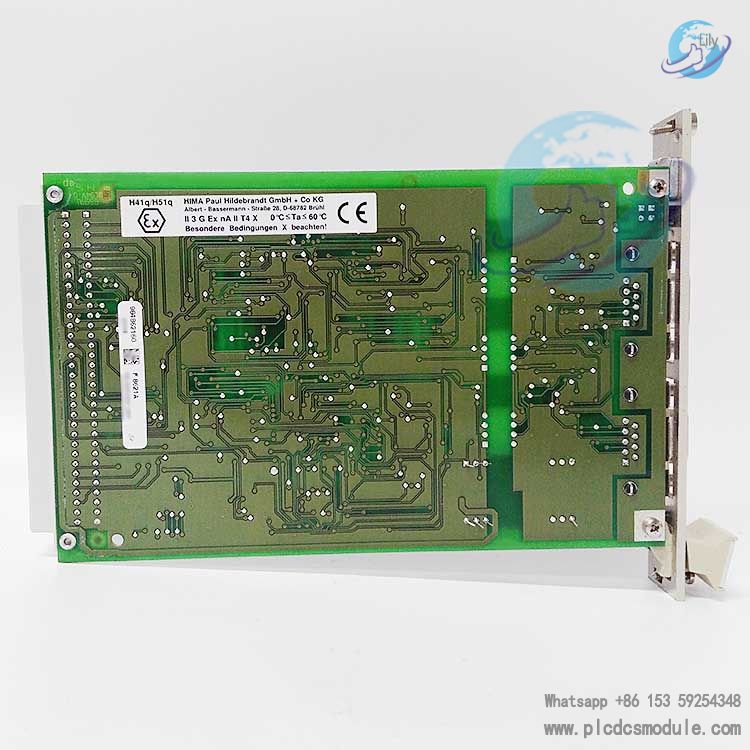

Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. The F8621A 984862160 is a professional coprocessor module belonging to the F-series product line of HIMA. It is core-compatible with the PES H51q system and specifically designed for safety-critical applications in the industrial sector. Boasting high reliability, stable communication capability and flexible memory configuration, this module complies with CE certification standards. It is widely used in scenarios with stringent requirements for equipment safety and data transmission stability, such as petroleum, chemical, power and manufacturing industries. The module enables efficient data interaction with other system modules and auxiliary control of key equipment, thereby providing robust support for the safe operation of industrial automation systems.

related documents

HIMA F8621A.pdf

HIMA F8621A.pdf

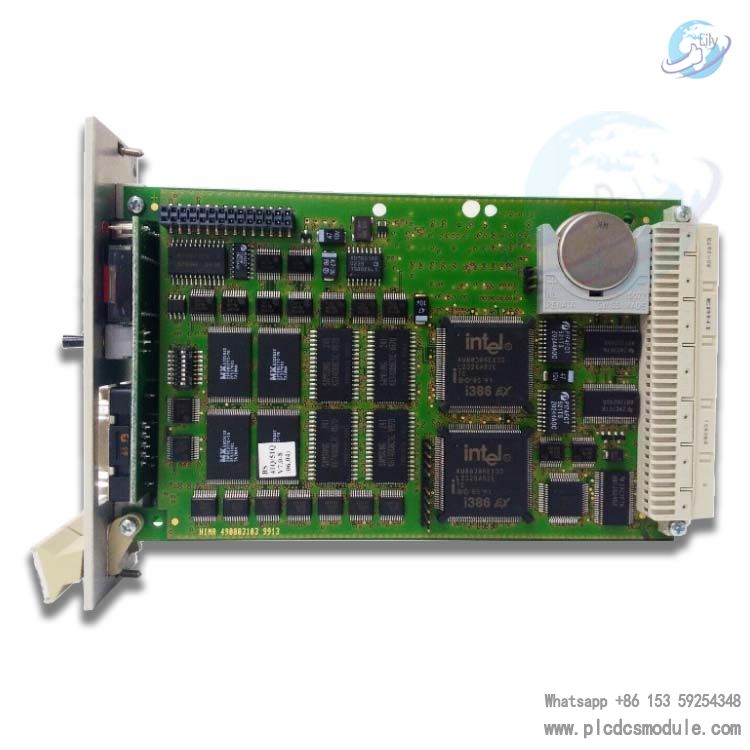

Core Hardware and Performance Configuration

Processor and Clock Frequency

The module is equipped with the independent microprocessor HD 64180, operating at a fixed clock frequency of 10 MHz. It can stably handle data computation and communication task scheduling, meeting the basic requirements for real-time data processing in industrial scenarios and providing core computing power support for the orderly operation of all module functions.

