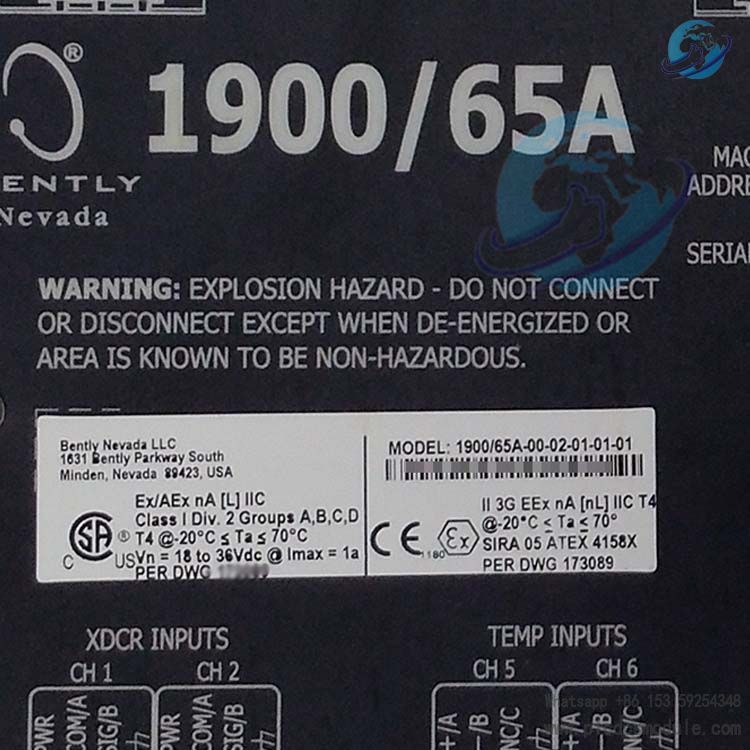

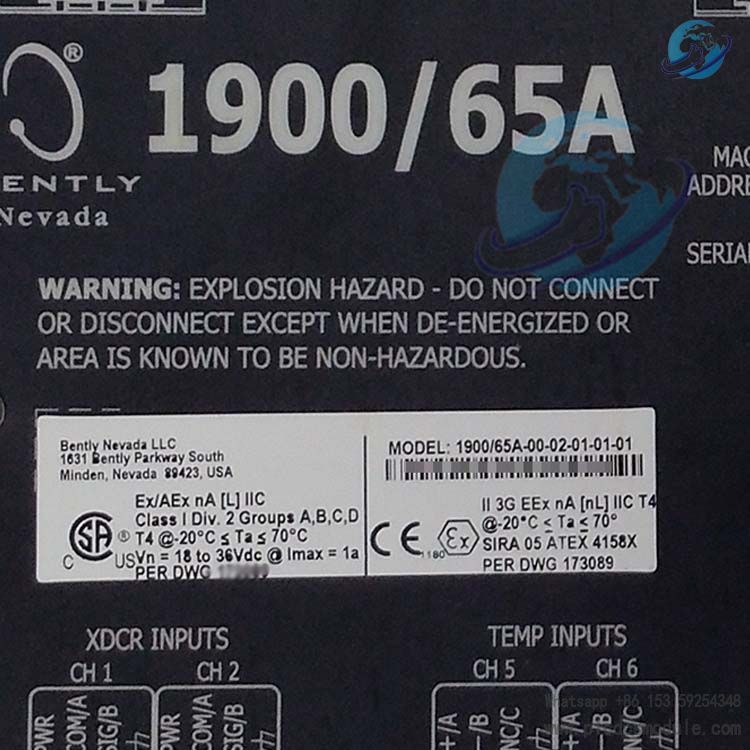

Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. The Bently Nevada 1900/65A-00-02-01-01 Universal Machinery Monitor is a continuous monitoring and protection device designed for equipment across multiple industries and scenarios. Boasting high cost-effectiveness, it serves as an ideal solution for general machinery and processes requiring continuous monitoring and protection. Following standardized parameter configuration (per the 1900/65A-AA-BB-CC-DD-EE coding rule: AA=00 for 18-36Vdc power supply, BB=02 for a display with 10-foot preassembled PVC cable, CC=01 for specific mounting adaptation, DD=01 for multiple certifications, and EE=01 for Modbus communication), this model enables real-time monitoring of key equipment parameters such as vibration, temperature, rotational speed, and displacement. It also supports flexible communication interaction, remote configuration, and alarm control, making it widely applicable in industrial equipment condition monitoring, fault early warning, and safety protection scenarios.

