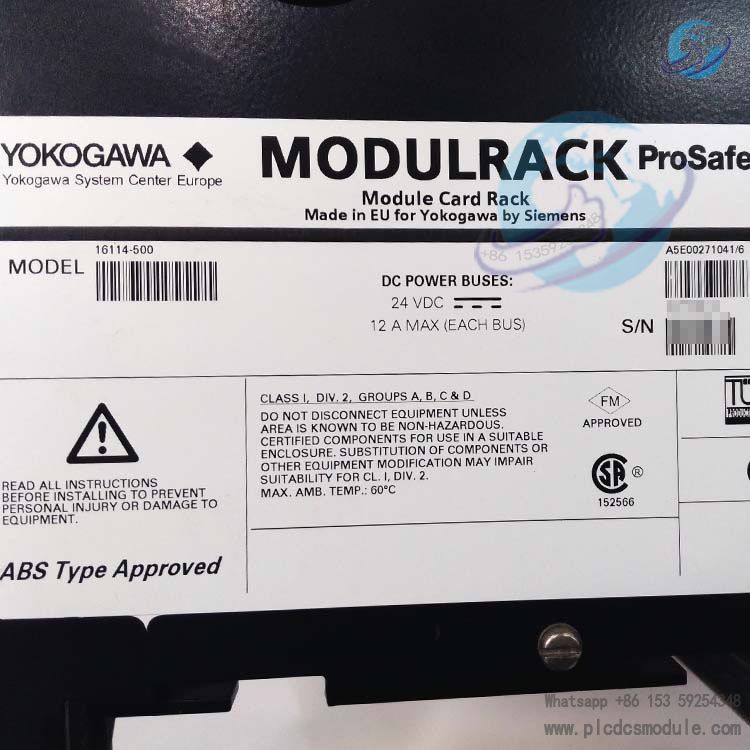

Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. The YOKOGAWA 16114-500 MODULRACK Module Card Rack (also commonly referred to as Siemens Moore 16114-500) is a modular card rack designed for industrial automation control systems. It is mainly applicable to Yokogawa industrial safety systems, Siemens Quadlog, ProSafe-PLC and related equipment from Moore Products. It provides a stable mounting carrier, reliable power distribution and signal transmission channels for various control modules and I/O modules. Boasting high compatibility, strong stability and easy maintainability, it can meet the requirements of harsh industrial field operating environments and ensure the efficient, safe and continuous operation of control systems. Its derivative models include 16114-500/4 and 16114-500/6, which are suitable for module configuration requirements in different application scenarios.

Core Parameters

Power Supply Parameters: The DC power bus is 24VDC, with a maximum current of up to 12A. It supports redundant power supply configuration and is equipped with reverse polarity protection, which ensures stable power supply and is compatible with common industrial power supply environments.

Module Compatibility: It is compatible with a variety of I/O modules and control modules of Yokogawa and Siemens Moore series, such as PSCCM24AAN and PSCDM024DCBAN. Different derivative models can meet the installation requirements of different quantities of modules.

