1. Industry Background and Product Overview

Against the backdrop of sustained global growth in wind power demand and the growing importance of renewable energy, the power rating of large-scale wind turbines continues to rise. Medium-voltage systems have emerged as a superior choice, thanks to their advantages of reducing power transmission system losses to boost electricity generation and eliminating costly cable lines to lower installation costs.

The PCS6000 Medium-Voltage Full-Power Wind Turbine Converter launched by ABB leverages mature technology to support the efficient operation of large-scale wind turbines, effectively reducing the Levelized Cost of Electricity (LCOE). With a maximum power capacity of 12MW, it injects strong momentum into the development of the wind power industry.

2. Product Matching and Cost Advantages

The PCS6000 medium-voltage wind turbine converter is perfectly compatible with large-scale offshore wind turbines, boasting a maximum power of up to 12MW and adaptability to both permanent magnet generators and induction generators. Its compact design minimizes floor space, supporting both nacelle-mounted and tower-mounted installations to flexibly meet diverse installation requirements.

In terms of cost control, the PCS6000 delivers outstanding performance. By enhancing equipment availability, ensuring high operational efficiency, complying with advanced grid codes, and simplifying maintenance processes, it significantly reduces the LCOE, helping wind power projects achieve economical and efficient operations.

3. Mature Technology and Wide-Ranging Applications

This converter is based on ABB’s medium-voltage inverter technology, which has been widely used in thousands of applications worldwide. It has earned a strong reputation for reliable operation in harsh environments, playing a key role not only in industrial and propulsion drive systems, railway power grids, static var compensation, and battery energy storage but also in high-demand application scenarios such as tidal power generation.

DATA SHEET

Since the delivery of the first PCS6000 unit in 2006, its mature technology has been continuously validated by the market, providing stable and reliable power solutions for various high-demand scenarios.

4. Comprehensive Services and Professional Support

Adhering to the philosophy of "more than just providing products," ABB offers high-quality full-lifecycle services for PCS6000 users. From the early evaluation stage of wind turbines to the final operation stage of wind farms, ABB’s professional team provides first-class customer consulting, technical support, training, and maintenance services throughout the process.

ABB’s converter specialists cover all areas of the electrical system chain from power generation to grid connection, with in-depth professional knowledge. In lifecycle management, the high-caliber service team enables remote monitoring through supporting software tools, maximizing equipment value by ensuring fault-free operation and improving availability.

5. Core Features

The PCS6000 medium-voltage full-power wind turbine converter boasts a range of core features that comprehensively guarantee equipment performance and efficiency:

- High Power Output: Full-power output of up to 12MW meets the needs of large-scale wind turbines.

- Medium-Voltage Technology: Effectively enhances operational efficiency.

- Fewer and Long-Lasting Components: Ensures high equipment availability and reduces failure risks.

- Low Lifecycle Cost: Saves costs for users in long-term operation.

- Modular Design: Facilitates easy customization and flexible adjustment according to different needs.

- Advanced Support and Remote Service Tools: Further improve equipment reliability, availability, and performance, safeguarding stable operation.

6. Outstanding System Performance

With a variety of advanced features, the PCS6000 ensures efficient and reliable operation of wind turbines while strictly complying with grid codes. Its specific performance advantages are as follows:

6.1 Generator and Grid Control

- Generator Control: Enables comprehensive generator control; optimizes generator power control to achieve maximum electricity generation at any wind turbine speed. It also protects the generator gently—reducing mechanical stress through drive system vibration damping to extend equipment service life.

- Grid Control: Relies on advanced active and reactive power control to ensure compliance with grid codes at all times, easily adapting to different grid operating conditions.

6.2 Fault Response and Test Support

- Equipped with a dynamic braking chopper, it enables low-voltage ride-through (LVRT) and smooth wind turbine shutdown, ensuring equipment safety even in the event of a complete grid power outage.

- Features both high-voltage ride-through (HVRT) and LVRT capabilities, allowing the wind turbine to remain connected to the grid during significant grid disturbances, minimizing the impact of grid faults on wind power generation.

- Supports factory testing, back-to-back testing, and precise rotor positioning, simplifying testing and service tasks and facilitating equipment maintenance and commissioning.

6.3 Start-Up and Operational Adaptability

- Pre-Charging Soft Start: Achieves zero-current, flicker-free, and surge-free grid synchronization, ensuring stable and safe equipment start-up.

- Flexible Harmonic Spectrum Design: Easily adapts to different grid systems, avoiding harmonic resonance issues.