Should you need to obtain the relevant documents, you may download them via the link below:

190065A-00-02-01-01-01.pdf

190065A-00-02-01-01-01.pdf

Core Functions and Application Scenarios

1. Core Monitoring Capabilities

This monitor focuses on the collection of full-status parameters of equipment, covering key indicators such as vibration, temperature, rotational speed, and shaft displacement. Specific details are as follows:

Vibration Monitoring

Supports monitoring of acceleration (including reciprocating acceleration), velocity (including reciprocating velocity), and radial vibration (shaft vibration). It can realize multi-band amplitude measurement through band-pass filtering, and is compatible with 2-wire/3-wire acceleration sensors, piezoelectric velocity sensors, etc.

Displacement and Position Monitoring

Achieves measurement of shaft axial displacement (thrust) and mechanical position through proximity sensors. It supports range adjustment of 1-4mm (thrust) and 1-28mm (position), with flexible zero position setting.

Rotational Speed Monitoring

Adopts proximity sensors, with a range of 100-100,000rpm. The Events Per Revolution (EPR) can be configured within the range of 0.001-1000, and the accuracy reaches ±0.5rpm + 0.015% of the reading.

Temperature Monitoring

4 temperature input channels (Channels 5-8) are compatible with E, J, K, T-type thermocouples and 2-wire/3-wire RTDs. The range covers -200℃ to 1370℃ depending on the sensor type (e.g., K-type thermocouple), with a typical accuracy of ±1℃ (at 25℃ ambient temperature).

2. Applicable Industries and Equipment

With a wide operating temperature range (-20℃ to 70℃), high protection adaptation (supporting NEMA 4X/IP66 waterproof enclosure), and compliance with multiple certifications (ATEX, CSA, FCC, etc.), this equipment can be applied in:

- Petrochemical Industry: Condition monitoring of rotating machinery such as pumps, compressors, and fans;

- Power Industry: Shaft vibration and temperature monitoring of steam turbines and generators;

- Manufacturing Industry: Fault early warning of transmission equipment such as motors and gearboxes;

- Marine and Heavy Industry: Position and rotational speed protection of marine power systems and heavy machinery.

Hardware Parameters and Interface Configuration

1. Input Interface Specifications

Designed in compliance with the 1900/65A universal standard, this model is equipped with 8 core input channels, with detailed parameters specified as follows.

Sensor Input: 4 channels in total, compatible with 2/3-wire accelerometers, velocity sensors and proximity sensors. The key parameters are listed as follows: the input impedance under 3-wire voltage mode is 10 kΩ; the acceleration measurement range is 20–500 m/s² (2–50 g); the velocity measurement range is 10–50 mm/s.

Temperature Input: 4 channels in total, compatible with E/J/K/T-type thermocouples and 2/3-wire RTDs. The key parameters are listed as follows: the thermocouple input impedance is greater than 1 MΩ; the RTD is compatible with 10 Ω Cu, 120 Ω Ni and 100 Ω Pt types.

Inhibit/Reset Input: 2 channels in total, with no compatible sensors specified. The key parameters are listed as follows: the activation impedance is ≤ 50 kΩ (short-circuit); the deactivation impedance is ≥ 500 kΩ (open-circuit). This interface is applicable for remote alarm reset and function inhibition.

2. Output Interface Specifications

The output interfaces cover three categories, namely control, recording and communication, meeting the requirements of data interaction and control across multiple scenarios.

Relay Output: It includes 6 channels of single-pole double-throw (SPDT) relays, supporting customizable switching logic based on "OK, Alert, Danger" statuses. The maximum switching current is 5 A (DC 60 V/AC 30 V); the contact life reaches 100,000 operations (at 5 A/250 Vac).

Recording Output: It includes 4 channels of 4–20 mA analog output, with an accuracy of ±2% within the operating temperature range and an update rate of 100 ms. This interface can map variables from any channel, with a maximum loop resistance of 600 Ω.

Buffered Output: It is a dedicated buffered output for sensor inputs (Channels 1–4), featuring no gain and no scaling. The output impedance is 550 Ω, and the bandwidth is ≥ 40 kHz when directly connected to a display. Short-circuit and EMI protection are provided for this interface.

