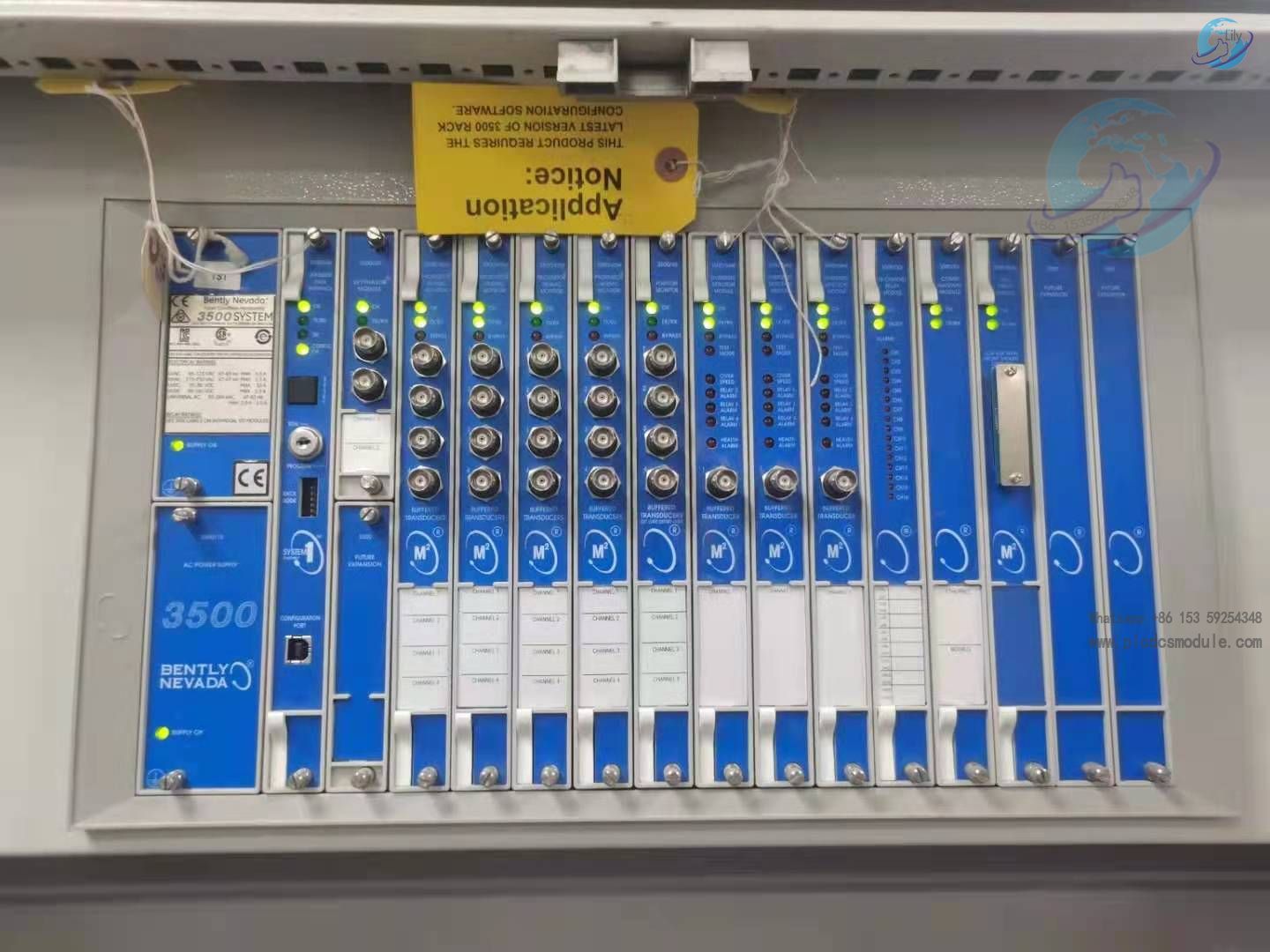

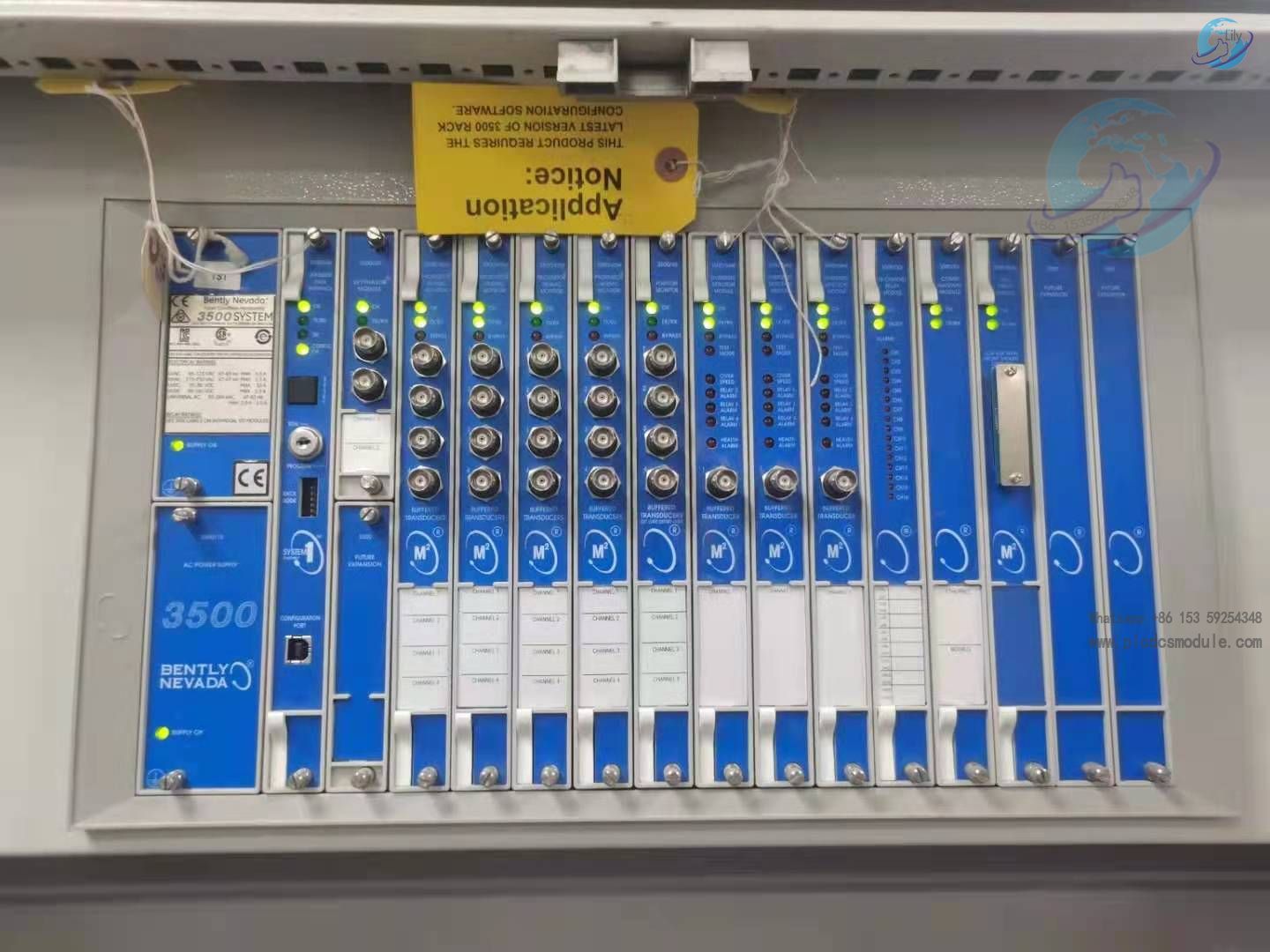

Applications of Bently Nevada 3500 Series in Power, Petrochemical and Chemical Industries and Measuring Points for Vibration Monitoring

As general - purpose equipment, compressors are widely used in many industries such as iron and steel, electric power, metallurgy, chemical engineering, petrochemicals, etc. In scenarios where motors drive compressor units through gearboxes, the Bently Nevada 3500 series vibration protection system plays a key role. The following is a specific configuration example.

A compressor unit usually consists of a motor, a gearbox, and a compressor. In terms of vibration measuring point layout, shell vibration sensors are installed on the front and rear bearing boxes of the motor to measure the absolute vibration of the motor bearings; shell vibration sensors are installed on the low - speed end and high - speed end of the gearbox respectively to measure the absolute vibration of the gearbox; X-Y direction eddy current sensor systems are arranged at the front and rear of the compressor to monitor shaft vibration. In addition, a set of eddy current sensor systems is used to measure the compressor shaft displacement, and another set is used to monitor the keyphasor.

