Different equipment classifications correspond to different monitoring devices.

| Category | Description | Economic Factors | Recommended Monitoring Technologies |

|---|---|---|---|

| Level 1 "Critical Type" | Assets that have a significant or comprehensive impact on factory output; Or have extremely high maintenance costs; Or have significant safety hazards. Faults may occur suddenly and not necessarily with warnings. | Fault costs are extremely high —— Due to production losses, repair or replacement costs, environmental impacts, or health and safety impacts, each incident or day usually amounts to millions of US dollars. Typical examples include gas/steam turbines, generators, and large compressors. The economic rationality of monitoring such assets lies in avoiding production losses, reducing maintenance costs, and protecting lives, the environment. | Protection and condition monitoring Continuous online monitors (e.g., 3500, ADAPT, Orbit 60) |

| Level 2 "Basic Type" | Assets that have a relatively small impact on factory output; Or have moderate maintenance costs; Or have relatively minor health and safety hazards. Faults may occur relatively quickly (within minutes or hours), but there are usually some warnings. | Similar to the economic factors of critical equipment, but on a smaller scale. Typical examples include cooling fans and process pumps (especially pumps transporting flammable liquids). The economic rationality of monitoring such assets is the same as that for critical equipment, but on a smaller scale. | Frequent condition monitoring (without protection function *), Continuous or scanning monitors (e.g., Trendmaster® , vbOnline Pro or Ranger Pro) |

| Level 3 "General Type" | Assets that have a minimal impact on factory output; Or have limited maintenance costs; Or have minor safety consequences. Faults usually have warnings weeks or months in advance. | Such assets usually have one or more spare parts that can be put into use immediately (thus the risk of production loss is relatively small). However, due to the large number of such assets, they account for a large proportion of the annual maintenance costs. The economic rationality of condition monitoring for such assets mainly lies in reducing maintenance costs. | Regular condition monitoring Manual data collection (e.g., SCOUT series portable instruments) |

| Level 4 "Non-critical Type" | Assets not directly related to the process; Or the repair/replacement costs are negligible; Or have no safety consequences. | Fault costs do not exceed the monitoring costs (or the payback period is too long). Using post-fault repair or scheduled maintenance (rather than predictive maintenance) methods is considered the most cost-effective. | No need for condition monitoring instruments Carry out scheduled maintenance or post-fault repair |