Communication Interface: Configured with EE=01, it supports Modbus communication, including an Ethernet port and a software-configurable RS232/485 serial port. It can be integrated with DCS, SCADA, PLC or System 1 software, to transmit static variables, statuses, event lists and timestamps.

Software and Configuration Functions

1. Configuration Software Capabilities

This monitor is paired with the 1900 Configuration Software, which enables full-function configuration and management with core features as follows:

- Offline/Online Configuration: Configuration files can be created without hardware connection and downloaded to the device via Ethernet port. Configuration data is stored in non-volatile memory and supports upload for modification.

- Channel and Variable Customization: Each sensor input channel can be configured with 4 variables (e.g., vibration peak/RMS, temperature value). It supports switching between metric and imperial units as well as adjustment of filtering frequency (e.g., 4th-order filtering ranging from 0.5 Hz to 25 kHz for vibration variables).

- Relay Logic Programming: It allows logic configuration with 50 operands per relay. Relay actions can be triggered based on the status combination of single or multiple channels (with AND/OR logic), and both latched and non-latched modes are supported.

- Firmware Upgrade and Diagnostics: It provides hardware identification, manufacturing information query and online firmware upgrade, with built-in fault diagnosis functions (e.g., sensor open-circuit detection).

2. Display and Local Operation

Configured with BB=02, this model is equipped with a display/keypad module with a 10-foot assembled PVC cable, featuring the following core characteristics:

- Display Function: Equipped with a backlit LCD screen, it supports real-time data viewing of each channel, alarm status indication (with OK/Alert/Danger indicator lights), and bypass/trip multiply mode indication (with dedicated indicator lights).

- Local Operation: It allows minor configuration modifications (e.g., setpoint adjustment). The maximum distance between the display and the monitor module is 75 meters (250 feet), supporting independent installation.

- Status Indication: The monitor module is equipped with a built-in "operating status LED", while the display module adds channel activation indicator lights, providing intuitive feedback on the device's working status.

Installation and Physical Specifications

1. Installation Configuration (Compatible with CC=01)

In accordance with the coding rules, this model supports flexible installation methods, with core adaptation solutions as follows:

- DIN Rail Mounting: Compatible with 35mm standard DIN rails and requires the 168374 mounting clips for assembly. The monitor module has dimensions of 196.9mm×149.4mm×74.4mm (L×W×H) and weighs 0.77kg.

- Wall Mounting: Utilizes the 168495 wall mounting plate. The display module has dimensions of 196.9mm×149.4mm×32.8mm and weighs 0.40kg.

- Waterproof Mounting: An optional 168944 NEMA 4X/IP66 fiberglass enclosure (dimensions: 300.2mm×249.4mm×209.8mm) is available, suitable for outdoor or humid environments.

2. Power Supply and Environmental Parameters

- Power Supply Requirements: Configured with AA=00, it supports DC power supply of 18–36Vdc, with a typical operating current of 0.35A (8.5W) and a maximum current of 1.0A (14W), and is equipped with short-circuit protection.

- Environmental Adaptability: The operating temperature ranges from -20℃ to 70℃, and the storage temperature ranges from -30℃ to 90℃. It can withstand a relative humidity of 95% (non-condensing), and its EMI resistance complies with industrial standards.

Accessories and Upgrade Options

1. Standard and Optional Accessories

This model comes with core accessories and supports adaptation with expansion components, with common accessories detailed as follows:

- Standard Accessories: 1900 Configuration Software (CD), which is used for device configuration and management.

- Display Accessories: 167699-02 display module, which is used for local data viewing and operation and is matched with BB=02 configuration.

- Mounting Accessories: 168374 DIN rail clips and 168495 wall mounting plates, which are used to adapt to different installation methods.

- Power Supply Accessories: 02200794 power supply (110/220Vac to 24Vdc), which needs to be additionally configured if AC power supply is required.

- Safety Barrier Accessories: 284785 MTL 7728 and 175502 MTL 7796, which are used for signal isolation of sensors in hazardous areas.

2. Upgrade Options

- Communication Upgrade: To expand communication capabilities, the 1900/01 communication upgrade package can be ordered, which supports Modbus/TCP to RTU conversion.

- Firmware Upgrade: Device firmware can be upgraded online via the configuration software to obtain new functions and performance optimizations.

