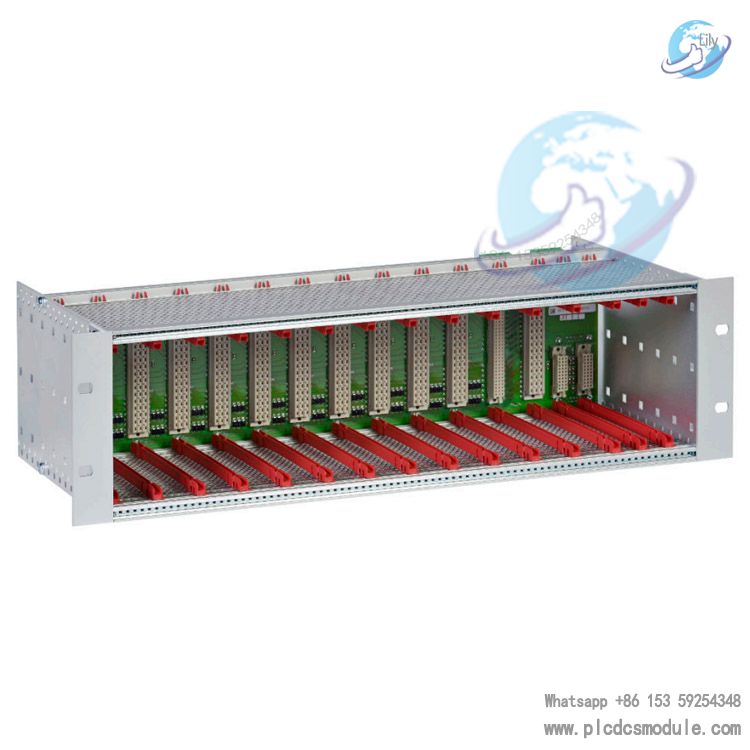

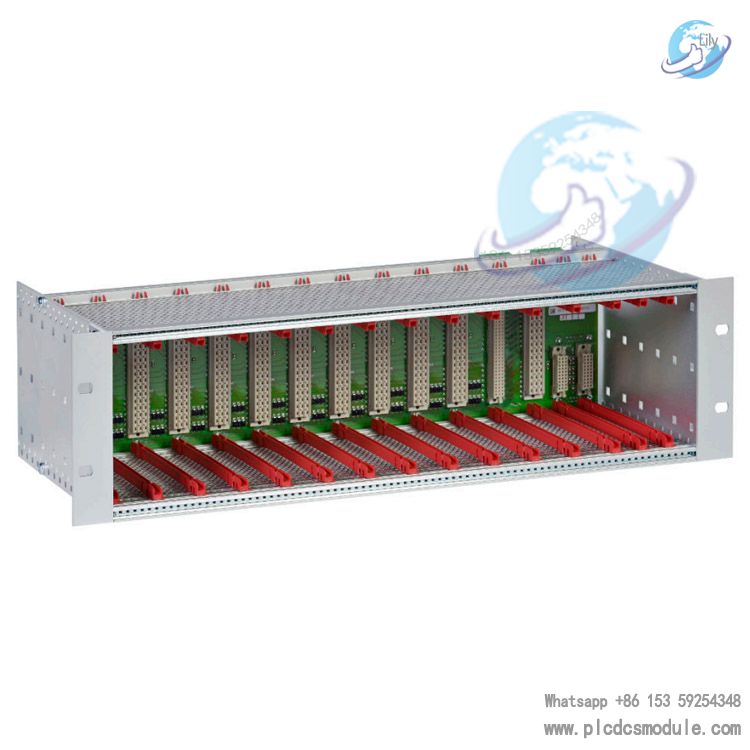

Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. The A6500-RR Redundant Relay Rack is a core component of Emerson AMS 6500 ATG Machinery Protection System, specially designed for the safety monitoring and redundant control of critical equipment. Adopting the 19-inch standard specification with a width of 84HP and a height of 3RU, this rack enables flexible integration of a variety of functional cards including protection cards, redundant relay cards and communication cards. It also features expandability and can form a 6RU system by adding a second rack, meeting the equipment protection requirements of different scales. Its design complies with a number of international standards, and balances the stability of signal connection, environmental adaptability and safety for use in hazardous areas. It is widely applied in industrial scenarios requiring high-reliability monitoring, such as the protection systems for critical assets including turbomachinery and heavy-duty equipment.

Download

Core Configuration and Expandability

1. Card Slot Configuration

The slot layout of the A6500-RR rack is optimized to support protection, relay control and communication functions simultaneously, with key modules designed with redundancy to enhance system reliability. The specific configuration is as follows:Protection Card Slots: 9 slots in total (6HP per slot), compatible with two types of core protection cards – the 2-channel A6500-UM Universal Measurement Card and the 4-channel A6500-TP Temperature Process Card. Each protection card slot is equipped with 4 eight-pole screw terminal connectors, supporting the access of various sensor signals including eddy current sensors (for vibration and displacement monitoring), piezoelectric sensors (for shock and acceleration monitoring), seismic sensors (for low-frequency vibration monitoring) and RTDs (Resistance Temperature Detectors, for temperature monitoring). It also enables connection of binary input/output, current output and pulse output signals. The number of measurement channels and specific functions are determined by the type of actually installed cards.Relay Card Slots: 2 redundant slots (10HP per slot) for installing A6500-RC Redundant Relay Cards. The backplane is provided with 12 shared digital input interfaces with signal connection via screw terminal connectors, ensuring redundant backup of relay control functions and avoiding control failure caused by single card malfunctions.Communication Card Slots: 2 redundant slots (4HP per slot) for installing A6500-CC Communication Cards, supporting a redundant communication architecture. When the system is expanded to 6RU (with a second rack added), no additional communication cards are required, and the communication card of the first rack can be directly reused to realize unified communication management of the dual racks.

