Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. The

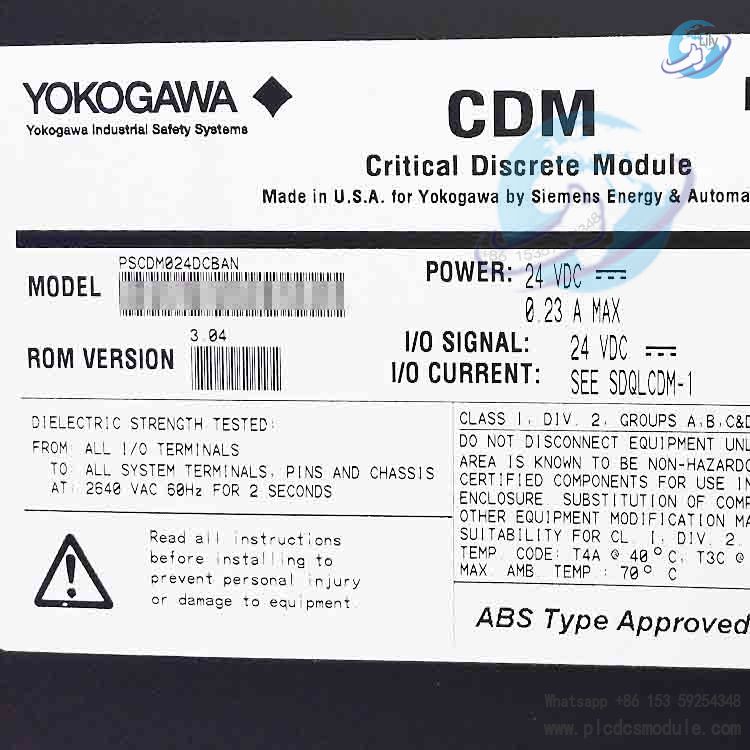

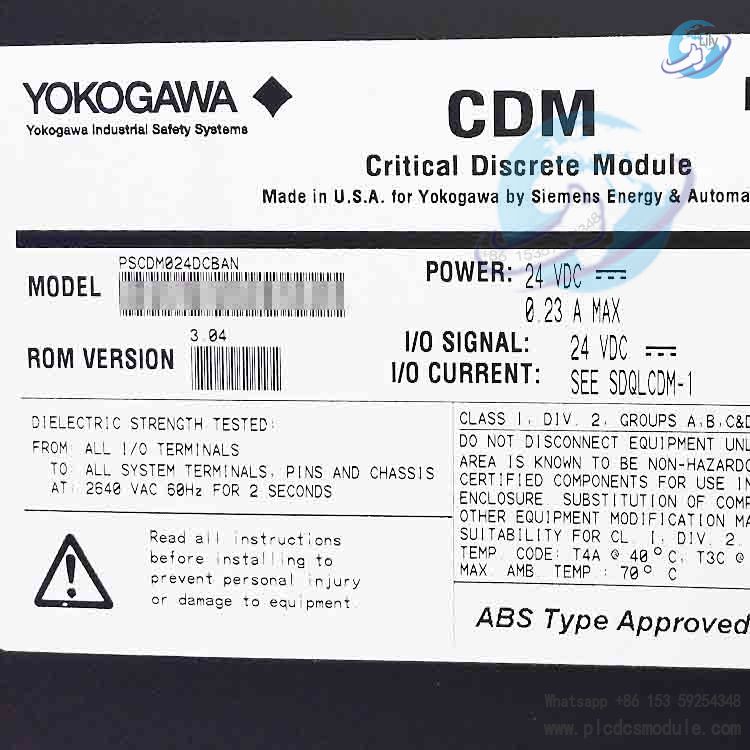

PSCDM024DCBAN 16800-5415 is a compact, high-precision

servo control module launched by Yokogawa Electric. As a member of the company PSC series industrial automation control products, it is designed for 24VDC power supply scenarios and targets industrial applications requiring precision motion control.

This module offers three core control modes: position, speed and torque, and features 24-bit high-resolution feedback and microsecond-level dynamic response. It is compliant with the IEC 61131-3 programming standard and supports mainstream communication protocols including Ethernet and RS-232, enabling seamless integration into various automation systems. It delivers reliable solutions for high-precision positioning and synchronous control in sectors such as machinery manufacturing, semiconductor equipment and robotics. Meanwhile, its modular design and comprehensive self-diagnostic functions ensure both system expansion flexibility and operational stability.

Core Functions

Multi-mode Precision ControlIt supports three control modes: position control (pulse frequency: 50kHz–2MHz), speed control and torque control. Mode switching can be quickly achieved via parameter configuration, adapting to the motion requirements of different processes such as dispensing, assembly and cutting, and satisfying diverse scenarios ranging from high-speed positioning to constant torque output.

High-resolution Feedback & High-speed ResponseBuilt-in with a 24-bit encoder signal processing unit, it achieves nanometer-level positioning accuracy and microsecond-level dynamic response speed. It can rapidly suppress load disturbances and ensure the precision and stability of motion trajectories.

