Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. The 2300/20 vibration monitor is a cost-effective continuous vibration monitoring and protection device, specifically designed for mechanical equipment of medium to low criticality. It is suitable for various industries such as oil and gas, power generation, water treatment, pulp and paper, manufacturing, mining, and cement. It can monitor various units or individual enclosures corresponding to its number of channels and provides advanced signal processing functions.

DATA SHEET

Bently Nevada 230020.pdf

Bently Nevada 230020.pdf

Monitoring and Protection: Enables continuous monitoring and protection of equipment.

Input and Sampling:

- Features two acceleration/velocity/proximity input channels with synchronous sampling for advanced diagnostics.

- One dedicated velocity channel supporting proximity probes, magnetoelectric sensors, and proximity switch sensors.

- All three input channels are compatible with process variables.

Measurement and Alarm:

- Provides real-time key measurements, including acceleration peak-to-peak, acceleration RMS, acceleration peak-to-peak/RMS, velocity peak-to-peak, velocity RMS, displacement peak-to-peak, displacement RMS, and velocity, with configurable alarms.

- Each channel has one measurement group and an additional 2 bandpass measurements.

Output:

- Equipped with two 4-20mA outputs with internal current loop power supply.

- Two relay outputs with programmable setpoints.

- Three buffered sensor outputs (including a keyphasor signal) with short-circuit and EMI protection, each accessible via BNC connectors.

Communication and Configuration:

- Supports Ethernet 10/100 Base-T communication, configurable via Bently Nevada Monitor configuration software (with RSA encryption).

- Compatible with Ethernet Modbus® protocol.

Display and Operation:

- Real-time numerical and status display via LCD and LEDs.

- Local contacts for positive operations such as channel bypass, configuration lock, and reset.

- External buttons for resetting latched alarms and relays.

- A hidden button for three functions: displaying monitor information, adjusting LCD contrast, and resetting settings to defaults.

Inputs

ICP Accelerometer:

- Configurable bandpass filter: 0.2Hz to 20kHz

- Scale factor range: 5 to 1000mV/g

- Full-scale range: 2 to 80g peak

- Current source: 3.3mA±5%

- Open-circuit voltage: -21 to -24VDC

Velocity:

- Configurable bandpass filter: 0.2Hz to 20kHz

- Scale factor range: 5 to 1000mV/in/s

- Full-scale range: 0 to 50in/s peak

Radial Vibration:

- Configurable bandpass filter: 0.2Hz to 20kHz

- Scale factor range: 5 to 1000mV/mil

- Full-scale range: 0 to 160mil peak-to-peak

Thrust Channel: Scale factor range: 5 to 1000mV/mil.

Process Variable Channel: Supports most units, with temperature as the default.

Channel Hardware Specifications:

- Configurable upper normal limit: -0.25 to -22V (higher than lower normal limit)

- Lower normal limit: -0.25 to -22V (lower than upper normal limit)

- Accuracy: ±1% of full-scale range

- Input channels with independent 24-bit ADC

- Compatible with Bently sensors or 2/3-wire custom sensors (for accelerometers, velocity sensors, and proximity sensors)

Velocity/Keyphasor:

- Keyphasor sensors support multiple events per revolution and event ratios, with velocity input up to 20kHz.

- Threshold voltage resolution: 0.1VDC

Proximity Sensor Interface:

- Supply voltage: -22.8 to -25.2VDC

- Maximum rated current: 15mA

- Short-circuit current: 15.1mA to 23.6mA

- Accuracy: ±1% of full-scale range

- Input impedance: 10kΩ (3-wire voltage mode)

- Speed range: 1 to 120,000rpm

Proximity Switch Interface:

- Supply voltage: -10 to -24VDC

- Lower normal limit: -2.75±0.05V

- Speed range: 1 to 120,000rpm

Magnetoelectric Sensor:

- Input voltage up to ±125V (250V peak-to-peak)

- Speed range: 200 to 120,000rpm

Contact Inputs:

- 3 contact functions: configuration lock, latched alarm/relay reset, monitor alarm/relay inhibit

- Activated state resistance: 0 to 10kΩ

- Deactivated state resistance: 150kΩ to infinity

Outputs

Buffered Outputs: Three buffered outputs via BNC connectors, including 2 vibration outputs and 1 velocity output.

Relays:

- Two dry contact outputs, configurable as normally energized or de-energized, with no output feedback confirmation.

- Maximum switching power in non-hazardous areas: 1500VA AC/150Watts DC.

- Maximum switching voltage and current in hazardous areas: 6A@24VAC, 5A@30VAC, 5.8A@24VDC, 4A@30VDC.

4-20mA Outputs:

- 4-20mA output proportional to the full scale of the associated measurement; each output variable configurable via software.

- Voltage compliance: 0 to +12Vdc range (across load)

- Load resistance: 0 to 600Ω

- Resolution: 0.3662uA

- Accuracy over operating temperature range: 1%

- Update rate: 100ms

- Configurable default 2mA clamp current, with no output feedback confirmation.

- Note: The two 4-20mA outputs cannot be used with externally powered loops.

Display and Indicators

LCD Display: Shows machine speed, vibration measurements, setpoints, and configuration information.

LED Indicators:

- OK: Indicates normal monitor operation.

- Protection Fault: Indicates hardware faults affecting alarm confirmation.

- User Inhibit: Indicates alarms/relays are intentionally disabled.

