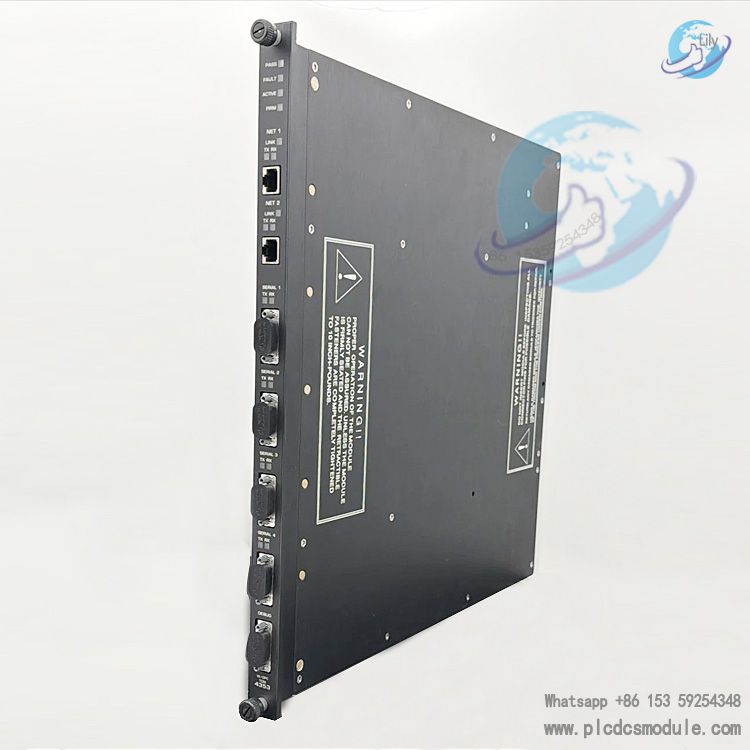

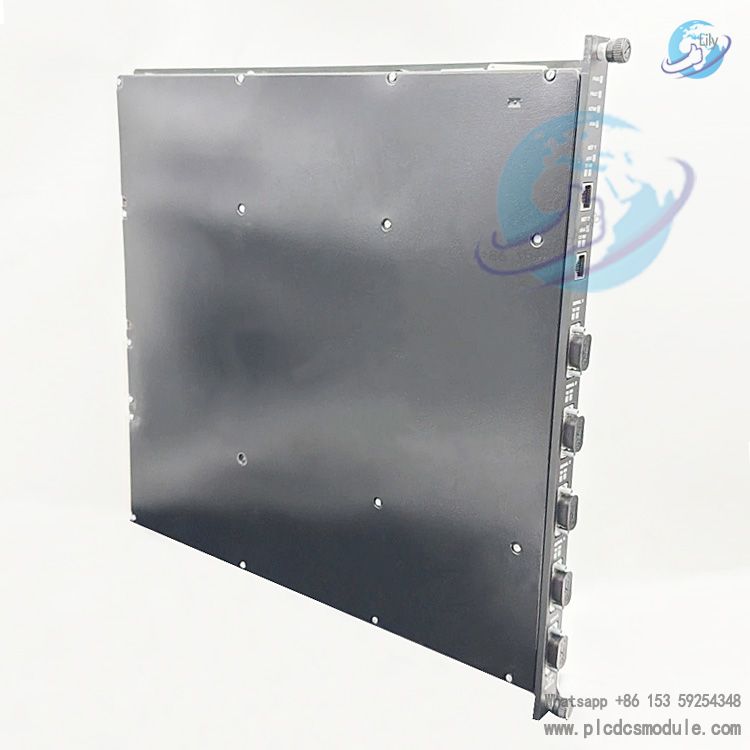

TRICONEX TCM 4353 COMMUNICATION MODULE 7400280-110 TCM4353

Product Overview

The TRICONEX TCM 4353 (part number 7400280 - 110) is a high-reliability communication module tailored for Triconex safety instrumented systems. It is widely used in harsh industrial environments such as oil and gas, chemicals, and power. It enables seamless connectivity and data transmission between the Triconex controller and various external devices and networks.

Technical Parameters

| Category | Key Specification Details |

| Communication Ports | 2 RJ-45 Ethernet ports (10/100Mbps, Net2 supports 100Mbps only); 4 DB-9 RS-232/RS-485 serial ports |

| Communication Speed | Ethernet: 10/100Mbps; Serial ports: Up to 115.2kbps |

| Supported Protocols | TCP/IP, Modbus (Master/Slave modes), SNTP, TriStation; Built-in OPC server |

| Power Requirement | 24VDC, 1.5A |

| Electrical Protection | 500VDC galvanic isolation |

| Operating Environment | Temperature: -40°C~70°C; Humidity: 5%~95%RH (non-condensing) |

| Anti-interference Capability | Vibration: 0.5g RMS (5-500Hz); Shock: 5g (22ms half-sine wave) |

| Physical Specifications | Dimensions: 233×178×89mm; Weight: Approximately 2.3kg |

Functional Features

application scenarios

1.Oil & Gas IndustryCovers upstream exploration, midstream transportation, and downstream refining. Connects ESD, F&G systems, and pipeline monitoring equipment, enabling reliable data transmission between field devices and central control for safe operation.

2.Chemical IndustryApplied in reactor control, material conveying, and HIPPS. Links safety instrument systems (SIS) and DCS, ensuring accurate transmission of critical process data to prevent accidents involving flammable/toxic media.

3.Power IndustrySuitable for thermal/nuclear power plants. Facilitates data interaction among boiler control, turbine regulation, and reactor safety systems, meeting strict SIL 3 safety communication requirements.

4.Pharmaceutical IndustryUsed in API synthesis, sterile production, and filling lines. Connects process monitors and quality control equipment, ensuring GMP compliance through real-time parameter transmission and data traceability.

5.Metallurgical & General ManufacturingAdapts to high-temperature/dusty metallurgical environments (blast furnaces, steel rolling) for equipment status communication. Integrates with PLC/HMI in automated lines to enable production data sharing and efficient scheduling.

3005319639

3005319639