- Islanded Mode Operation: Ensures that when the wind turbine is not connected to the grid, it can supply power to the turbine’s auxiliary systems, guaranteeing their normal operation.

The exceptional performance of the PCS6000 is supported by advanced control technology. It is equipped with ABB’s high-performance AC 800PEC controller, which enables fast and efficient control of the generator-side converter and grid-side converter. This not only maximizes electricity generation and minimizes mechanical stress on the drive system but also lays a solid foundation for compliance with grid codes and ride-through capabilities.

Full-speed generator testing enables efficient testing of wind turbine components, while precise rotor positioning facilitates installation and allows for safe and convenient wind turbine maintenance.

7. High Reliability and Availability

The PCS6000 excels in terms of reliability and availability:

- Its simplified design uses fewer components with no parallel-connected devices, which not only improves reliability but also further reduces floor space.

- Long-lasting components significantly extend the component replacement cycle, lowering the converter’s lifecycle cost.

- Maintenance-friendly design provides easy access to all components, effectively reducing maintenance costs and shortening maintenance time.

- Fuse-free design, when combined with remote service tools, enhances converter reliability, availability, and performance—reducing downtime and LCOE. It also eliminates the need for on-site fuse replacement during disturbances, enabling remote restart after fault clearance.

- Filter-free design further improves equipment reliability and efficiency at higher power ratings.

For large-scale wind turbines, the PCS6000’s medium-voltage technology significantly reduces current to enhance efficiency; fewer components improve reliability; and its compact size, easy wiring, and quick installation effectively lower Capital Expenditure (CAPEX).

With its balanced converter design and use of high-quality components, the PCS6000 has become an industry benchmark for long service life and reliable operation. It is a sustainable, efficient, and economical choice, ensuring optimal equipment performance, grid stability, and fault-free operation.

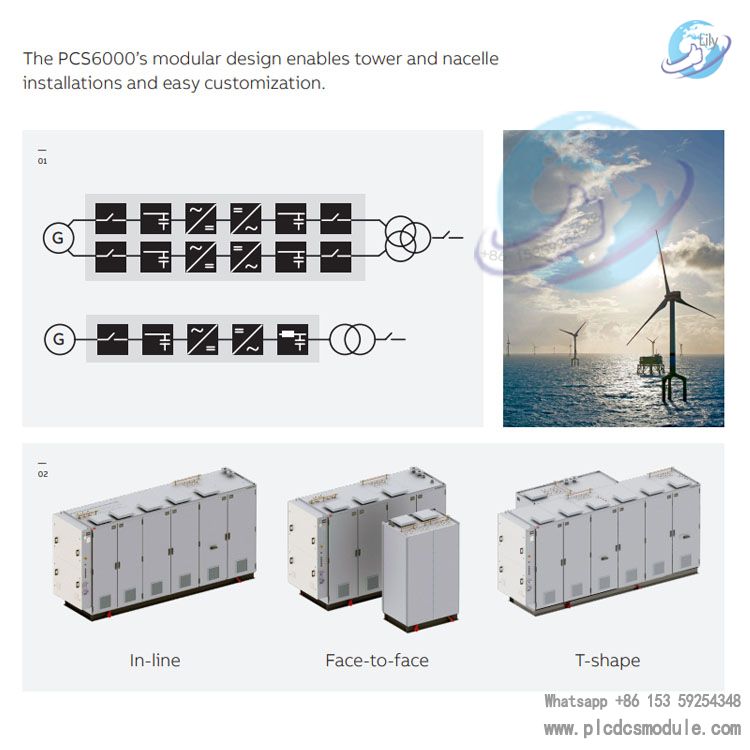

8. Modular Design and Flexibility

The modular design of the PCS6000 is a key highlight, offering high flexibility for equipment installation and customization:

- Standardized modules facilitate combination, enabling customized solutions for users with a maximum power capacity of 12MW to meet the needs of projects with different power requirements.

- The modular design allows users to flexibly arrange converter modules even on a single platform—supporting horizontal, face-to-face, or T-type layouts to adapt to different installation spaces and scenarios.

- This design makes the PCS6000 suitable for installation in compact spaces; it can be installed in towers, nacelles, or independent enclosures outside wind turbines according to actual needs. Installing it in the tower also reduces nacelle weight and simplifies maintenance, further enhancing equipment usability and overall operational efficiency.

9. ABB Wind Turbine Drivetrain System

ABB provides optimized components for wind turbine drivetrain systems, including generators and converters, which operate in synchronization to ensure efficient and stable performance of the entire drivetrain system.

ABB’s drivetrain system experts offer professional support to wind turbine manufacturers in the design and selection of drivetrain system components, while also providing strong assistance in the grid code certification process to facilitate smooth project progression.

