Turbine control systems are vital for the efficient and safe operation of power plants. Among the widely used control systems, GE's Speedtronics Mark IV and Mark V are regarded as industry benchmarks. This article delves into the characteristics and improvements of these two generations of turbine control systems, revealing the development and progress brought by the Mark V system.

I. Overview of GE Speedtronics Mark IV

GE's Speedtronics Mark IV is a groundbreaking control system that introduced automation and advanced monitoring capabilities for gas and steam turbines. Launched in the late 1980s, the Mark IV became an industry standard, featuring a range of functions to enhance turbine performance, reliability, and efficiency.

Key Features of GE Speedtronics Mark IV

Control Algorithms: The Mark IV employs sophisticated control algorithms to optimize turbine operation, ensuring stable and efficient power generation.

Human-Machine Interface (HMI): The system is equipped with an early-version HMI, allowing operators to monitor and control turbine parameters through a graphical interface.

Diagnostic Capabilities: The Mark IV introduced advanced diagnostic tools for rapid problem identification and resolution, minimizing downtime and improving maintenance practices.

Redundant Design: The Mark IV system incorporates redundancy for critical components, enhancing the overall reliability of the turbine control system.

II. Evolution to GE Speedtronics Mark V

Building on the success of Mark IV, GE launched the Speedtronics Mark V system, marking a significant leap in turbine control technology. Introduced in the early 1990s, the Mark V brought multiple improvements to further enhance turbine control and performance.

Notable Advancements of GE Speedtronics Mark V

Digital Control Platform: Mark V shifted to a fully digital control platform, replacing analog components with digital ones. This transition improved control precision, speed, and overall system reliability.

Upgraded Human-Machine Interface: Mark V introduced a more intuitive and user-friendly HMI, enabling operators to view and control turbine parameters more clearly. The graphical interface became more sophisticated, facilitating faster decision-making.

Advanced Diagnostic & Predictive Tools: The Mark V system expanded diagnostic capabilities by integrating predictive maintenance tools, allowing operators to anticipate potential issues and proactively plan maintenance.

Integrated Control & Protection: Mark V seamlessly integrated control and protection functions, enhancing the overall safety and response speed of the turbine control system.

III. Comparative Analysis

Performance: By shifting from analog to digital control, Mark V significantly improved control precision and speed, achieving optimal overall turbine performance.

Reliability: Mark V's enhanced diagnostic and predictive tools boost reliability by supporting proactive maintenance, reducing unplanned downtime.

User Interface: Mark V's advanced human-machine interface offers a more user-friendly experience for operators, facilitating faster decision-making and quicker responses to changing operational conditions.

IV. Leveraging Call GTC India for Enhanced Support

In the realm of turbine control systems, reliable support and maintenance services are critical to ensuring the seamless operation of GE Speedtronics Mark IV and Mark V systems. Call GTC India specializes in providing comprehensive solutions tailored to power plants utilizing these advanced control systems.

Remote Assistance & Troubleshooting:

Call GTC offers real-time remote support to address any issues or concerns related to Mark IV and Mark V systems promptly. This includes diagnostic troubleshooting, configuration adjustments, and on-demand technical guidance to minimize downtime.

24/7 Technical Support:

Recognizing the continuous operation of turbines, Call GTC provides round-the-clock technical assistance. This ensures that plant operators have immediate access to expert support, enhancing system reliability and reducing unplanned outages.

Software Updates & Upgrades:

As technology evolves, system upgrades become essential for optimizing performance. Call GTC facilitates seamless integration of the latest software versions, ensuring access to cutting-edge features, security enhancements, and regulatory compliance.

On-Site Support & Maintenance:

For situations requiring physical intervention, Call GTC deploys certified engineers and technicians to power plants. On-site services include system inspections, preventive maintenance, component replacements, and performance tuning to maximize system longevity.

Proactive Monitoring & Predictive Maintenance:

Call GTC employs advanced monitoring tools to assess the health of Mark IV and Mark V systems continuously. By leveraging predictive maintenance strategies, potential issues are identified and addressed before they escalate, minimizing disruptions and extending equipment lifespan.

Customized Service Plans:

Understanding that each power plant has unique requirements, Call GTC offers tailored service packages. These plans are adaptable to specific operational needs, ensuring alignment with the plant’s efficiency goals, budget constraints, and regulatory requirements.

The GE Speedtronics Mark IV and Mark V systems have been instrumental in shaping modern turbine control technology. The transition from Mark IV to Mark V represents a significant technological leap, with the Mark V introducing a fully digital platform, enhanced human-machine interfaces, and advanced diagnostic capabilities. These improvements have set new standards in performance, reliability, and user experience. As power generation continues to evolve, these innovations will remain pivotal in optimizing turbine operations, ensuring safe and efficient energy production.

The GE Speedtronics Mark V system is primarily applied in the following fields:

Power Generation Sector

Gas Turbine Power Generation: It controls the starting, operation, and shutdown processes of gas turbines to ensure optimal performance. By integrating advanced control algorithms, fault diagnosis, and predictive maintenance functions, it significantly enhances the efficiency and reliability of gas turbines, optimizes performance, and improves energy utilization efficiency and output power.

