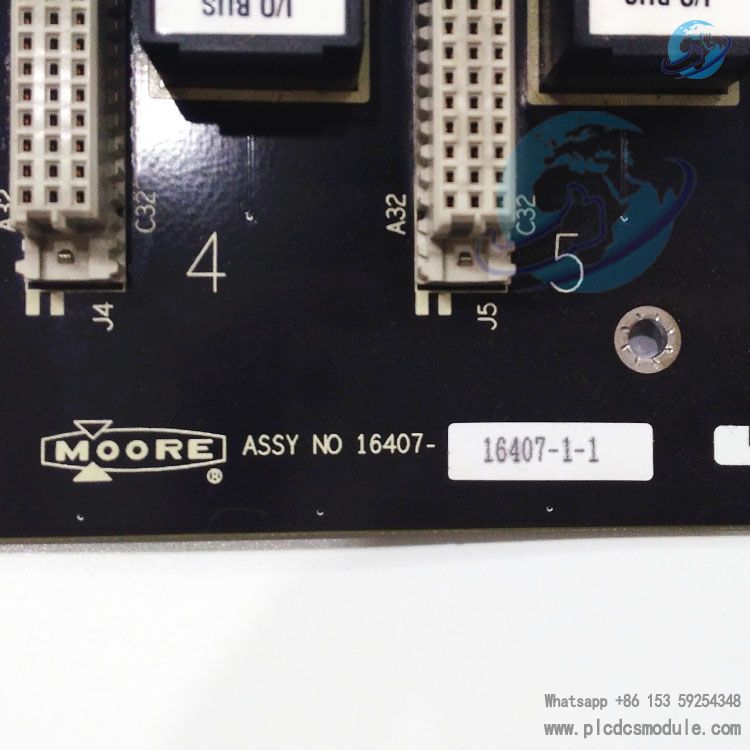

Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. 16407-1-1 I/O Chassis Rack Backplane is an I/O chassis rack backplane launched by Moore Company, designed for industrial automation control systems. As a core hardware component connecting I/O modules and the control system host, it plays a critical role in signal transmission, power distribution, and inter-module communication. It is commonly deployed in industrial scenarios with extremely high requirements for stability and reliability, such as gas turbine control. This backplane is compatible with specific series of I/O modules, providing the system with a stable hardware foundation and flexible scalability.

Core Functions

Signal Transmission & CommunicationThe backplane incorporates a dedicated bus communication circuit, enabling data exchange between the host and individual I/O modules. It ensures stable transmission of both analog signals (e.g., 4-20mA current signals, 0-10V voltage signals) and digital signals, and supports parallel communication across multiple modules. This guarantees real-time performance and accuracy of data transmission, meeting the requirements for rapid response in industrial control scenarios.

Power DistributionEquipped with standardized power distribution interfaces, the backplane can stably allocate externally input power (typically 24VDC industrial power supply) to all I/O modules installed in the chassis. It is also integrated with power protection circuits – including overcurrent and overvoltage protection – which prevent module damage caused by power anomalies and ensure power supply safety for the entire I/O system.

Module Positioning & SecuringIt features standard module slots that accurately position I/O modules for reliable connection with the backplane. Designed in compliance with industrial standards, these slots support hot-swapping (for certain compatible modules). This allows users to replace and maintain modules during system operation, minimizing system downtime.

System Expansion & CompatibilityThe backplane supports expanded installation of multiple I/O modules, allowing users to flexibly configure different types and quantities of I/O modules (such as digital input/output modules and analog input/output modules) based on actual control requirements. Fully compatible with relevant Moore-series I/O modules, it offers strong adaptability and provides hardware support for flexible system construction.

Technical Specifications

Model: 16407-1-1Type: I/O Chassis Rack BackplaneCompatible Modules: Specific I/O modules of Moore seriesNumber of Slots: 16 slots (typical), supporting installation of 16 I/O modulesPower Input: 24VDC (typical value, operating range: 18–32VDC)Signal Transmission Types: Analog signals (4–20mA, 0–10V, etc.) and digital signalsCommunication Protocol: Compatible with the dedicated communication protocol of Moore series control systemsMounting Method: Standard rack mounting, compatible with 35mm standard DIN railOperating Temperature: 0–60℃ (industrial standard operating temperature range)Relative Humidity: 5%–95% (non-condensing)Protection Rating: IP20 (suitable for cabinet mounting)

Installation & Maintenance Guidelines

Pre-installation Preparation

Prior to installation, inspect the backplane for any physical damage and ensure that all slots are clean and free of foreign objects. Prepare compatible I/O modules, power cables, communication cables and installation tools. Verify that the installation environment meets the product’s operating conditions, such as temperature and humidity requirements.

Installation Procedures

First, mount the backplane securely onto the 35mm standard rail of a rack or control cabinet.

Then, insert I/O modules into the backplane slots one by one in accordance with the module markings until each module clicks firmly into place, ensuring reliable electrical contact between the modules and the backplane.

Next, connect the power cables, confirm correct power polarity and then power on the system.

Finally, connect the communication cables to establish communication between the backplane and the host controller.

Maintenance Precautions

Periodically inspect the connection status of the backplane, including module-to-slot connections and cable connections, to prevent signal transmission abnormalities caused by loose connections.

Keep the backplane and its surrounding environment clean to avoid dust accumulation, which may compromise heat dissipation and electrical performance.

In case of module communication failures or power supply anomalies, first inspect the backplane power supply and communication interfaces, then troubleshoot the functionality of the modules. Replace faulty modules or the backplane if necessary.

Application Scenarios

The Moore 16407-1-1 I/O Chassis Rack Backplane is widely used in the field of industrial automation, including petrochemicals, power generation, metallurgy and manufacturing industries. As a mounting and connection carrier for I/O modules in Distributed Control Systems (DCS) and Programmable Logic Controller (PLC) systems, it is responsible for field signal acquisition and control command output. It ensures stable operation and precise control of industrial production processes, and is particularly suited for complex industrial control scenarios with high requirements for system reliability and scalability.

Customers who purchased this product are also browsing the following products:

Siemens 6DD2920-0AJ0460 Receiver Module

Siemens 6SN1118-0DH22-0AA1 Simodrive Board

SIEMENS 6ES7322-8BH10-0AB0 Digital Output Module

SIEMENS 6DD2920-0AN1 control module

3005319639

3005319639