9.1 Generators

Over the past 30 years, ABB has supplied more than 35,000 generators to major global wind turbine customers, covering the full range of wind turbine generators and supporting various drivetrain system concepts. Since the 1990s, ABB has maintained a leading position in permanent magnet generator (PMG) technology.

ABB’s generators have a standard power range of 100kW to 8MW, with a maximum power capacity of up to 20MW (15kV), meeting the needs of wind turbines of different scales. Specifically designed for harsh operating environments, these generators feature a high-performance Class F insulation system and rigid formed coil windings to ensure long service life, while also boasting high overload capacity for stable operation even under the frequently changing loads common in wind turbines. The bearing structure is also carefully designed to ensure reliable operation and a long service cycle.

9.2 Comprehensive Testing

To ensure the reliability of drivetrain system components, ABB conducts comprehensive testing on relevant equipment. At ABB’s testing facilities, equipment undergoes thorough testing and simulation to fully meet quality standards and customer requirements. Additionally, ABB can test the entire drivetrain system to verify its performance and compliance with grid codes, simplifying the wind turbine certification process and reducing on-site testing costs.

Wind turbine converters play a core role in ensuring wind turbines comply with grid codes. The PCS6000 undergoes ride-through and power quality testing to ensure it meets grid code requirements. Meanwhile, through comprehensive real-time simulation of typical grid disturbances, ABB verifies the PCS6000’s ability to withstand grid disturbances, ensuring compliance with all standards, further simplifying wind turbine certification, and reducing on-site testing costs.

Product Data Sheet

| Category | Details |

|---|---|

| Converter Model | PCS6000 Wind Power |

| Converter Type | 3-level, 4-quadrant, VSI-NPC (Voltage Source Inverter - Neutral Point Clamped), fuse-free design |

| Power Range | Up to 12 MW |

| Rated Voltage | 3.3 kV, 4.16 kV |

| Semiconductor Type | IGCT (Integrated Gate-Commutated Thyristor) |

| Capacitors | Self-healing and self-protected film capacitors |

| Supported Generators | High-, medium-, and low-speed permanent magnet generators, asynchronous induction generators, statically excited synchronous generators |

| Cooling - Converter Cooling | Closed-loop cooling unit, deionized water/ethylene glycol mixture coolant |

| Cooling - Coolant Inlet Temperature | Max. 45 °C (higher temperatures available on request) |

| Cooling - Pumps | 1 pump, or 2 pumps with automatic switching |

| Cooling - Heat Exchange | Water-air (external) / Water-water (external) |

| Cooling - Instruments/Sensors | Temperature, pressure, conductivity |

| Cooling - Deionization | Automatic deionization by resin |

| Cooling - Venting | Automatic control via vent valve |

| Cooling - Temperature Control | Control logic / motor-driven valve |

| Brake Chopper/Resistor - Chopper Semiconductor | IGCT |

| Brake Chopper/Resistor - Brake Resistor Capacity | 15 MJ / 30 MJ (other brake resistor capacities available on request) |

| Brake Chopper/Resistor - Brake Resistor Dimensions (LxWxH mm) | 1160 x 670 x 660 / 1160 x 670 x 1030 |

| Brake Chopper/Resistor - Brake Resistor Weight | ~ 200 kg / ~ 400 kg |

| Brake Chopper/Resistor - Brake Resistor Cooling | Ambient air |

| Control - Controller | ABB AC 800PEC |

| Control - Generator-Side Control | Pulse Width Modulation (PWM) |

| Control - Grid-Side Control | Optimized pulse pattern |

| Control - Fieldbus Interfaces | Profibus DP, Profinet IO, Modbus TCP, EtherCAT, CANopen |

| Control - Ethernet | Service and maintenance access via software tools installed on IPC Windows; VPN remote access ready |

| Control - Transient Recording | Circular buffer, high resolution |

| Control - Service IPC | Monitoring, data logger, remote access |

| Control - Operating Modes | Shutdown / Standby / Power Generation |

| Control - Generator-Side Setpoints | Power factor / reactive power |

| Control - Special Operating Modes | Positioning / Testing / Static Var Compensation (SVC) / Islanded Mode |

| Control - Local Control | Emergency stop |

| Control - Local Display | Power generation, grid-side disconnector closed, DC link switch closed/open, rotor locked |

| Electrical Interfaces - Generator-Side Connection | From top (Pfisterer P3) |

| Electrical Interfaces - Grid-Side Connection | From top (Pfisterer P3) |

| Electrical Interfaces - Brake Resistor Connection | From rear (Pfisterer P3) |

| Electrical Interfaces - Control Connections | From bottom (terminals inside control cabinet) |