Requirements for measuring point configuration: For keyphasor measurement, each shafting with the same rotational speed in the compressor unit is equipped with one keyphasor measuring point, measured by Bently 3300XL series eddy current sensors; For shaft vibration measurement, each sliding support bearing is equipped with a pair of X/Y direction (installed perpendicular to each other) shaft vibration measuring points, also using Bently 3300XL series eddy current sensors; For shaft displacement measurement, double redundant axial displacement measuring points are configured at each thrust bearing of the compressor unit, completed by Bently 3300XL series eddy current sensors; Bearing vibration is an optional configuration. If configured, two bearing vibration measuring points (horizontal and vertical directions) need to be installed on each rolling support bearing, using Bently 330500 series Velomitor piezoelectric vibration velocity sensors for measurement; For gearbox shell vibration (if applicable), a pair of X/Y direction shell vibration measuring points are configured at the support bearings of the input and output shafts of each gearbox, measured by Bently 330400 series piezoelectric vibration acceleration sensors; Over - speed protection is also an optional configuration. Three redundant over - speed protection measuring points are configured on each compressor unit, measured by 3300XL series eddy current sensors.

Configuration requirements for Bently 3500 series: Each key compressor unit must be equipped with a dedicated Bently 3500 frame, as well as Bently 3500/15 power supply module, 3500/22M transient data interface module, and 3500/25 keyphasor module. For shaft vibration, shaft displacement, bearing vibration, and shell vibration measuring points, Bently 3500/42M monitor modules (if applicable) must be configured; For over - speed protection monitoring points, 3500/53 triple redundant monitor modules must be used. Each monitoring channel (shaft vibration, shaft displacement, and bearing vibration) must be configured with two independent relay output channels, and Bently 3500/32 (4 - channel) or 3500/33 (16 - channel) relay modules can be used, along with a Bently 3500/92 Modbus communication gateway. It should be particularly noted that for units operating in hazardous areas, all 3500 monitor modules connected to on - site signals must have built - in safety barriers, and a 3500/04 intrinsic safety grounding module must be configured in the 3500 frame.

Configuration requirements for vibration monitoring and condition monitoring points: The configuration requirements for keyphasor, shaft vibration, shaft displacement, and bearing vibration measuring points are the same as those for centrifugal compressors driven by steam turbines. In addition, attention should be paid to bearing temperature (if applicable). Each sliding support bearing and thrust bearing must be equipped with bearing pad temperature measuring points, and the working and non - working surfaces of the thrust bearing should be configured with temperature measuring points at the same time; For gearbox shell vibration (if applicable), the configuration method is the same as the former, that is, a pair of X/Y direction shell vibration measuring points are configured at the support bearings of the input and output shafts of each gearbox, measured by Bently 330400 series piezoelectric vibration acceleration sensors.

Configuration requirements for Bently 3500 series: Each key compressor unit is equipped with a dedicated Bently 3500 frame, and each frame is configured with redundant 3500/15 power supply modules and 3500/22M transient data interface modules. For keyphasor measuring points, corresponding 3500/25 keyphasor modules are configured in the Bently 3500 frame of each unit; For shaft vibration, shaft displacement, bearing vibration, and shell vibration measuring points, corresponding 3500/42M monitor modules (if applicable) must be configured; For bearing temperature measuring points, corresponding 3500/60, 61 temperature monitoring modules, or 3500/62 process variable monitoring modules need to be configured. Each monitoring channel (shaft vibration, shaft displacement, and bearing vibration) is configured with two independent relay output channels, and 3500/32 (4-channel) or 3500/33 (16 - channel) relay modules can be used, and each Bently 3500 frame is configured with a 3500/92 Modbus communication gateway. Similarly, for units operating in hazardous areas, all 3500 monitor modules connected to on - site signals must have built - in safety barriers, and a 3500/04 intrinsic safety grounding module must be configured in the 3500 frame.

Configuration requirements for Bently measuring points: The configuration requirements for keyphasor, shaft vibration, shaft displacement, and bearing vibration measuring points are similar to those of the above - mentioned centrifugal compressors. In terms of bearing temperature (if applicable), each sliding support bearing and thrust bearing are equipped with bearing pad temperature measuring points, and the working and non - working surfaces of the thrust bearing should be configured with temperature measuring points at the same time; For gearbox shell vibration (if applicable), the configuration method is still that a pair of X/Y direction shell vibration measuring points are configured at the support bearings of the input and output shafts of each gearbox, measured by Bently 330400 series piezoelectric vibration acceleration sensors.

