Our Bently design, installation, and maintenance services integrate hardware and software to deliver fully customized factory solutions. From design and testing to configuration and commissioning, we ensure turnkey readiness—boosting reliability for advanced industrial operations.

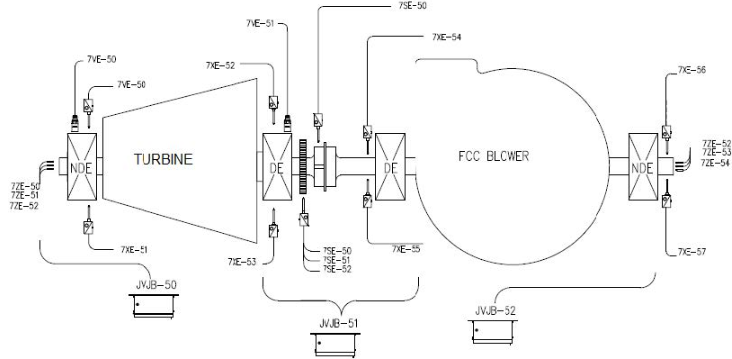

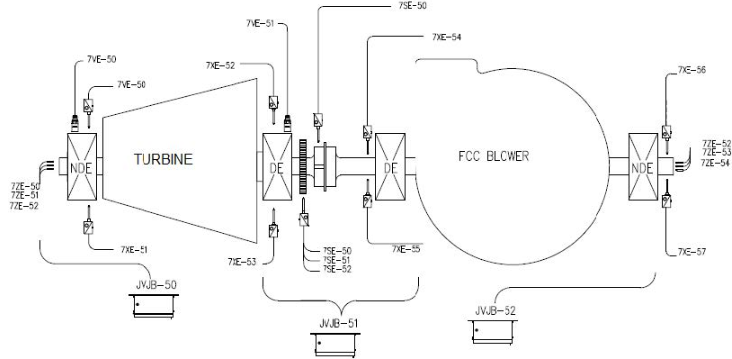

We install sensors (e.g., proximity probes) and modified bearing housings for:

- Reciprocating compressors (dedicated monitoring)

- Turbines, fans, water wheels, and more

All solutions connect to specialized systems like:

- 3500 Rack

- DSM

- 1900/65A Field Displays

These setups enable proactive machine protection and diagnostics to reduce downtime.

Our end-to-end offerings include:

System Design & Installation

- Custom mechanical modifications (sensor mounts, cabling, junction boxes)

- Integration of monitoring systems, software, and industrial IT infrastructure

Project Management

- Site supervision for electrical/mechanical work (e.g., turbine/equipment teardown/reassembly)

- Modular solutions for new builds or retrofits—adapting to oil/gas, power generation, pulp/paper, and process industries

Specialized Expertise

- Turbine Supervisory Instrumentation (TSI) systems for rapid startup/shutdown cycles

- Compliance with factory IT standards, hazardous-area certifications (e.g., NEPSI, ATEX), and regional regulatory requirements

Training & Support

- On-site or global training center courses for system operation

- Factory and field acceptance testing to ensure compliance

We partner with OEMs to ensure safety and compatibility for all machinery types. Our services align with:

- Local hazardous-area codes (e.g., China’s NEPSI, EU ATEX/IECEx)

- Factory IT protocols and national certification bodies

From full turnkey projects to “à la carte” support (e.g., internal plant resource coordination), we tailor solutions to your scope. Benefit from:

Decades of industrial experience

Strict adherence to safety, timelines, and budget

Keywords: Bently vibration monitoring, industrial machinery installation, turbine TSI systems, hazardous area compliance, reciprocating compressor monitoring, factory IT integration, NEPSI/ATEX certification

SEO Notes: Prioritize technical keywords (e.g., “TSI systems,” “hazardous area compliance”) and industry-specific terms (e.g., “oil/gas,” “power generation”) to align with engineering/plant operations search intent. Use headers, bullet points, and bolded terms to improve crawlability.

3005319639

3005319639