Company Overview

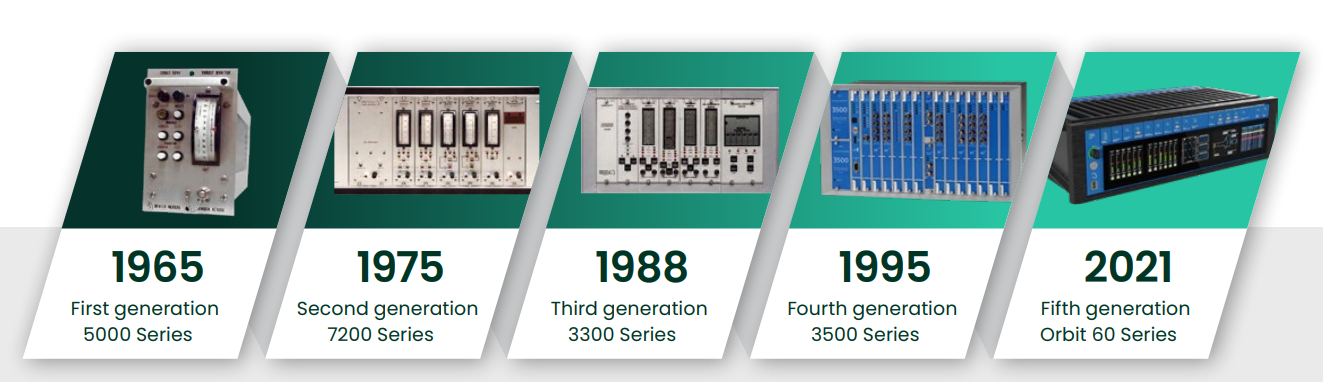

Bently Nevada is a part of the globally renowned Baker Hughes group. With over 60 years of dedicated efforts in the industrial field, it has amassed profound industry experience and leading professional technologies. As early as the beginning of the 1960s, Bently Nevada launched eddy current probes, pioneering the field of online mechanical condition monitoring and has since remained at the forefront of this field.

In 1995, Bently Nevada introduced the 3500 series products. This series of products has been developed based on the technological innovation achievements of approximately 50 years prior. Before that, the company successively launched the 5000 series from 1965 to 1998, the 1700 series from 1973 to 1998, the 9000 series from 1975 to 2003, and the 3300 series from 1988 to 2003. Each generation of products has been improved upon the previous generation, and the 3500 series has integrated the advantages of the previous generations, creating comprehensive and upgraded products and processes.

As an enterprise under Baker Hughes, Bently Nevada gives full play to its technological and experience advantages to provide high-quality products and services to customers around the world, assisting enterprises in managing and optimizing the performance of their assets. Its business widely covers multiple core industries such as oil and gas, power generation, chemical engineering, and manufacturing. Its products and services range from basic monitoring of on-site factory equipment to comprehensive optimization of enterprise-level management systems, providing all-round protection for the reliability of enterprise assets.