Configuration requirements for 3500 series: Each key compressor unit is equipped with a dedicated Bently 3500 frame, and each frame is configured with redundant 3500/15 power supply modules and

3500/22M transient data interface modules (RJ45 network interface). For keyphasor measuring points, corresponding

3500/25 keyphasor modules are configured in the Bently 3500 frame of each unit; For shaft vibration, shaft displacement, bearing vibration, and shell vibration measuring points, corresponding 3500/42M monitor modules (if applicable) must be configured; For bearing temperature measuring points, corresponding 3500/60, 61 temperature monitoring modules, or 3500/62 process variable monitoring modules need to be configured. Each monitoring channel (shaft vibration, shaft displacement, and bearing vibration) is configured with two independent relay output channels, and

3500/32 (4 - channel) or

3500/33 (16 - channel) relay modules can be used, and each Bently 3500 frame is configured with a 3500/92 Modbus communication gateway. For units operating in hazardous areas, all 3500 monitor modules connected to on - site signals must have built - in safety barriers, and a 3500/04 intrinsic safety grounding module must be configured in the 3500 frame.

Configuration requirements for measuring points: In terms of multi - event keyphasor, a multi - event keyphasor wheel (MEW) is installed at the drive end of the reciprocating compressor to measure the keyphasor reference signal. The wheel can be a Bently standard multi - event wheel (MEW), or specially customized and designed by the reciprocating compressor manufacturer in combination with its own equipment structure design characteristics in accordance with Bently's best engineering practice experience for multi - event keyphasor wheels. The multi - event keyphasor signal is measured by Bently 3300XL series eddy current sensors. For crankcase vibration measurement, a vibration velocity sensor is configured on the horizontal axis of each main bearing between the two cylinder rows of the reciprocating compressor crankcase. When the operating speed is higher than 500rpm, Bently 330500 series Velomitor piezoelectric vibration velocity sensors are used; when the operating speed is lower than 500rpm, Bently 190501 Velomitor CT piezoelectric vibration velocity sensors are used. For crosshead vibration monitoring, redundant acceleration sensors are configured on the vertical plane at the midpoint of each cylinder crosshead movement, measured by Bently 330425 acceleration sensors to monitor impact events of reciprocating components. For piston rod position measurement, a pair of mutually perpendicular piston rod position measuring points are configured in the horizontal and vertical directions of each cylinder perpendicular to the piston rod plane, measured by Bently 3300XL series eddy current sensors. Bently recommends this as the preferred method for piston rod measurement. For cylinder dynamic pressure measurement, two cylinder pressure measuring points (suction and exhaust) are configured on each cylinder, measured by Bently 165855 cylinder pressure sensors. For bearing vibration measurement, each main bearing is configured with a velocity sensor. When the rotational speed is higher than 500rpm, Bently 330500 series Velomitor piezoelectric vibration velocity sensors are used; when the rotational speed is lower than 500rpm, Bently 190501 Velomitor CT piezoelectric vibration velocity sensors are used. In addition, each main bearing is configured with a temperature sensor to measure bearing temperature, and each valve (suction valve and exhaust valve) is configured with a temperature sensor to measure valve temperature; For gearbox shell vibration (if applicable), the configuration method is the same as before, measured by Bently 330400 series piezoelectric vibration acceleration sensors; For motor bearing vibration, two bearing vibration measuring points (installed in horizontal and vertical directions) are configured on each rolling support bearing, measured by Bently 330500 series Velomitor piezoelectric vibration velocity sensors.

Configuration requirements for Bently 3500 series: Each key compressor unit is equipped with a dedicated Bently 3500 frame, as well as Bently redundant 3500/15 power supply modules and 3500/22M transient data interface modules (RJ45 network interface). Corresponding 3500/25 keyphasor modules are configured in the Bently 3500 frame of each unit; For reciprocating compressor crankcase vibration, crosshead vibration, and bearing vibration, corresponding

3500/70M monitor modules are configured; For piston rod position measuring points, corresponding

3500/72M monitor modules need to be configured; For reciprocating compressor cylinder dynamic pressure, corresponding 3500/77M monitor modules are configured; For bearing temperature and valve temperature measuring points, corresponding 3500/60, /61, /62, or /65 monitor modules need to be configured; For gearbox shell vibration and motor bearing vibration, corresponding 3500/42M monitor modules need to be configured. Each monitoring channel is configured with two independent relay output channels, and 3500/32 (4 - channel) or 3500/33 (16 - channel) relay modules can be used, along with a Bently 3500/92 Modbus communication gateway. For units operating in hazardous areas, all 3500 monitor modules connected to on - site signals must have built - in safety barriers, and a 3500/04 intrinsic safety grounding module must be configured in the 3500 frame.

The Bently 3500 rotating machinery vibration protection instruments and condition monitoring systems strictly comply with the American API 670 standard, ensuring high quality and reliability in applications in power, petrochemical, and other industries, and providing strong guarantees for the stable operation of equipment.

3005319639

3005319639