1.Bently Nevada continuous online monitoring

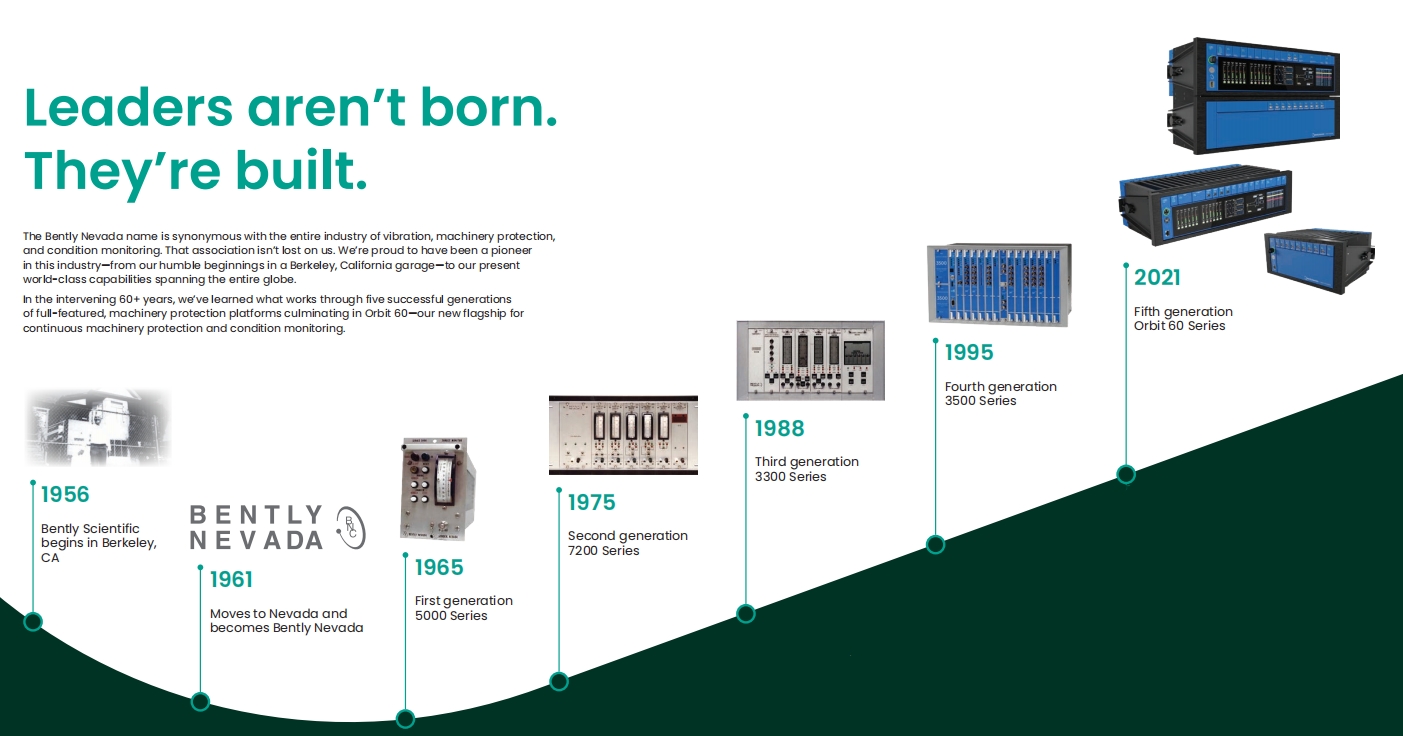

1.1Orbit 60 Series Machinery Monitoring and Protection System

1.Research Requirements:

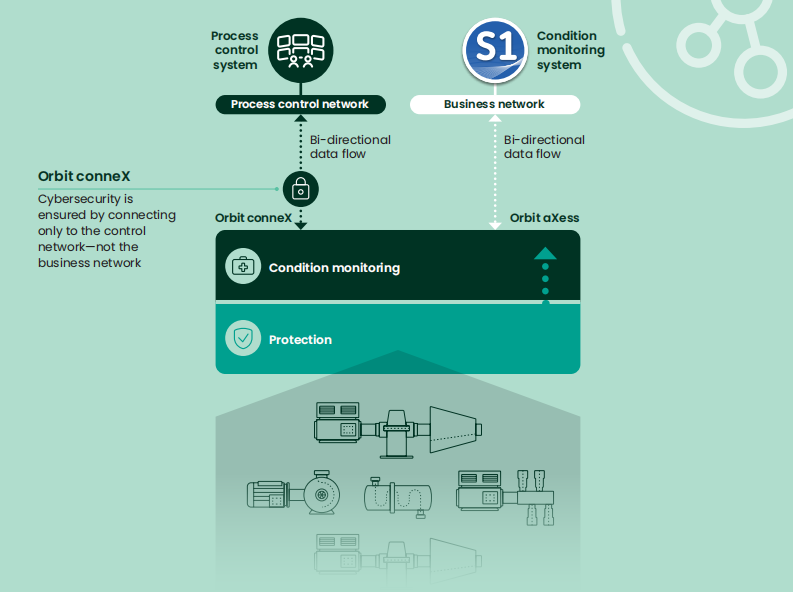

A cybersecurity solution for machinery protection and condition monitoring. This solution not only meets the needs of mechanical engineers but also addresses the requirements of OT and IT fields where data must be transferred.

It reduces installation costs by allowing more flexible choices in system placement and the number of wires that need to be routed.

It provides a simpler and more cost-effective way to transmit machinery data to process control and monitoring ecosystems.

Three new concepts to embody these features:

Orbit conneX, Orbit aXess, and Orbit Xtend

In the 1960s and 1970s, connections to monitors in the process control world included recorder outputs and relays. In the 1980s, digital communication emerged with protocols like Modbus, enabling all these signals to be transmitted via a single cable. Over the next three decades, improvements were made with new protocols and physical media, but one issue remained: one interface was used to move data from the monitoring system to the process control system or historical database, while a completely separate interface was used to move process data in the opposite direction—into the condition monitoring system.

This meant at least two interfaces were required. Two cables needed to be run. Two interfaces required maintenance. Two programmed gateways. Our Orbit conneX™ technology enables bidirectional data movement. A single interface can import all data into the process control environment while acquiring thousands of process data points from the process control environment into the condition monitoring environment. One interface. One gateway. One set of cables. A great innovation. Orbit conneX simplifies your world and saves you money.

