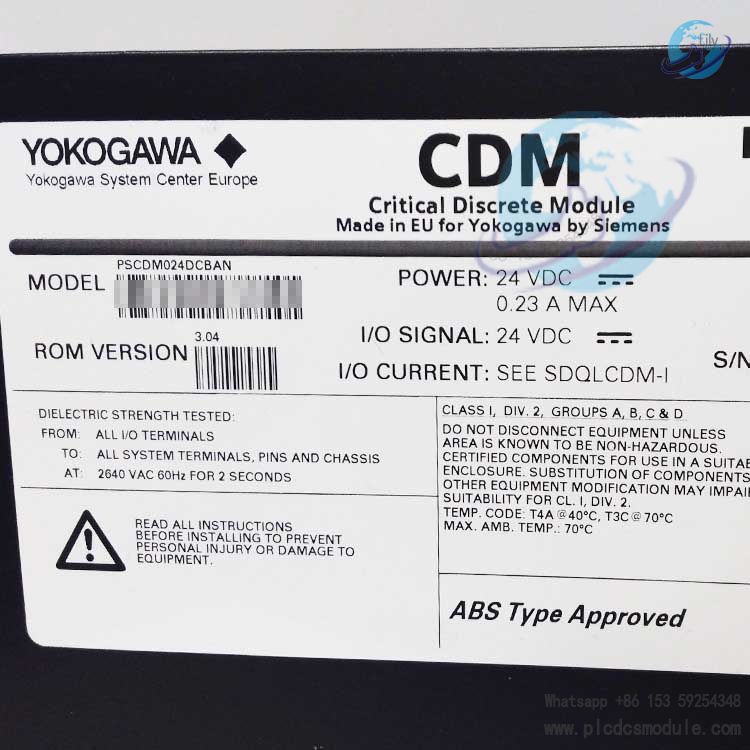

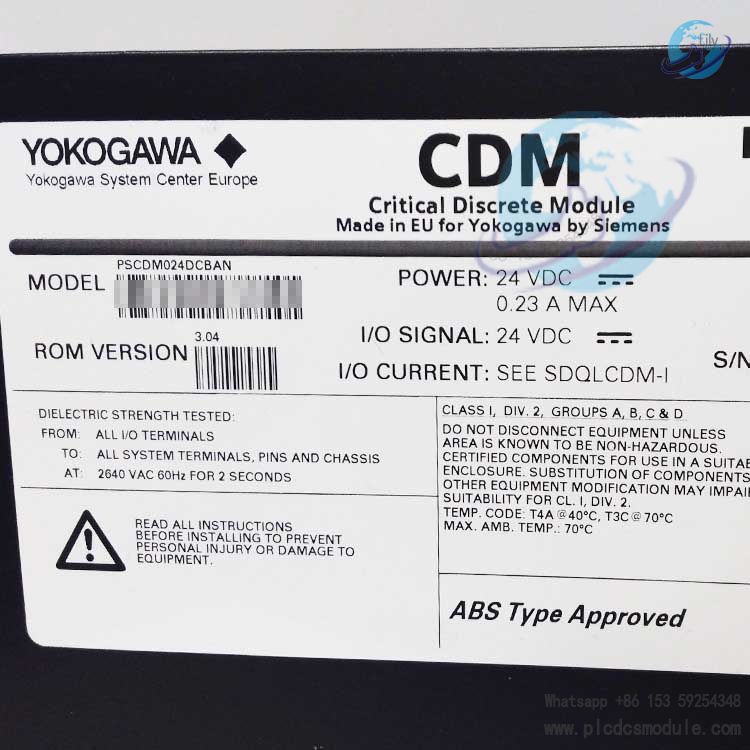

Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. The Yokogawa PSCDM024DCBAN A5E0024837106 is a high-performance servo control module belonging to Yokogawa Electric PSCDM series. It is compatible with Yokogawa distributed control systems (DCS) such as the FA-M3, and is specifically designed for high-precision, high-response servo motion control in industrial scenarios. This module enables precise closed-loop control over the position, speed, and torque of single-axis servo motors, and is widely used in automation production lines, semiconductor manufacturing, precision machine tools, robotics, and other fields requiring precision positioning and dynamic response. It features a modular design, multi-protocol compatibility, and high reliability.

