Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. The MVI56-PDPMV1 is a PROFIBUS DPV1 Master network interface module for the ControlLogix platform developed by ProSoft Technology. It enables communication between ControlLogix processors and PROFIBUS networks, supports master-slave mode data transmission, cyclic and acyclic communication, and is compatible with automation control requirements in various industrial scenarios.

Data Sheet

ProSoft MVI56-PDPMV1.pdf

ProSoft MVI56-PDPMV1.pdf

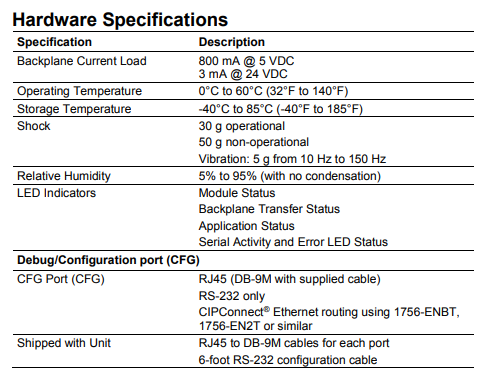

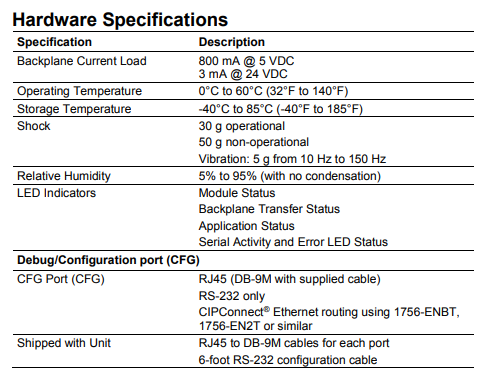

Specifications and Parameters

Electrical and Environmental Parameters

- Backplane Current Load: 800mA @ 5Vdc, 3mA @ 24Vdc.

- Operating Temperature: 0°C to 60°C (32°F to 140°F); Storage Temperature: -40°C to 85°C (-40°F to 185°F).

- Shock and Vibration Resistance: 30g operational shock, 50g non-operational shock; 5g vibration resistance at 10Hz to 150Hz.

- Humidity: 5% to 95% non-condensing.

Communication and Interface Parameters

- PROFIBUS Interface: Optically isolated RS-485, supporting up to 12Mbps baud rate, compatible with PROFIBUS DPV1 protocol, and supporting 125 slaves (with repeaters).

- Diagnostic Port: RJ45 interface (connected via DB9 adapter), supporting RS-232 communication and CIPconnect Ethernet routing.

- Backplane Communication: 32-bit/33MHz VMEbus, enabling flexible configuration of input/output data blocks.

Physical Characteristics

- Dimensions: Single-slot design, compatible with 1756 backplane.

Functional Features

Protocol and Communication Capabilities

- Supports PROFIBUS DPV1 protocol, including cyclic data transmission (1536 bytes input/output) and acyclic communication (Class 1/Class 2 Acyclic services).

- Enables sync/freeze commands, slave diagnostics, address setting, and alarm handling (DPV1).

Flexible Configuration Modes

- LEGACY Mode: Fixed I/O block sizes (250 words input, 248 words output), transferring status and mailbox data via regular I/O blocks.

- FLEX Mode: Variable I/O block sizes (12–250 words input, 5–248 words output), using MSG instructions for status and mailbox data transfer to optimize remote rack performance.

Software and Tool Support

- Comes with ProSoft Configuration Builder (PCB) software, supporting GSD file import, slave configuration, checksum calculation, and project backup.

- Compatible with FDT/DTM frameworks (e.g., PACTware), allowing network configuration and monitoring via comDTM.

Installation and Configuration Process

Hardware Installation

- Insert into a ControlLogix rack slot, powered via the backplane, and connect PROFIBUS cables (shielded twisted pair with matched terminator resistors).

Software Configuration

- Install PCB software and import GSD files to configure slave parameters (address, input/output sizes).

- Load sample ladder logic (.ACD or .L5X files) in RSLogix 5000, selecting LEGACY or FLEX mode based on firmware version.

- Set backplane I/O block sizes, Requested Packet Interval (RPI), and communication path (local/remote rack).

Diagnostics and Troubleshooting

LED Status Indicators

- OK LED: Green for normal operation, red for errors or configuration anomalies.

- PROFIBUS Status LEDs: COM STAT blinking green indicates partial slave communication, solid green for full slave communication, and red for bus errors.

Troubleshooting Tools

- View slave configuration lists (SLAVE CFG LIST), data transfer status (TRANSFER LIST), and diagnostic lists (SLAVE DIAG LIST) via PCB software's diagnostic window.

- Use MSG instructions to read mailbox responses or slave diagnostic data for fault 定位 (e.g., address conflicts, configuration mismatches).

Application Scenarios

- Manufacturing Industry: Connects PLC with distributed I/O, frequency converters, etc., enabling real-time data collection and control of production lines.

- Energy Sector: Monitors sensor data from wind turbines, generators, etc., supporting predictive maintenance.

- Automation System Integration: Acts as a master station to connect PROFIBUS slave networks, suitable for remote I/O expansion or multi-device collaborative control.

Compliance and Certifications

- Meets Class I, Division 2 explosion-proof standards, applicable to hazardous areas (Groups A, B, C, D).

- Supports ATEX certification, requiring installation in an IP54-rated enclosure with a certified backplane.

Notes

- The module's non-replaceable battery backs up the real-time clock, requiring 20 hours of charging for the first power-up and lasting approximately 21 days.

- For remote rack deployment, route via EtherNet/IP or ControlNet to ensure correct communication path configuration.

- FLEX mode is supported with firmware version 1.21 and above, requiring AOI functionality in RSLogix 5000 version 16 and above.

Customers who purchased this product are also browsing the following products:

prosoft 5302-MBP-MCM4 Modbus Master/Slave Gateway

prosoft 202-DFNT-MCM4 DP communication module

GE Hydran 201Ti Mark IV Essential DGA monitoring for transformers

IBA SM128V VMEbus Interface Board

Woodward BUM60-1224-54-B-001-VC-A0-0093-0013-G003-0000 3522-1004 Speed Controller

3005319639

3005319639