We call it Orbit aXess™ technology. It allows protection and condition monitoring functions to coexist in the same rack and use the same I/O, while remaining fully independent of each other. The protection component can publish its data for use by the condition monitoring system, but there are no physical circuit board traces that allow data to flow back from the condition monitoring component to the protection component. Data moves in one direction.

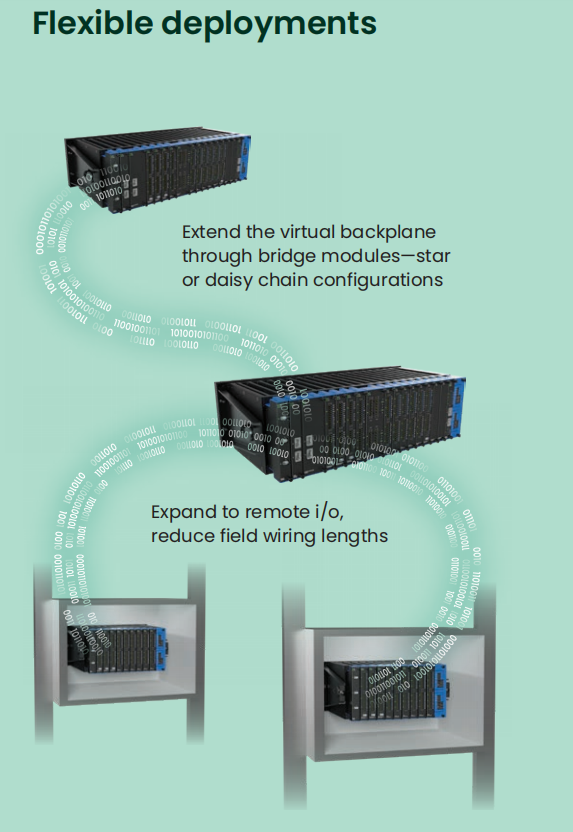

Our Xtend technology allows you to connect multiple chassis with a virtual digital backplane using copper cable* or fiber optics. It is fast. It is secure. And it is flexible. As a result, the Orbit 60 can be deployed not only as a traditional "single" rack but also as distributed racks, where I/O is located near the machinery to significantly redu

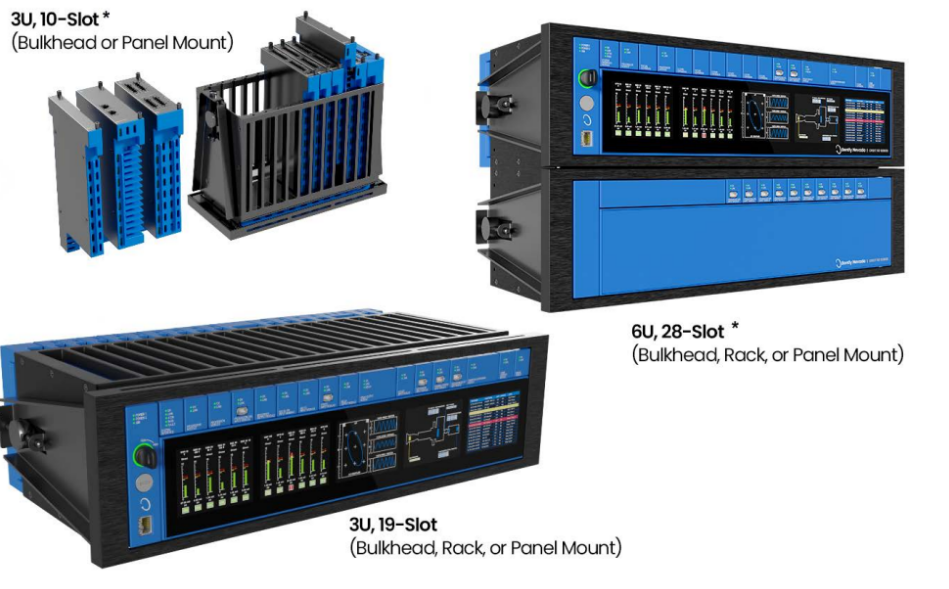

60R/CHA System Chassis: Provides mounting brackets for Orbit 60 Series modules, used in machinery monitoring and protection.

60R/PIM Power Input Module: Connects external power supplies to the Orbit 60 system.

60X/XPS System Power Supply: Available in AC or DC configurations, providing power for the Orbit 60 system.