Core Functions

Multi-mode Closed-loop ControlIt supports three basic modes: position control (pulse command/absolute position), speed control (analog signal/communication command), and torque control (current loop). Seamless mode switching can be achieved via parameter configuration, making it adaptable to diverse process requirements such as dispensing, mounting, and cutting.

High-precision Feedback and RegulationThe module is compatible with signals from incremental encoders (e.g., 17-bit) and absolute encoders. Combined with Yokogawa’s self-developed high-speed control algorithm, it delivers micron-level positioning accuracy and microsecond-level dynamic response. The position control accuracy can reach ±1 pulse equivalent, and the speed control accuracy is ≤±0.01% of the rated speed.

Flexible Command & I/O InteractionThree command input methods are supported: pulse train (CW/CCW), analog signal (±10V/4-20mA), and network communication (e.g., EtherNet/IP, Modbus TCP). It is configured with 8 channels of digital input (DI) for signal acquisition such as origin and limit signals, and 4 channels of digital output (DO) for status indication such as alarm and ready signals. It supports 24VDC dry contact/PNP input and output.

Comprehensive Fault Diagnosis and ProtectionIt is equipped with full-range fault detection functions including overcurrent, overvoltage, undervoltage, overheating, motor overload, and encoder abnormality, and supports fault code storage and alarm output. Built-in surge suppression and electrical isolation (2500VDC input-output-power triple isolation) complies with the IEC 61131-2 safety standard, reducing the risk of system malfunction.

Convenient Configuration and DebuggingIt is compatible with Yokogawa FA-M3 programming software, supporting parameter upload/download, online monitoring, trajectory simulation, and automatic gain control (AGC), which significantly shortens the commissioning cycle. Remote diagnosis and maintenance are available via the CPU port or Ethernet.

Technical Specifications

Core Advantages

High CompatibilityThe modular design enables seamless integration with the Yokogawa FA-M3 system and is compatible with third-party 24VDC servo motors, reducing the cost of system upgrades.

High ReliabilitySelected industrial-grade components support 24/7 continuous operation, with a mean time between failures (MTBF) of ≥100,000 hours, making it suitable for harsh industrial environments.

Low Total Cost of Ownership (TCO)Hot-swappable replacement is supported, with intuitive fault diagnosis for high maintenance efficiency. No additional programming is required for software configuration, which cuts down labor costs of commissioning and operation & maintenance.

Openness and ScalabilityIt supports mainstream industrial Ethernet protocols and can be connected to SCADA and MES systems, facilitating production data traceability and remote operation & maintenance, and is well-adapted to Industry 4.0 scenarios.

Application Scenarios

Precision ManufacturingIt is applied to semiconductor wafer cutting/handling equipment, PCB drilling machines, and precision dispensers, enabling micron-level positioning and trajectory following control.

Automated Production LinesIt supports multi-axis coordinated motion control for lithium battery electrode winding and 3C product assembly lines, improving production line efficiency and product consistency.

Intelligent EquipmentIt is used for joint control of collaborative robots and positioning & speed synchronization of automatic inspection equipment, meeting the requirements of flexible production.

Energy and Process IndustriesIn photovoltaic wafer cutting and optical fiber drawing equipment, it realizes precise coordinated control of tension and speed, ensuring product qualification rates.

Customers who purchased this product are also browsing the following products:

YOKOGAWA NFAI143-H00 analog input module

Yokogawa AIP830-111 S2 Operation Keyboard

YOKOGAWA PW301 Power Supply Module

Yokogawa CP451-10 S2 Processor Module

3005319639

3005319639