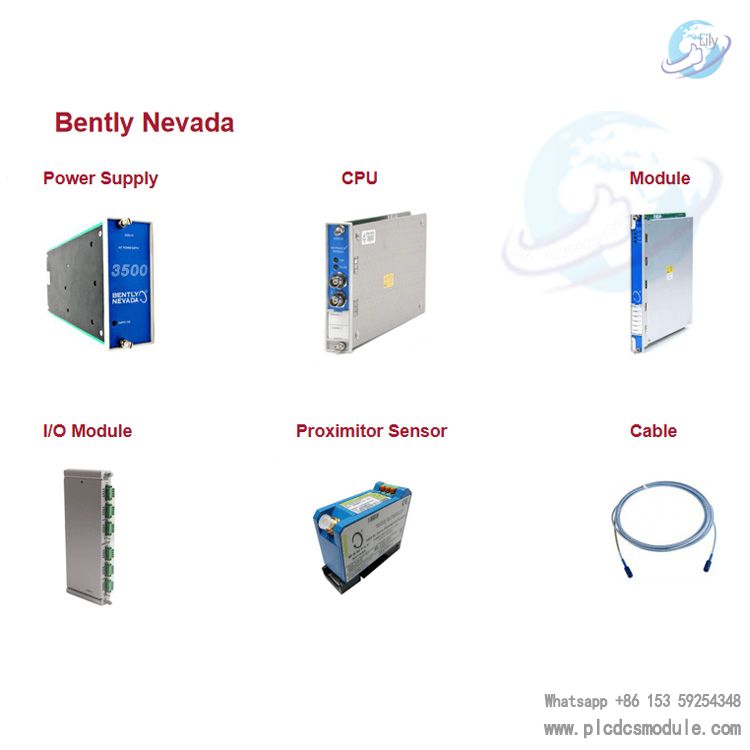

Core product system

monitoring system

(1).The Bently 3500 system, a renowned product of Bently Nevada in the United States, specializes in unit vibration monitoring and machine protection. It excels at monitoring the vibration of large rotating machinery, including turbines, hydraulic turbines, fans, compressors, turbo - expanders, motors, generators, exciters, gearboxes, pumps, and more. Widely applied in power plants, chemical plants, oil refineries, iron and steel mills, machinery factories, pump factories, fan factories, universities, scientific research units, as well as automation instrumentation complete - set enterprises, this system is highly versatile.

The Bently 3500 series machinery protection system, when paired with Bently (Bently Nevada) vibration sensor probes, offers an excellent measuring range. It can be used for various measurements such as shaft vibration, shaft displacement, key phase, speed, overspeed protection, eccentricity, thermal expansion, and differential expansion. It can accept vibration signals from the Bently 3300 eddy current sensor system (including Bently 3300XL sensor probes, extension cables, preamplifiers) and speed acceleration sensors like 330500, 330400, 9200, etc. Moreover, it fully complies with American Petroleum Institute 670 standards, ensuring high - quality performance and reliability. For more information about BENTLY NEVADA products please click here

data sheet

![]() 3500 Series Monitoring System EU Declaration of Conformity.pdf

3500 Series Monitoring System EU Declaration of Conformity.pdf

The bently 3500 security system consists of:

Frame: The physical support structure for the entire system, which is available in 19’ EIA rail mount, slotted panel mount, and wall plate mount to accommodate different installation environments and space requirements.

Power Modules: Provide stable power to the system, such as the 3500/15 AC Power Module, which has been designed to use the same main power supply and power input modules for all 85 to 264vac AC voltage input ranges.

Monitor Modules: These include the 3500/42m Vibration Monitor Module, the 3500/60 Temperature Monitor Module, the 3500/40m Displacement Monitor Module, etc., which accepts signals from different types of sensors to monitor various mechanical parameters.

Frame Interface Module: It is the main interface between the system and the configuration, display and condition monitoring software, and is used to realise the communication and data interaction between the system and external devices or software.

Communication Gateway Modules: such as the 3500/92 Communication Gateway Module, which enables the system to communicate with external devices such as plant control computers over Ethernet, facilitating data transfer and sharing.

Relay Module: 3500/32m, 3500/33m, etc. It can be used to make logical judgement and control output according to the monitoring results to achieve the functions of alarm and shutdown.

Keyer Module: such as 3500/25 Keyer Module, which provides keying reference signals for the Monitor Module to determine the phase information of rotating machines.

KEY FEATURES:

Continuous, online monitoring of rotating machinery

Wide range of measurement parameters

Fault detection and diagnostics

Machinery protection

Asset condition monitoring

Scalable and flexible

BENEFITS:

Reduced downtime: The systems can help to prevent unplanned downtime by detecting and diagnosing faults early.

Increased uptime: The systems can help to extend the life of machinery by monitoring for potential failures and taking corrective action before they occur.

Improved safety: The systems can help to prevent accidents by detecting and isolating hazardous conditions.

Reduced maintenance costs: The systems can help to reduce maintenance costs by identifying problems before they cause major damage.

Improved efficiency: The systems can help to improve plant efficiency by optimizing the operation of machinery.

If you are looking for a reliable and effective way to monitor your rotating machinery, the Bently Nevada 3500 Series is a great option. The systems are used by leading organizations around the world to improve the reliability, availability, and safety of their plants.