Memory Configuration and Backup Design

Memory Composition

It integrates 384 kbyte of static memory, adopting a dual-chip combination of CMOS-RAM and EPROM. Among them, EPROM is used for storing the operating system and fixed programs, while CMOS-RAM is dedicated to temporary data storage. The clear division of labor between the two chips ensures high efficiency in data storage and retrieval.

Backup Mechanism

The RAM section relies on the power supply monitoring module F 7131 to achieve battery buffering. In emergency situations such as external power outages, battery power supply can maintain the data in RAM without loss, preventing system operation abnormalities caused by critical data damage and improving the security of data storage.

Installation Space and Power Requirements

Installation Space

Featuring a standardized industrial module design, it requires an installation space of 4 TE (a standard unit for industrial equipment mounting). It is compatible with the installation layout of conventional industrial control cabinets, facilitating combined deployment with other HIMA modules and saving internal cabinet installation space.

Power Supply Parameters

The working power supply is 5 V DC, with a stable operating current of 360 mA. Boasting low and stable power demand, it can share the power supply line with other low-power modules in the system, reducing the overall power supply complexity of the system.

Communication Interfaces and Configuration

RS 485 Interface Characteristics

The module is equipped with 2 half-duplex RS 485 interfaces, both with galvanic isolation function. This function can effectively resist electromagnetic interference in industrial environments, reduce the impact of external signals on data transmission, and ensure communication stability. Meanwhile, each interface is equipped with an independent communication processor, which can independently handle data receiving and transmitting tasks of the corresponding interface, avoiding data conflicts when multiple interfaces operate simultaneously and improving communication efficiency.

Transmission Rate and Configuration Method

Software-configurable Rates

It supports 9 fixed transmission rates, namely 300, 600, 1200, 2400, 4800, 9600, 19200, 38400 and 57600 bps. Users can flexibly configure the rate via software according to actual communication distance and data volume requirements, adapting to communication needs in different scenarios.

Hardware-adaptive Rates

It supports reading preset values via the DIP switches on the CU (Central Unit) to realize hardware-linked configuration of transmission rates. This eliminates the need for separate adjustment of module parameters, simplifying the rate matching process during the coordinated operation of multiple devices.

Interface Switches and Pin Definition

Switch Configuration (S1–S4)

To enable the RS 485 function of Interface 1, S1 must be set to on and S2 to off; for Interface 2, S3 must be set to on and S4 to off. Only this combination is valid, and other switch settings will not be recognized by the system, preventing interface malfunctions caused by incorrect configurations.

Pin Assignment

Each RS 485 interface adopts a 9-pin design with clear functional division:

- Pin 3 (A/A) serves as the receive/transmit data A terminal, and Pin 8 (B/B) as the receive/transmit data B terminal — these are the core pins for data transmission.

- Pin 5 (C/C) is the data ground (DGND), ensuring stable signal reference potential.

- Pin 2 (RP) and Pin 6 (VP) provide 5 V voltage (diode-decoupled voltage and positive power supply voltage respectively), which can supply basic power for external auxiliary equipment.

- Pins 1 and 7 are unused.

- Pins 4 (CNTR-A) and 9 (CNTR-B) are control signal terminals, whose specific functions need to be configured in conjunction with system control logic.

The standardized pin definition facilitates on-site wiring and troubleshooting.

Special Functions and System Compatibility

Dual-port RAM Design

The module integrates dual-port RAM as a dedicated channel for data interaction with the second central module. It supports high-speed memory access, greatly reducing data transmission latency, ensuring real-time sharing of critical control data and status information between the two modules, and improving the coordinated operation efficiency of the entire PES H51q system. It is particularly suitable for scenarios requiring multi-module linkage control, such as safety interlocking and emergency shutdown (ESD) systems.

System Compatibility and Safety Design

System Compatibility

It is core-compatible with the HIMA PES H51q system. Its hardware interfaces and communication protocols are fully compatible with other modules of the system, allowing direct integration into the system architecture without additional adapter modules, thus reducing system integration difficulty.

Safety Features

Although SIL certification is not explicitly mentioned, as an integral part of the HIMA safety control system, it inherits the brand’s safety-oriented design philosophy. Combined with functions such as galvanic isolation and battery backup, it indirectly ensures module safety in fault conditions and reduces overall system safety risks caused by module malfunctions.

Customers who purchased this product are also browsing the following products:

HIMA X-AI3201 985210213 Analog input module X-AI 32 01

HIMA F8652E Central Module F 8652E CPU 984865264

HIMA F8650X 984865065 Central module

HIMA 80105 984080105 COMMUNICATION MODULE

3005319639

3005319639