- Sensor Expansion: It is compatible with the full range of Bently Nevada sensors (such as 330400 accelerometers and 3300 XL proximity systems), and sensor types can be replaced according to monitoring requirements.

Model Selection and Ordering Information

This model complies with the standardized ordering code of the 1900/65A series (1900/65A-00-02-01-01-01). The meaning of each field and optional configurations are as follows, facilitating users to make adjustments according to their needs:

The coding positions are defined as AA-BB-CC-DD-EE. AA represents the power supply type; the configuration of this model is 00, which refers to 18–36Vdc power supply, and the other optional configuration is 01, which refers to 110–220Vac power supply requiring an external power supply. BB represents the display and cable type; the configuration of this model is 02, which refers to the 10-foot assembled PVC cable, and the other optional configurations include 00 for no display, 01 for display without cable and 04 for TEF cable. CC represents the installation adaptation type; the configuration of this model is 01, which refers to specific installation, and the other optional configurations include 04 for 1900/55 replacement kit and 07 for ProTIM enclosure. DD represents the compliance certification type; the configuration of this model is 01, which refers to multiple certifications, and the other optional configuration is 00 for no additional certification. EE represents the communication function type; the configuration of this model is 01, which refers to Modbus communication, and the other optional configuration is 00 for no communication function.

Bently Nevada Related Product Models

1900/65A(General Purpose Equipment Monitor): As the basic universal model of the series, it is equipped with 4 sensor input channels and 4 temperature input channels. It supports 2/3-wire accelerometers, velocity sensors, proximity sensors as well as a variety of thermocouples and RTDs. The output includes 6 relay channels and 4 channels of 4-20mA recorder outputs, with Modbus communication compatibility. It is an ideal choice for low-cost general-purpose monitoring scenarios.

1900/65B (General Purpose Equipment Monitor): Based on the 1900/65A model, it expands the number of channels, providing 6 sensor input channels plus 6 temperature input channels. It adds Profinet communication support and is suitable for cluster monitoring scenarios of multiple pumps, fans and other equipment in a production line, being compatible with Siemens industrial bus systems.

1900/65C (General Purpose Equipment Monitor): It retains the 4+4 channel input configuration of the 1900/65A model, upgrades the explosion-proof rating to ATEX II 2 G Ex d IIC T6, and expands the operating temperature range to -40℃~+85℃. Specifically designed for Class I Div 1 high-risk areas such as petrochemical and coal mining industries, it is suitable for equipment monitoring in extreme environments like underground fans and compressors in refining and chemical installations.

3500/25 (Axial Position Monitor): Specialized in monitoring the axial displacement of rotating equipment shafts, it is compatible with various eddy current probes and supports user-defined alarm limits. It serves as a core component for the shafting safety protection of key equipment such as steam turbines and compressors.

3500/42 (Radial Vibration Monitor (Accelerometer)): It can connect to 2/3-wire acceleration sensors to accurately monitor the radial vibration amplitude (peak/RMS) of equipment. It supports flexible filtering and range configuration, and is widely applicable to the vibration monitoring needs of equipment such as fans and pump units.

3500/45 (Radial Vibration Monitor (Eddy Current Probe)): It needs to be used with the 3500/40M Proximitor Interface Module. It realizes real-time monitoring of shaft radial vibration through eddy current probes, with a measurement accuracy of ±0.1% FS. It is a core module for vibration monitoring of key shafting equipment such as generators.

3500/50 288062-02 (Speed/Zero Speed/Phase Reference Monitor): Equipped with dual-channel inputs, it is compatible with proximity switches and magnetoelectric speed sensors. It can accurately measure speed (1-100,000 rpm), rotor acceleration and reverse rotation times, while providing overspeed and under-speed alarm functions. It is suitable for speed monitoring and protection of equipment such as generator sets and turbines.

3500/40M (Proximitor Interface Module): It provides stable power supply for eddy current probes, converts the original signals collected by the probes and routes them to vibration monitor modules such as the 3500/45, ensuring the stability and accuracy of signal transmission.

3500/22M (Temperature Monitor): It supports connection to E, J, K, T-type thermocouples or RTD sensors, and can simultaneously monitor the temperature of key parts such as bearings and windings. It is equipped with 16 input channels with a measurement accuracy of ±0.5℃, suitable for the temperature protection needs of equipment such as motors and compressors.

3005319639

3005319639