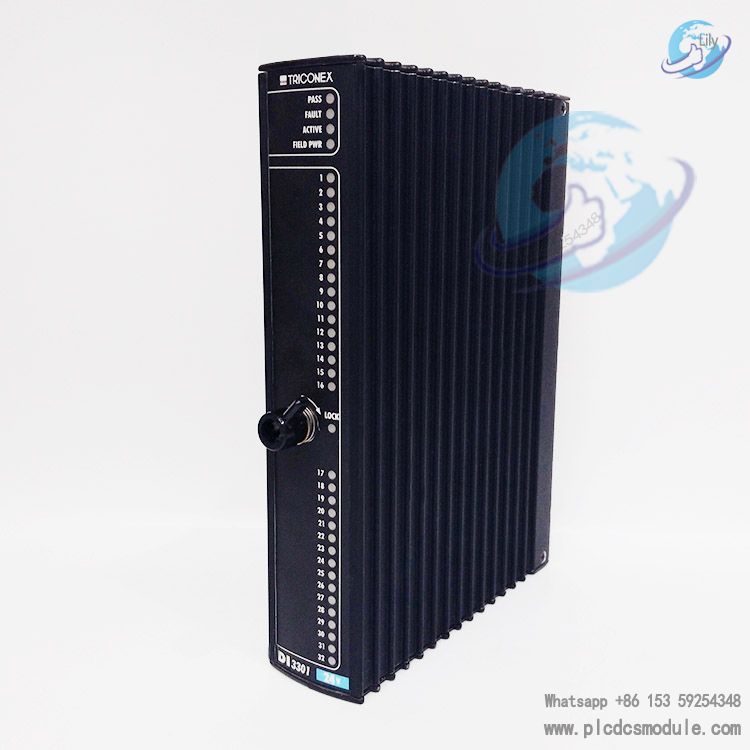

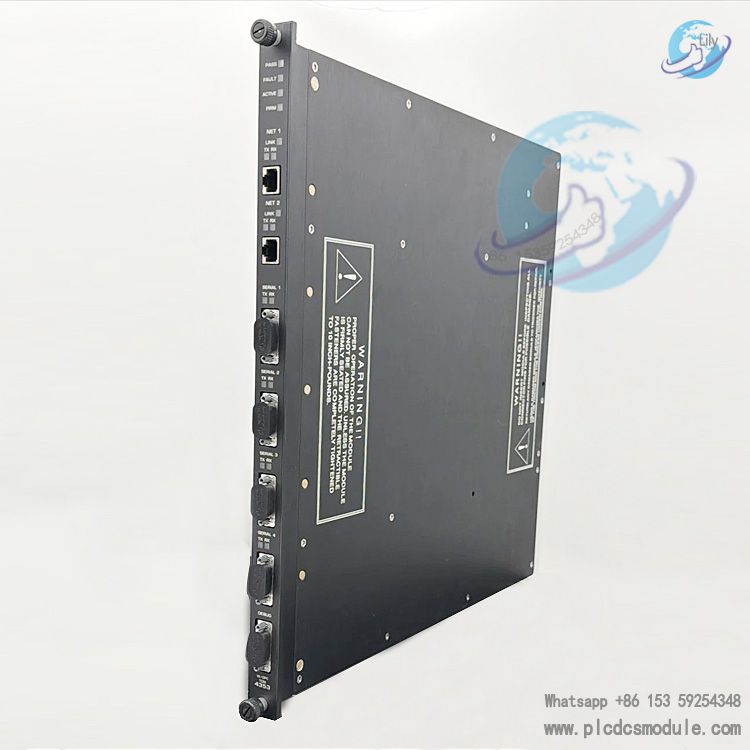

The TRICONEX 3301 Digital Input Module is a core component specifically designed for the TRI-GP controller within the Triconex Safety Instrumented System (SIS). Serving as a critical link between field devices and the control system, it is responsible for acquiring digital signals from sensors, switches, and other field devices, and transmitting them stably and accurately to the TRI-GP controller for subsequent processing and analysis. By precisely monitoring the status of various digital input sources, this module provides a reliable data foundation for safety monitoring, fault Alarm, and interlock control in industrial processes, making it an essential element in ensuring the safe, stable, and efficient operation of high-risk industrial environments.

Tech Docs Download (One-Click Access, No Registration)

Advantageous Features

- High-Reliability Fault-Tolerant Design: When a single channel component fails, it does not affect the normal operation of other channels, reducing the overall failure probability of the system and ensuring the continuous operation of industrial processes.

- Dual Redundant Architecture: The core circuit adopts a dual redundant design. When one set of circuits is abnormal, the standby circuit switches automatically to achieve "uninterrupted" operation, meeting the needs of safety-critical applications.

- Convenient Modular Installation: Adopting a standardized module structure, no complex wiring is required during installation. During maintenance, faulty modules can be disassembled independently without shutting down the entire control system, shortening downtime.

- Hot-Swappable Function: Supports hot swapping of modules. The system remains in normal operation during the replacement process, greatly improving maintenance efficiency and reducing production losses caused by equipment maintenance.

- Intelligent Diagnostic Capability: Built-in real-time diagnostic chip, which can automatically detect problems such as channel signal abnormalities and power failures, and feed back fault information through the controller, facilitating maintenance personnel to quickly locate and solve problems.

- International Safety Certifications: Certified by international safety standards such as UL 61010-1, CE Certification (EN 61010-1), and CSA C22.2 No. 61010-1, adapting to industrial safety regulations in most countries and regions around the world.

- Oil and Gas Industry: Used for onshore pipeline pressure and flow monitoring, offshore drilling platform valve status monitoring, and oil and gas storage tank safety signal collection to prevent risks such as leakage and overpressure.

- Chemical Industry: Adapted for signal collection of temperature and pressure sensors in chemical reactors and distillation towers, and monitoring of raw material ratio switch status in fertilizer production processes to ensure production processes comply with safety regulations.

- Power Industry: In thermal power plants and hydropower stations, it monitors the status of generator cooling systems and circuit breaker opening and closing signals; in substations, it collects digital feedback signals of relay protection devices to improve the stability of the power system.

- Nuclear Power Industry: Applied to the monitoring of pressure and radiation dose sensor signals in the nuclear reactor containment, and the collection of valve status of the emergency cooling system, meeting the strict safety requirements of the nuclear power field.

Other Fields: It can also be used in scenarios such as underground mine ventilation equipment status monitoring, port lifting machinery safety limit signal collection, and pressure switch signal monitoring of digesters in paper mills.

FAQ

Customers who purchased this product are also browsing the following products:

TRICONEX 3211S2 Digital Input module

TRICONEX 3721 Analog Input Module

Honeywell PSU-240516 FS-PSU-240516 Power Supply

FOXBORO FBM207C P0917GY channel isolated 16 input module

3005319639

3005319639