- Bypass: Indicates a user-initiated bypass operation.

- Relay Status: Indicates whether the relay is activated.

- TX/RX: Indicates Ethernet status and communication between the monitor and remote software.

- Speed/Auxiliary Channel Status: Indicates valid speed signal input on the velocity channel or normal operation of auxiliary channels.

- Channel Alarm Status: Alert LED illuminates when any channel is in alarm state; Danger LED illuminates when any channel is in danger state.

Environment and Certifications

Environmental Limits:

- Storage temperature: -40°C to +85°C (-40°F to +185°F)

- Humidity: Up to 95% (non-condensing)

- Vibration limit: 3g

- Real-time clock battery life: 38 years @50°C (122°F) when powered; 12 years @50°C (122°F) when unpowered.

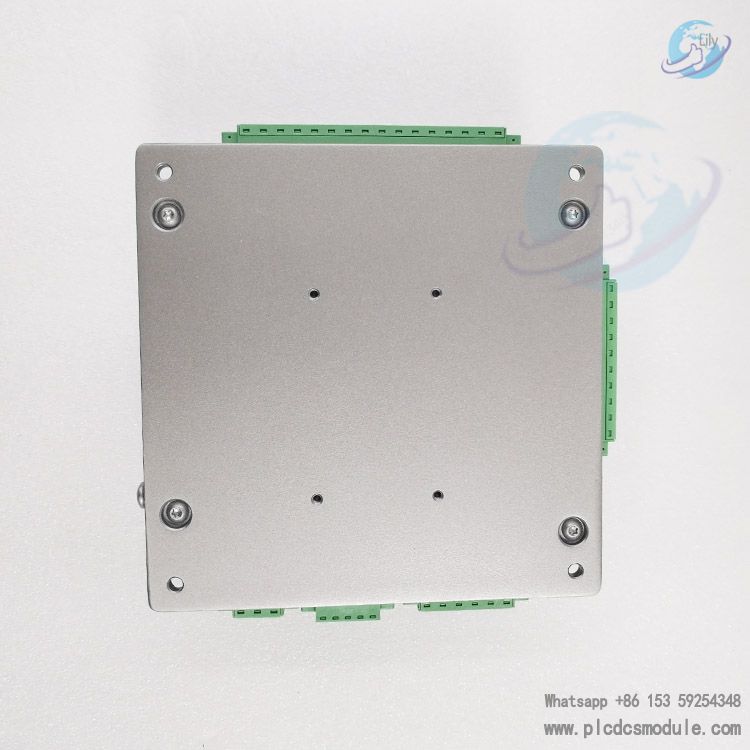

Physical Characteristics

- Dimensions: 127mm x 127mm x 76.2mm (5in x 5in x 3in)

- Weight: 1.03kg (2.26lbs)

- Mounting: Panel mount or DIN rail mount (with adapter).

Model Number: 2300/20-AA-BB, where:

- AA represents certification options (00 = none; 02 = multiple explosive environment certifications including ATEX/IECEx/CSA).

- BB represents the software license for System 1 connection (00 = no license; 01 = with license).

Demonstration Kit: The recommended kit is 2300/20_KIT-003-02-01, which includes: 1 x 2300/20 monitor, 1 x 6ft. (1.8m) shielded Ethernet cable, 2 x accelerometers (200350), 2 x 12ft. (3.6m) accelerometer cables (9571), and 1 x 100M9465-01 BN Monitor configuration software/FW DVD. The 110M7102-01 power supply (DIN rail mount, 100/240AC to 24DC/1.3A, -25°C to 70°C, 22.599107mm) must be ordered separately.

Power Supplies:

- 106M7607-01 (DIN rail mount, 100/240AC to 24DC/1.5A, ATEX certified, 25°C to 70°C, 359995mm; can power up to 4 monitors).

- 110M7102-01 (DIN rail mount, 100/240AC to 24DC/1.3A, UL CID2 certified, -25°C to 70°C, 22.599107mm; can power up to 4 monitors).

- 106M6694-01 (DIN rail mount, 110/220AC to 24VDC/5A, ATEX, IECEx, and UL CID2 certified, -40°C to 70°C, 40130125mm; can power up to 10 monitors).

Housings:

- 105M6193-02 (stainless steel housing, suitable for hazardous areas).

- 105M6193-01 (fiberglass NEMA 4X/IP66 waterproof housing with door window, including monitor mounting plate; for non-hazardous areas).

Cables:

- Various sensor cables and Ethernet cables, such as 9571-AA* (low-cost 2-wire sensor cable) and 138131-AAA (standard 10 Base-T/100 Base-TX shielded Cat 5 cable with RJ-45 connectors).

Software:

- 100M9465-01 BN Monitor configuration software/FW DVD (includes BNMC 5.2 or higher, 2300 series monitor firmware, and 2300 series software guide).

User Manuals:

- 2300 Series Operation and Maintenance Manual (Document 105M0341).

- 2300 Field Wiring Diagram (Document 106M5801).

- 2300 Series Software Guide (Document 107M7626).

- 2300 Series Monitor Installation Guide (Document 121M3029).

Customers who purchased this product are also browsing the following products:

Bently Nevada 2300/25 Vibration Monitors

Bently Nevada 136719-01 Earthing I/O Module

ABB GDC806C6003 3BHE044249R6003 PLC module

Extreme Networks X440-24X-10G X440 series switches

3005319639

3005319639