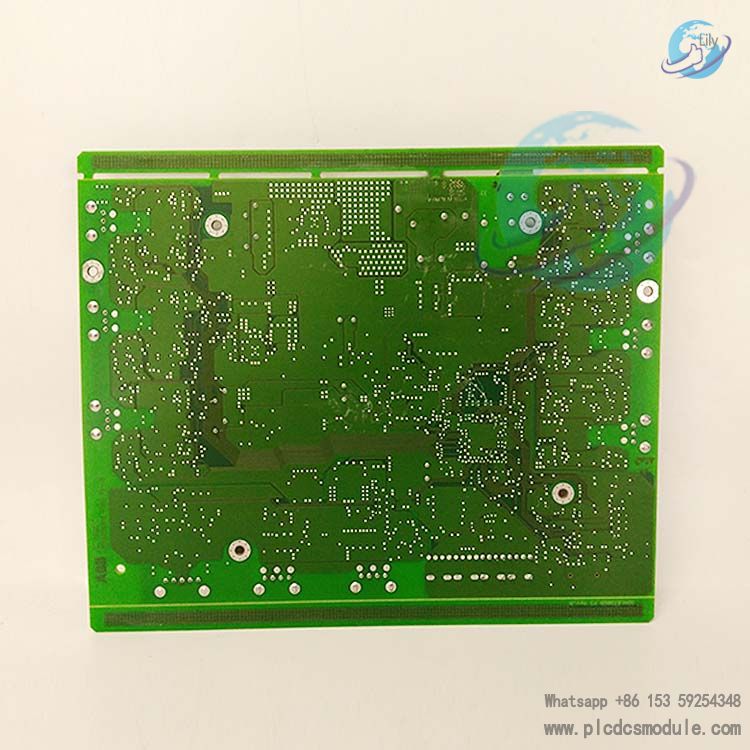

GC C960 C103 3BHE033067R0103 Varnished Printed

Circuit Board (PCB VARNISHED) is a core control component specifically designed for harsh industrial environments characterized by high humidity, heavy dust, and strong corrosion. It is highly compatible with mainstream control systems such as ABB Symphony Plus and AC 800M.

Through professional three-proof (moisture-proof, dust-proof, corrosion-proof) varnish treatment, combined with the selection of industrial-grade components and enhanced circuit design, this circuit board can implement complex control logic operations, multi-type signal interaction, and equipment status monitoring. It provides stable and durable hardware support for heavy industrial equipment in industries including electric power, chemical engineering, and metallurgy.

Its compact layout and standardized interface design ensure direct integration into existing control cabinets without the need for additional adaptation or modification. At the same time, the moisture resistance, salt spray resistance, and mildew resistance capabilities conferred by the varnish layer make it an ideal control component for high-pollution and high-humidity scenarios.

Core Features and Advantages

1. Professional Varnish Protection for Harsh Environments

- Three-proof Varnish Process: Adopts imported polyurethane three-proof varnish with a coating thickness of 25-30μm, certified to IPC-CC-830 Class B, featuring:

- Moisture Resistance: Operates stably for a long time in an environment of 95% RH (40℃, no condensation);

- Corrosion Resistance: Withstands 5% sodium chloride solution salt spray test (per ASTM B117 standard) for ≥48 hours;

- Mildew Resistance: Passes GB/T 2423.16-2008 mildew growth test (Grade 0, no mildew growth).

- Enhanced Anti-contamination Capability: The smooth and low-viscosity surface of the varnish layer reduces the adhesion of dust and oil stains, lowering the risk of circuit short circuits caused by contaminants. It can be cleaned simply by wiping with a dry cloth during maintenance.

- Wide-temperature Stable Operation: Equipped with wide-temperature components (-40℃~+85℃), the varnish layer does not crack or peel off under extreme temperatures, ensuring the circuit board works reliably for a long time in scenarios such as high-temperature workshops and outdoor cabinets.

2. High-performance Control and Signal Processing

- Powerful Computing Core: Equipped with a 32-bit RISC industrial processor with an operation speed of 150 MIPS, supporting complex control algorithms (e.g., PID closed-loop control, logic interlocking). The control cycle can be as low as 5ms, meeting high real-time control requirements.

- Multi-type Signal Compatibility:

- Analog Input (AI): 12 channels, supporting 4-20mA/0-10V DC, with an acquisition accuracy of ±0.1% FS, compatible with sensors for temperature, pressure, flow, etc.;

- Digital Input/Output (DI/DO): 24 channels of DI (response time <1ms), 16 channels of DO (relay output 2A/250V AC), supporting dry contact/wet contact signals;

- Pulse Input (PI): 4 channels, for 0-1kHz speed signal acquisition, suitable for motor speed monitoring scenarios.

- Low-noise Signal Conditioning: Built-in high-precision operational amplifiers and digital filtering circuits, with a common-mode rejection ratio (CMRR) >80dB, effectively suppressing electromagnetic interference (EMI) in industrial fields and ensuring the accuracy of signal acquisition.

3. High Reliability and System Compatibility

- Industrial-grade Hardware Design: The PCB adopts FR-4 epoxy glass cloth substrate (thickness 1.6mm) with 35μm copper foil, featuring high mechanical strength and heat resistance; key solder joints use lead-free soldering process and meet IPC-A-610 Class 3 acceptance standards, reducing the risk of cold solder joints.