Recommended related products:

The bently 3500 frame instrumentation system primarily consists of:

bently 3500/05 system frame: model 14 module slots 3500/05-01-01-00-00-01; 7 slots 3500/05-02-04-00-00-01

bently 3500/15 Power Supply (new): model 3500/15-05-05-00 (front panel 106M1079-01, rear back panel 106M1081-01)

bently 3500/20 Frame Interface Module

bently 3500/22M Frame Interface Module with TDI : Model 3500/22-01-01-00 (front panel 288055-01, rear back panel 146031-01)

bently 3500/25 Keyer Module : Model 3500/25-01-01-00 (front panel 149369-01, rear back panel 125800-01)

bently 3500/32 4-Channel Relay Module: Model 3500/32-01-00 (Front Panel 149986-02, Rear Backplane 125720-01)

bently 3500/33 16-Channel Relay Module: Model 3500/33-01-00 (front panel 149986-01, rear back panel 149992-01)

bently 3500/34 TMR Relay Module

bently 3500/40M Proximitor Displacement Monitor: Model 3500/40-01-00 (front panel 176449-01, rear back panel 125680-01)

bently 3500/42M Displacement/Velocity Acceleration Monitor: Model 3500/42-01-00(front panel 176449-02, rear back panel 128229-01)

bently 3500/44M Aerodynamic Monitor

bently 3500/45 Differential Expansion/Axial Position Monitor: Model 3500/45-01-00(front panel 176449-04, rear back panel 135137-01)

bently 3500/46M Utility Monitor

bently 3500/50 RPM Module: Model 3500/50-01-00-01 (front panel 288062-02, rear back panel 133442-01)

bently 3500/53 Overspeed Detection Module

bently 3500/60 and 3500/61 Temperature Monitors: Models 3500/60-01-00 (front panel 163179-01, rear back panel 133819-01);

3500/61-01-00(163179-02, 133819-02)

bently 3500/62 Process Variable Monitor: Model 3500/65-01-00 (front panel 14598802 ,rear back panel 17210301)

bently 3500/64M Dynamic Pressure Monitor

bently 3500/72M Piston Rod Position Monitor

bently 3500/77M Cylinder Pressure Monitor

bently 3500/90 Communication Gateway

bently 3500/92 Communication Gateway: Models 3500/92-01-01-00 (136180-01, 125736-01) and 3500/92-02-01-00 (136180-01, 133323-01)

bently 3500/01-01 configuration software

bently 3500/06 Protective Enclosures

bently 3500/08 Troubleshooting Connection Panel

bently 3500 Internal Safety Barrier: Model 3500/04 (136719-01, 138257-01)

bently 3500/93 Stand Alone Display

bently 3500/93 LCD Display Unit

bently 3500/94 VGA Display Unit

bently 3500/95 User Interface Workstation

For more branded products click here:https://www.plcdcsmodule.com

(2).The 2300 Series Vibration Monitor is highly regarded for its cost - effectiveness, independence, and compact design. In small and medium - sized power generation enterprises, after a gas turbine is installed with this monitor, it can continuously and stably monitor the vibration status of the equipment. It meets the basic monitoring requirements of enterprises for gas turbines at a relatively low cost, ensures the stable operation of the equipment, and helps enterprises achieve efficient power generation.

Product Models & Features

2300/20 4–20mA Output: Configurable 4–20mA output enables integration with Distributed Control Systems (DCS) for remote, centralized monitoring.

Versatile Channel Support: Includes one velocity/keyphasor channel compatible with proximity sensors, magnetic pickups, and proximity switches.

Protected Buffered Outputs: Three buffered sensor outputs (with keyphasor) feature EMI/short-circuit protection and BNC connectors for reliable signal integrity.

2300/25 Model System 1 Classic Connection: Integrates with Trendmaster SPA interfaces, leveraging existing DSM SPA infrastructure for enhanced system interoperability and condition-based management.

Programmable Relay Outputs: Two relays for flexible control/alarm triggering, critical to operational safety.

Application Fields

Power Generation:Cost-effective monitoring of gas turbines and equipment in small-to-medium plants to prevent vibration-related failures, ensuring stable operation and reduced maintenance costs.

Oil & Gas:Monitors drilling rigs, pumps, and pipeline equipment in harsh environments, mitigating vibration-induced leaks or mechanical damage to enhance safety and productivity.

Water Treatment:Tracks pumps, mixers, and fans to maintain system reliability and water quality by optimizing operational parameters.

Manufacturing & Beyond:

Paper Industry: Monitors paper machines, pulpers, and dryers to minimize downtime and improve product quality.

General Equipment: Covers cooling tower fans, compressors, motors, and mining/cement machinery, boosting efficiency and operational safety across industries.

Sensors and Transmitters

3005319639

3005319639