60R/SIM01 System Interface Module: Delivers general functions for the entire Orbit 60 system and interfaces with displays and software.

60R/PPM01 Protection Processing Module: Offers protection functions based on any combination of dynamic, static, and CGM inputs.

60R/INP Static Input Module: Features 6 channels, capable of accepting RTD, TC, wet or dry discrete contacts/signals, and process variable signals. It includes three models: RTD/TC Temperature Input Module (RTD), Isolated TC Temperature Input Module (ITC), and Isolated Process Variable/Discrete Input Module (PVD).

60R/REC01 Recorder Output Module: Equipped with 8 channels, providing proportional analog outputs of measured variables and fully programmable.

60R/INP Dynamic Input Module: Available with either positive or negative input options, supporting commercially available sensors, and suitable for speed or keyphasor signals.

60X/EXD External Display: A touchscreen display designed for excellent viewing quality in industrial applications.

60R/CMM01 Condition Monitoring Module: Provides fully integrated condition monitoring functions for the Orbit 60 system.

60R/RLY Relay Output Module: A set of relays that can be programmatically activated based on alarm conditions defined in other modules.

60R/INP06 Keyphasor Input Module: Recommended for use in cases where shaft rotational speed exceeds 12,000 rpm.

60R/CGW Communications Gateway Module: Transmits measured values, alarms, statuses, and configuration information to external hosts.

60R/BRG01 Bridge Module: Allows multiple Orbit 60 chassis to be connected together, enabling flexible deployment.

60R/INP10 AC LVDT Input Module: A 4-channel module used for valve position and casin

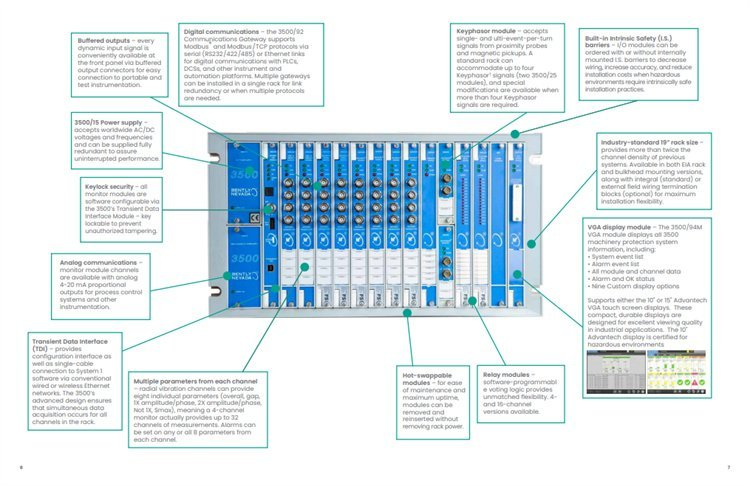

1.2 3500 Series Machinery Monitoring and Protection System

Display of Some Products in the 3500 Series

3500/15 Power Supply Module

3500/22 TDI Frame Interface Module

3500/25 Keyphasor Monitor Module

3500/32 4-Channel Relay Monitor Module

3500/32M 4-Channel Relay Monitor Module

3500/33 16-Channel Relay Monitor Module

3500/40 Displacement Monitor Module

3500/40M Displacement Monitor Module (REBAM as Custom Channel)

3500/42 Displacement/Seismic Monitor Module

3500/42M Displacement/Seismic Monitor Module (REBAM and Circular Acceptance Area as Custom Channels)

3500/44 Aero-Derivative Gas Turbine Monitor Module

3500/44M Aero-Derivative Gas Turbine Monitor Module (Multi-Mode as Custom Channel)

3500/45 Position Monitor Module

3500/46M Hydro Turbine Monitor Module (System 1 supports water-electric gap channels and multi-mode gap channels)

3500/50 Tachometer Monitor Module

3500/50M Tachometer Monitor Module

3500/60 Temperature Monitor Module without Recorder

3500/61 Temperature Monitor Module with Recorder

3500/62 Process Variable Monitor Module

3500/64M Dynamic Pressure Monitor Module

3500/65 16-Channel Temperature Monitor Module

3500/70M Vibration/Speed Monitor Module

3500/72M Piston Rod Position Monitor Module (System 1 supports rod position paired channel 2 and rod position single channel 2.)