- Redundancy Function Support: Supports 1+1 power supply redundant input and key communication channel redundancy. A single-point fault will not affect the operation of the entire system, with a Mean Time Between Failures (MTBF) >800,000 hours (under 40℃ working condition).

- Deep Compatibility with ABB Systems: Equipped with ABB standard backplane bus interface, it can be directly inserted into the slot of Symphony Plus/AC 800M control cabinet, automatically identifying system configurations without manual adjustment of hardware parameters, shortening the integration cycle.

4. Convenient Installation and Maintenance

- Compact Size Design: The board size is 160mm×100mm×25mm (width × height × depth), compatible with 3U industrial racks, supporting snap-on quick installation. It saves space inside the control cabinet and facilitates high-density layout.

- Visual Status Monitoring: The front of the board is equipped with 12 LED indicators, which display real-time information such as power supply, communication, signal status, and fault alarms (e.g., overvoltage, overcurrent, communication interruption), allowing on-site personnel to quickly locate problems.

Support for Online Debugging: Compatible with ABB Control Builder M programming software, it enables online parameter configuration, variable monitoring, and program downloading via USB or Ethernet interface. No board disassembly is required during maintenance, shortening downtime.

Technical Specifications

| Category | Detailed Parameters |

|---|

| Basic Information | Model: GC C960 C103

Ordering Number: 3BHE033067R0103

Product Type: Varnished Printed Circuit Board (PCB VARNISHED)

Compatible Systems: ABB Symphony Plus, AC 800M, Advant OCS |

| Processor & Storage | Processor: 32-bit RISC Industrial CPU, 150 MIPS

Program Storage: 16MB Flash (expandable to 32MB)

Data Storage: 32MB RAM (with backup battery, data retention >72 hours after power-off) |

| Signal Interfaces | Analog Input (AI): 12 channels, 4-20mA/0-10V DC, accuracy ±0.1% FS, 16-bit ADC

Digital Input (DI): 24 channels, 5-30V DC, response time <1ms

Digital Output (DO): 16 channels, relay output (2A/250V AC)

Pulse Input (PI): 4 channels, 0-1kHz, accuracy ±0.1%

Signal Isolation: 2.5kV AC isolation (1min) for AI/PI channels |

| Communication Interfaces | Backplane Bus: 1 channel of ABB-specific bus (100Mbps), compatible with system backplane

Industrial Ethernet: 1 channel of 10/100Mbps Ethernet (RJ45), supports Modbus TCP/IP

Fieldbus: 2 channels of RS485 (half-duplex), supports Modbus RTU, transmission rate 1200bps-115200bps

Debugging Interface: 1×USB 2.0 Type B |

| Power Requirements | Operating Voltage: 24V DC ±15% (supports redundant power input)

Power Consumption: ≤10W under normal operation, ≤15W at maximum load

Power Protection: Overvoltage protection (36V DC), overcurrent protection (1.5A), reverse polarity protection |

| Environmental & Physical Parameters | Operating Temperature: -25℃~+70℃ (operation), -40℃~+85℃ (storage)

Relative Humidity: 5%~95% (no condensation, compliant with IEC 60068-2-3)

Vibration: 5Hz~150Hz, 1.5g acceleration (IEC 60068-2-6)

Shock: 18ms, 20g acceleration (IEC 60068-2-27)

Electromagnetic Compatibility (EMC): EN 61000-6-2 (immunity), EN 61000-6-3 (emission, Class B)

Varnish Specification: Polyurethane three-proof varnish, thickness 25-30μm (IPC-CC-830 Class B)

Dimensions (W×H×D): 160mm×100mm×25mm

Weight: Approx. 380g

Protection Class: IP20 (board-level, enhanced anti-contamination and moisture resistance after varnishing) |

Application Scenarios

With its strong environmental adaptability, the ABB GC C960 C103 3BHE033067R0103 Varnished Printed Circuit Board is widely used in industrial scenarios with high pollution and high humidity:

- Chemical Industry: Used for temperature/pressure control of chemical reactors and status monitoring of corrosive liquid transfer pumps, capable of withstanding acid-base mist in workshops;

- Coastal Power Facilities: Applied in the auxiliary control systems (e.g., circulating water pumps, induced draft fans) of coastal thermal power plants and wind farms, resisting marine salt spray corrosion;

- Water Treatment Industry: Utilized for dissolved oxygen monitoring in aeration tanks of sewage treatment plants and control of sludge dewatering machines, adapting to high-humidity and microbial environments;

- Metallurgical Industry: Employed for control of hydraulic systems in cold rolling workshops of iron and steel plants and current monitoring of electrolytic cells in non-ferrous metal smelting, enduring high dust and high temperatures;

- Food Processing Industry: Used for equipment control (e.g., steam generators) in food sterilization workshops, adapting to high-humidity and cleaning/disinfection environments.

Customers who purchased this product are also browsing the following products:

ABB SPAD346C3 Stabilized Differential Relay

ABB PNI800A Plant Network Interface Module

HONEYWELL LG1093AA24 261A1812P012 ITS ultraviolet (UV) flame sensor

ICS TRIPLEX T8461 Trusted TMR 24 Vdc Digital Output Module

3005319639

3005319639