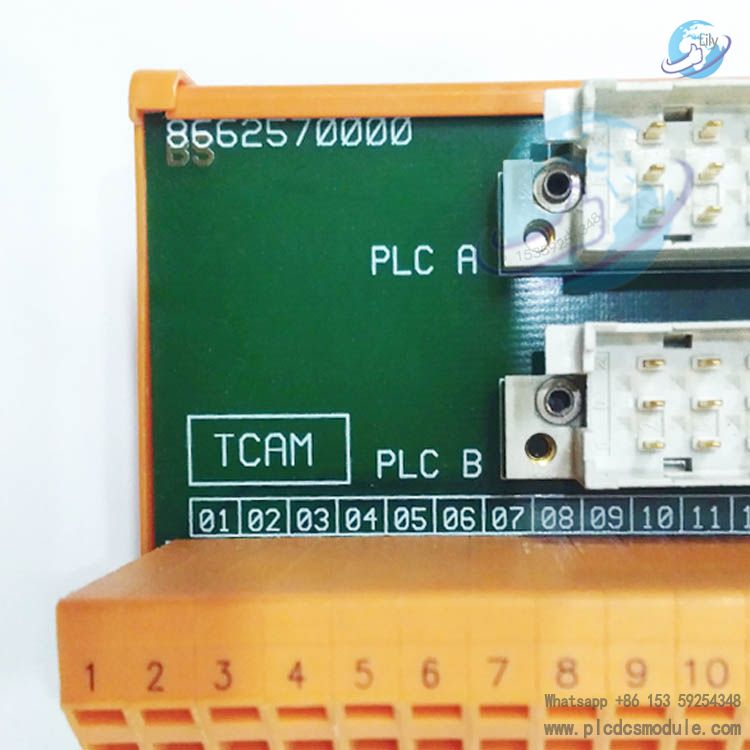

Flexible Communication & System IntegrationEquipped with Ethernet and RS-232 communication interfaces, it supports mainstream industrial protocols and enables real-time data interaction with PLCs, HMIs and upper-level control systems. It also supports remote parameter configuration, status monitoring and program downloading, facilitating the construction of distributed control networks.

Comprehensive Fault Diagnosis & ProtectionIt features multiple fault detection functions including overcurrent, overvoltage, overheating and encoder abnormality. It can record fault codes in real time and trigger alarm outputs, and supports redundant configuration to reduce system downtime risks and improve equipment operational reliability.

Easy Programming & DebuggingCompatible with the IEC 61131-3 standard programming environment, it provides a graphical parameter setting interface and supports offline simulation and online debugging. This allows for rapid system configuration and performance optimization, shortening the project commissioning cycle.

Core Advantages

Balanced High Precision and High ResponsivenessBoasting 24-bit high resolution combined with microsecond-level response, the module addresses the core requirements of accurate positioning and fast response in precision manufacturing. Compared with similar products, it improves control accuracy by approximately 15%–20% in scenarios involving high-speed start-stop operations and sudden load changes.

Modular Design for Easy MaintenanceAdopting a plug-and-play modular structure, it allows for quick replacement and expansion. It is compatible with other I/O modules of Yokogawa PSC series, enabling flexible scaling of control axes according to production capacity requirements and reducing the costs of later-stage maintenance and upgrades.

High Reliability for Industrial EnvironmentsEquipped with multiple fault protection mechanisms and a redundant design, the module is suitable for the complex electromagnetic environments of industrial sites. It features a wide operating temperature and humidity range, ensuring stable operation under harsh conditions such as dust and vibration, with a mean time between failures (MTBF) of over 100,000 hours.

Low-Cost and Efficient IntegrationIt can be directly connected to existing automation systems without the need for additional dedicated control units, simplifying the hardware architecture. Meanwhile, its user-friendly programming and debugging functions reduce on-site commissioning workload, lowering the overall project implementation costs.

Application Scenarios

Machinery ManufacturingIt is used for precision conveying and positioning in automated production lines, spindle synchronization control in CNC machine tools, and precise adjustment of slider movement in stamping equipment, improving machining accuracy and production efficiency.

Semiconductor and Electronic ManufacturingIt is suitable for high-precision positioning control of wafer handling robots and chip packaging equipment, meeting the requirements of micron-level assembly and testing, and ensuring product yield.

RoboticsIt provides servo drive control for joint movements of collaborative robots and SCARA robots, achieving precise synchronization of multi-axis coordinated motion, and adapting to flexible operation scenarios such as assembly and sorting.

Specialized Automation EquipmentFor equipment such as dispensers, labeling machines and wire winding machines, it realizes constant-pressure dispensing through torque control and ensures labeling accuracy through position control, adapting to the flexible production needs of small batches and multiple varieties.

Customers who purchased this product are also browsing the following products:

YOKOGAWA NFAI143-H00 analog input module

Yokogawa AIP830-111 S2 Operation Keyboard

YOKOGAWA PW301 Power Supply Module

Yokogawa CP451-10 S2 Processor Module

3005319639

3005319639