2. System Expandability

If a single rack cannot meet the monitoring requirements, the system can be expanded to a 6RU configuration by adding a second A6500-RR rack. The expanded system still shares the communication card (A6500-CC) of the first rack without the need for additional communication modules, which reduces expansion costs while ensuring the consistency and stability of system communication.

Hardware Interfaces and Signal Connection

The front and rear interface design of the A6500-RR rack balances practicality and safety, ensuring the reliability of signal transmission and the convenience of configuration:Rear Interfaces: Equipped with screw terminal connectors (for fixed connection of input/output signals to prevent loosening), D-Sub connectors (providing raw sensor signal output for easy debugging and signal traceability) and slide switches (for configuration of key signals and binary inputs, enabling parameter adjustment without card disassembly). The backplane digital input interfaces of the relay card slots also adopt screw terminal connection to improve the anti-interference capability of signals.Dedicated Connector Specifications: Different card slots are matched with different types of standard connectors to ensure interface compatibility and connection stability, as detailed below:Protection card slots: F48 female connector, compliant with IEC 60603-2Relay card slots: C96 female connector, F48 female connector, compliant with IEC 60603-2Communication card (A6500-CC): C30 female connector, compliant with IEC 60603-2Power terminals: 2.5 mm² pluggable screw terminalsI/O terminals: 1.5 mm² pluggable screw terminalsSUB-D connectors: Shielded SUB-D 9, locked with UNC 4-40 screws

Power Supply and Environmental Parameters

1. Power Supply Specifications

The A6500-RR adopts a redundant DC power supply design to ensure power supply stability, with the specific parameters as follows:

Rated voltage: +24 V DC (redundant power supply)

Voltage range: +19 ~ +32 V DC. In the event of a single power supply failure, the voltage shall comply with the SELV (Safety Extra-Low Voltage)/PELV (Protective Extra-Low Voltage) requirements specified in IEC 60204-1 or IEC 61131-2 standards.

Power consumption: Power consumption of slots (with cards installed) < 100 W; additional power consumption for external output supply < 150 W.

2. Environmental Adaptability

The rack features wide temperature tolerance, vibration resistance, shock resistance and other characteristics, and can adapt to the complex environment of industrial sites, with the specific parameters as follows:

Protection rating: IP20 (compliant with IEC 60529) when rack-mounted, IP00 when non-rack-mounted.

Anti-corrosion coating: HumiSeal 1B31 EPA coating, compliant with IPC-CC-830B and IPC-A 610 standards, with resistance to air contaminants (compliant with ISA-S71.04-1985 Grade G3 air contaminant standards).

Temperature range: Operating temperature (forced cooling) -20°C ~ +70°C (-4°F ~ 158°F); Operating temperature (non-forced cooling) -20°C ~ +55°C (-4°F ~ 131°F); Storage temperature -40°C ~ +85°C (-40°F ~ 185°F).

Humidity: 5% ~ 95% RH (non-condensing).

Vibration resistance: 0.15 mm (0.591 in) amplitude at 10 ~ 55 Hz, 20 m/s² acceleration at 55 ~ 150 Hz (compliant with IEC 60068-2-6).

Shock resistance: 150 m/s² acceleration, 4000 shocks per axis (compliant with IEC 60068-2-27).

Operating altitude: < 2000 m above sea level.

Weight: Approximately 2400 g (5.291 lbs, excluding packaging); Dimensions: 3RU/84HP (compliant with IEC 60297 standard).

Ordering Information and Accessories

1. Main Product Model

A6500-RR: A6500-RR Redundant Relay Rack, equipped with 9 protection card slots (for UM/TP cards), 2 relay card slots (for RC cards) and 2 communication card slots (for CC cards).

2. Recommended Accessories

- A6068: Redundant power supply with 100-220V AC input and 24V DC output

- MHM-6XXX-RC-CABLE: Rack connection cable, SUB-D interface, 9-pin, 1 meter in length

Core Product Advantages (Integrated with the AMS 6500 ATG System)

As an integral part of the Emerson AMS 6500 ATG Machinery Protection System, the collaborative advantages of the A6500-RR rack with the system are mainly reflected in the following aspects:

- Integrated Protection and Prediction: Combined with the embedded predictive tools of the AMS 6500 ATG System (e.g., PeakVue Technology for early bearing fault detection), it can identify faults during transient phases such as equipment start-up and shutdown, achieving both real-time protection and asset health prediction.

- Flexible Integration and Compatibility: It supports connection with existing DCS/PLC systems, historical databases or MHI systems via OPC UA and Modbus TCP/RTU protocols, and is compatible with a variety of traditional sensors, reducing the costs of system upgrading.

- High-Reliability Design: Configurations including redundant power supplies, redundant relay cards and redundant communication cards, together with wide environmental adaptability and hazardous area certifications, ensure continuous and stable operation in harsh industrial scenarios.

3005319639

3005319639