Steam Turbine Power Generation: It enables comprehensive monitoring of steam turbines, achieving load synchronization and application based on local or regional power dispatch commands. It supports various pressure control modes (e.g., inlet pressure, extraction pressure, back pressure) and provides overspeed protection during load shedding and emergencies. It also tests steam valves and other critical protection functions.

Combined Cycle Power Generation: It provides universal operator training and control for steam turbines and gas turbines in STAG™ combined cycle power plants, enabling collaborative operation of the two turbines to enhance the efficiency and reliability of combined cycle power generation.

Industrial Sector

Large Industrial Unit Drive: Used to drive large industrial units such as compressors and fans. Through precise control, it ensures stable operation of units under different working conditions to meet the power demand in industrial production processes.

Industrial Process Control: In complex industrial production processes (e.g., petrochemical, metallurgy), it participates in controlling turbine-related technological processes to ensure production stability and product quality consistency.

Energy Management Sector

Power Grid Frequency and Voltage Regulation: According to grid demands, it rapidly adjusts turbine output power and voltage to participate in grid frequency and voltage regulation, maintaining grid stability.

Distributed Energy Systems: In distributed energy systems (e.g., small hydropower stations, biomass power plants), it effectively controls turbines to achieve efficient energy conversion and utilization, improving the overall performance of distributed energy systems.

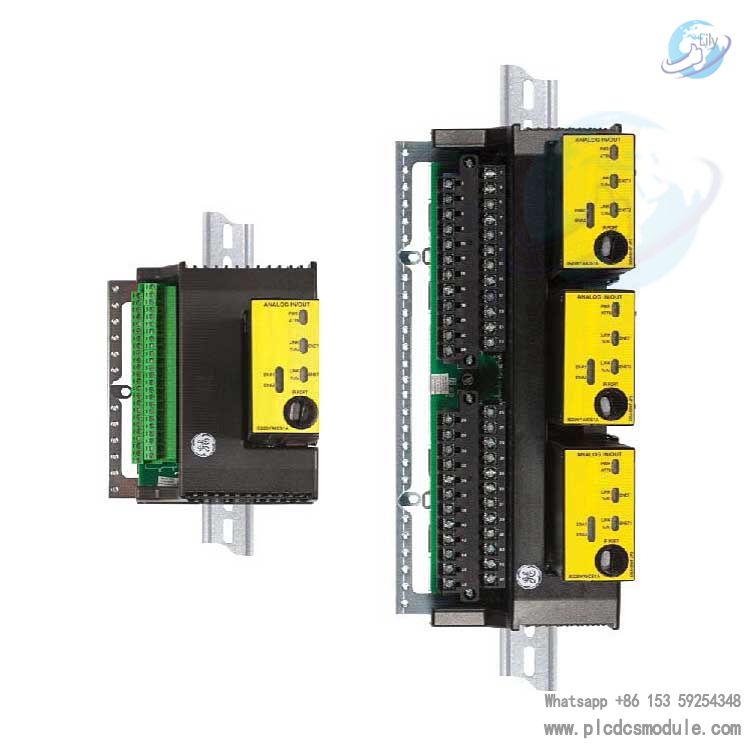

Here are some of the product models of the Mark IV and Mark V gas turbine card modules:

Mark IV

DS3800DFXX1B1B: It is a circuit board module component in the Mark IV turbine control system and serves as an interface board to connect the system to an external network.

DS3800HRMD: It is a board in the Mark IV system, which has 126 resistors, 6 light - blue diodes, 35 orange diodes, 3 metal diodes, 1 black diode, 1 red diode, 20 groups of metal pins called jumper ports, and 44 EPROMs and EEPROMs.

Mark V

DS200TCCAG1BAA: It is an I/O TC2000 analog board.

DS200PTBAG1BBA: General - purpose board for Mark V Speedtronic.

IS215CLEH1A: GE application control layer module.

DS200TCPAG1AJD: GE turbine control processor board.

DS200LDCCH1: GE Fanuc LAN control card drive board.

DS200PCCAG5ACB: General Electric power connect card.

DS200DDTBG2ABB: GE - LCI auxiliary I/O terminal board.

DS3800HCMC1A1B: Gas turbine daughter board.

DS200DTBAG1AAA: GE - digital contact terminal board.

DS3800NSFE1E1B: General Electric PCB circuit board.

DS200TBQCG1ABB: RST analog termination board.

DS200RTBAG3AEB: Relay terminal module.

DS3800NMEC1K1K: Exciter control board.

DS200PCCAG10ACB: Power connect card.

IS200WETBH1BAA: GE printed circuit board.

IS210AEAAH1BHB: GE alternative energy application board.

DS200SDCCG4AGD: GE Mark V drive control card.

DS200SLCG3AFG: GE LAN communication board.

DS200TCTGG1A: GE GT/TMR simplex trip board.

DS200TCDAH1BG: GE digital I/O board.

DS200TBQCG1A: GE analog I/O termination module.

DS200TCPSG1A: GE DC input power supply circuit board.

DS200TCPDG1B: GE power distribution board.

IS215UCVEM01A: GE UCV controller module.

3005319639

3005319639