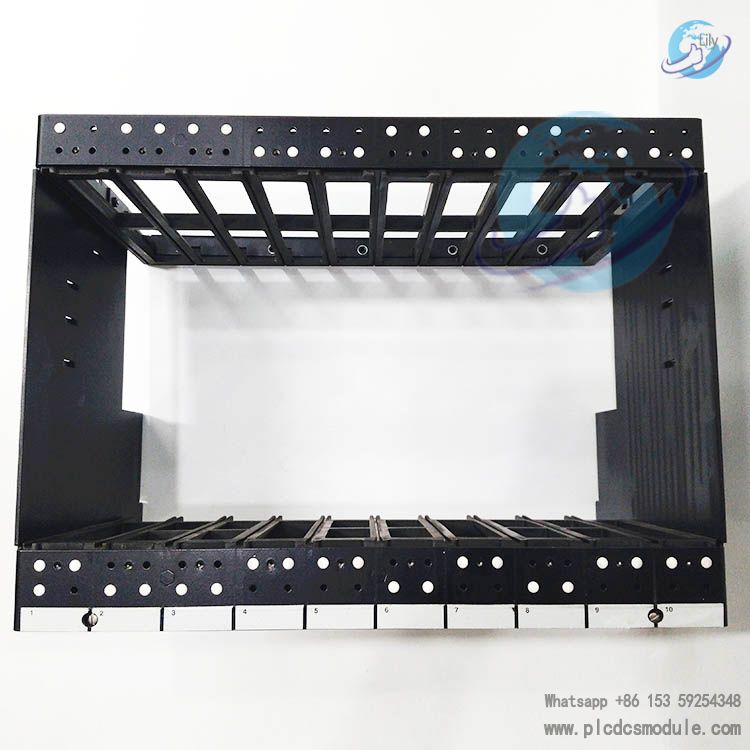

Mechanical Specifications: It adopts a standard 19-inch rack design, suitable for installation in industrial control cabinets. Featuring a robust structure, it has excellent vibration resistance and shock resistance performance. It supports flexible mounting methods including the common DIN rail mounting for industrial applications.

Environmental Adaptability: The typical operating temperature range is -20℃ to +70℃, enabling stable operation in harsh industrial environments. Its protection rating complies with industrial standards, which can resist the impact of dust, moisture and other factors on the equipment.

Structure & Functions

Modular DesignIt adopts a modular architecture, allowing flexible integration with modules of different functions, such as analog input/output modules, digital input/output modules, and communication modules. This facilitates system configuration according to actual control requirements, and also simplifies module replacement and upgrading, thereby reducing maintenance costs.

Power Distribution FunctionEquipped with a built-in 24VDC power bus, it can provide stable power supply to all modules installed on the rack. The maximum current output of 12A is sufficient to meet the power demands of multiple modules operating simultaneously. The redundant power supply design effectively prevents total system breakdown caused by a single power supply failure, enhancing the operational reliability of the system.

Signal Transmission & IsolationThe rack is integrated with high-performance internal signal transmission channels, which ensure fast and accurate signal transmission between modules. Certain models are also built with a signal isolation function, which can effectively reduce the impact of electromagnetic interference from industrial sites on signals and improve the precision of data acquisition and control.

Diagnostic & Monitoring CapabilitiesThe rack enables fault diagnosis and status monitoring functions for certain compatible modules. It can promptly detect issues such as module malfunctions and power supply anomalies, and feed the information back to the control system through relevant interfaces. This allows operators to quickly locate and resolve faults, shortening system downtime.

Application Scenarios

Petrochemical IndustryIn petrochemical production units, it can be used to install modules related to process control and safety interlocking. It enables real-time acquisition and control of process parameters such as temperature, pressure and flow rate, ensuring the safe and stable operation of production processes.

Power IndustrySuitable for control systems in power plants, it is designed to mount modules that monitor the operating status of power generation equipment, such as temperature and vibration monitoring modules for generators. It helps achieve automated control and safety management of power production.

Manufacturing IndustryServing as a mounting carrier for control cores in automated production lines of factories such as automobile manufacturing and electronics manufacturing, it can be integrated with various I/O modules to realize precise control of production equipment, improving production efficiency and product quality.

Metallurgical IndustryApplied in the control systems of equipment such as blast furnaces and rolling mills in metallurgical enterprises, it is adapted to harsh environments with high temperature and heavy dust. Relevant control modules can be installed on it to realize automatic adjustment of metallurgical processes, ensuring the continuity and stability of production.

Customers who purchased this product are also browsing the following products:

YOKOGAWA NFAI143-H00 analog input module

Yokogawa AIP830-111 S2 Operation Keyboard

YOKOGAWA PSCCM22AAN 16418-5312 | Critical Control Module

YOKOGAWA PSCAMAAN A5E0023936304 CRITICAL ANALOG MODULE

3005319639

3005319639