3500/77M Cylinder Pressure Monitor Module

Supported Custom Monitors

3500/46M Hydro Turbine Monitor Module

3500/53 Overspeed Detection Monitor Module

3500/63 Gas Detection Monitor Module

3500/82 Motor Stator Insulation Monitor Module

The following modules cannot display icons or bar graphs but provide alarms and events:

3500/20 Frame Interface Module

3500/34 TMR Relay Module

3500/90 Communication Gateway Module

3500/91 Communication Gateway Module

3500/92 Communication Gateway Module

3500/93 Display Interface Module

3500/94 VGA Display Monitor

1.3Bently Nevada 3500 ENCORE is the cost-effective solution for non-intrusive upgrades of existing 3300 monitoring systems.

The 3500 ENCORE chassis supports upgrades for 6P, 8P, 10P, 12P, and 14P 3300 racks. The chassis consists of an EMI cage, a backplane, and interface modules. The rack upgrade utilizes existing 3300 I/O modules and power input modules. The interface modules are installed between the old backplane and the new backplane. These are used to reduce the possibility of damaging the old backplane during the upgrade process and serve as part of the shielding for the new system. The upgraded rack provides slots for a single power supply and system monitor at the leftmost rack position, which are reserved specifically for these modules. The remaining slots in the rack can accommodate any combination of monitors. All modules are inserted into the new backplane of the chassis, consisting of a main module and an associated I/O module.

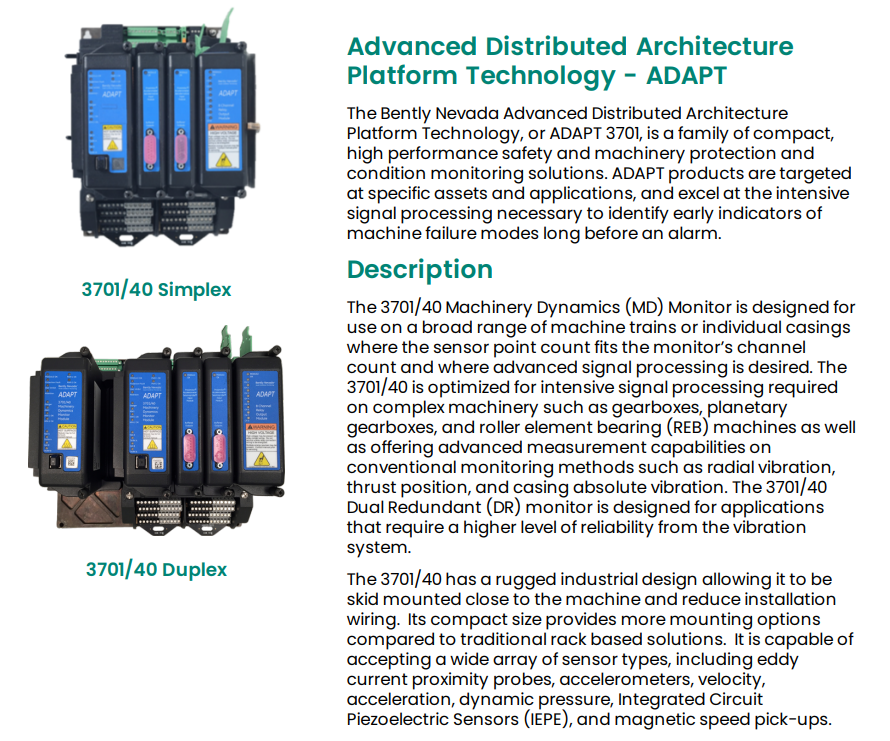

1.4 ADAPT3701

The ADAPT 3701 series products are mainly positioned for critical and highly critical equipment that require continuous online condition monitoring and protection. Different from the 3500 frame, the ADAPT 3701, with its compact structure and number of channels, is suitable for condition monitoring and protection of units that require fewer measuring points.

The ADAPT 3701 series mainly includes three vibration monitoring and protection systems for different applications: 3701/40, 3701/44, and 3701/46.

3701/40 ADAPT MD is a general-purpose condition monitoring and protection system for critical rotating units in the ADAPT product family.

3701/44 ADAPT Aero is a condition monitoring and protection system specially designed for aero-derivative gas turbines. It can be applied to the condition monitoring and protection of aero-derivative gas turbines and driven equipment in associated areas.

3701/46 ADAPT Hydro is a vibration monitoring and protection system specially designed for hydro turbines.

3005319639

3005319639