| Enclosure - Structural Design | 1.5 mm carbon steel, edge-bent steel plates on a rigid base frame (MNS system), riveted and bolted |

| Enclosure - Protection Class | IP 54 |

| Enclosure - Corrosion Protection | Coating and/or galvanization |

| Enclosure - Door Lock System | Mechanical safety interlock for door opening when grounded |

| Enclosure - Condensation Protection | Protection with humidity sensor, temperature sensor, control logic, and space heater |

| Enclosure - Lifting | Bottom lifting with removable lifting eyes |

| Environmental Limits - Ambient Temperature | Transportation: -25 to +70 °C; Storage: -25 to +55 °C; Operation: -10 to +45 °C (other ambient temperatures available on request) |

| Environmental Limits - Altitude | 0 - 1000 m |

| Product Compliance - Product Marking | CE (compliant with 2014/35/EU, 2014/30/EU); DNV-GL (compliant with GL-IV-2:2012); CGC (compliant with CGC-R46022:2011) |

| Product Compliance - Quality Management System | ISO 9001:2008 |

| Product Compliance - Environmental Management System | ISO 14001:2004 |

| Product Compliance - Occupational Health and Safety Management System | OHSAS 18001:2007 |

Configuration Examples

| Power Rating (Depends on Generator Frequency, Heat Dissipation, and Grid Code Requirements) | 4 MW / 5 MVA | 7 MW / 8.5 MVA | 10 MW / 12 MVA | 12 MW / 14.5 MVA (Redundant version available on request) |

|---|---|---|---|---|

| Generator Winding System | Single winding | Single winding | Single winding | Double winding |

| Generator Rated Voltage | 4.16 kV | 3.3 kV | 3.3 kV | 3.3 kV |

| Generator-Side Voltage Range | 0 to 4.3 kV | 0 to 3.4 kV | 0 to 3.4 kV | 0 to 3.4 kV |

| Grid-Side Voltage Range | 0 to 4.3 kV | 0 to 3.4 kV | 0 to 3.4 kV | 0 to 3.4 kV |

| Number of IGCTs | 12 + 12 | 12 + 12 | 12 + 24 | 24 + 24 |

| Generator-Side Rated Frequency Range | 0-120 Hz (other generator-side frequencies available on request) | 0-120 Hz (other generator-side frequencies available on request) | 0-120 Hz (other generator-side frequencies available on request) | 0-120 Hz (other generator-side frequencies available on request) |

| Grid-Side Frequency | 50 or 60 Hz | 50 or 60 Hz | 50 or 60 Hz | 50 or 60 Hz |

| Efficiency at Converter Rated Point | ~ 0.98 % | ~ 0.98 % | ~ 0.98 % | ~ 0.98 % |

| Generator-Side du/dt Filter | < 1.5 kV/μs | < 1.5 kV/μs | < 1.5 kV/μs | < 1.5 kV/μs |

| Grid-Side Filter | Sinusoidal filter | Sinusoidal filter | du/dt filter | du/dt filter |

| Horizontal Arrangement Dimensions (LxWxH mm) | 4560 x 1280 x 2460 | 4960 x 1280 x 2460 | 5160 x 1280 x 2460 | 5960 x 1280 x 2460 |

| T-Type Arrangement Dimensions (LxWxH mm) | On request | On request | 4360 x 2100 x 2460 | 5160 x 2100 x 2460 |

| Face-to-Face (2 Cabinets) Arrangement Dimensions (LxWxH mm) | 3350 x 1280 x 2450; 1250 x 1080 x 2450 | 3550 x 1280 x 2450; 1450 x 1080 x 2450 | On request | On request |

| Back-to-Back Arrangement Dimensions (LxWxH mm) | 3350 x 2280 x 2450 | 3550 x 2280 x 2450 | On request | On request |

| Weight | ~ 5100 kg | ~ 5300 kg | ~ 6200 kg | ~ 7300 kg |

| Coolant System Connection | DN80 from top | DN80 from top | DN80 from top | DN80 from top |

| Auxiliary Power Voltage | 3-phase, 400 V, 50 or 60 Hz | 3-phase, 400 V, 50 or 60 Hz | 3-phase, 400 V, 50 or 60 Hz | 3-phase, 400 V, 50 or 60 Hz |

| Auxiliary Power Consumption | ~ 6 kW | ~ 8 kW | ~ 8 kW | ~12 kW |

3005319639

3005319639