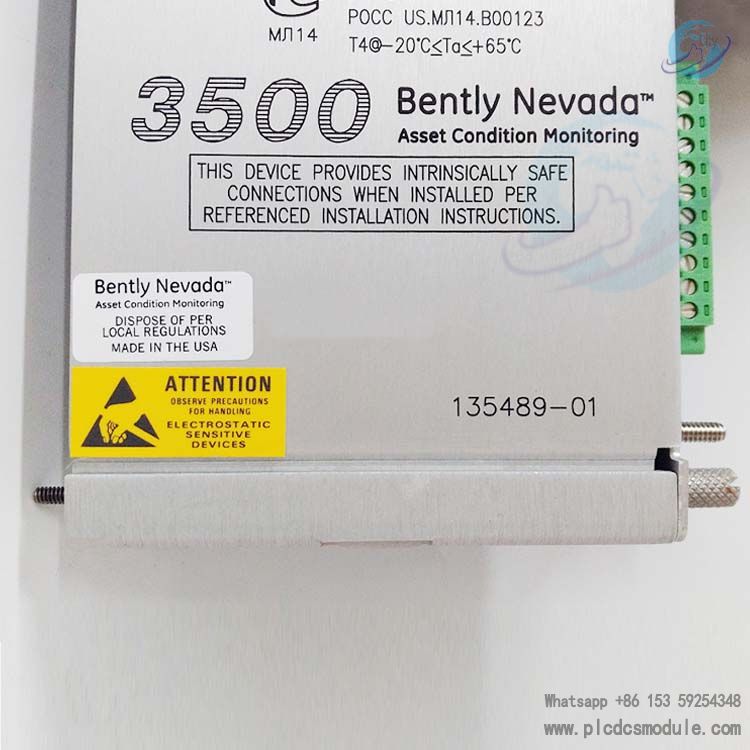

BENTLY NEVADA 3500/42M is a four-channel monitor primarily designed to receive input signals from proximity sensors and seismic sensors. It can condition these signals to provide various vibration and position measurements, and compare the conditioned signals with user-programmable alarm thresholds. Among them, 176449-02 is the front card and 135489-01 is the rear card, which must be used in combination to jointly achieve the functions of signal acquisition, processing, and system interaction.

Basic Information

Model: 3500/42M

Functional Positioning: A four-channel monitor designed to receive signals from proximity transducers and seismic transducers, providing vibration and position measurements while supporting user-programmable alarm thresholds.

Compatible Components:

Front Card (I/O Module): 176449-02 (non-isolated type) or 135489-01 (isolated type with internal barriers).

Rear Card (I/O Module): Must be used in conjunction with the front card, supporting different transducer types (e.g., Prox/Accel, Velomitor).

Data Sheet:

![]() BENTLY NEVADA 3500-42M 176449-02 135489-01 Proximitor Seismic Monitor.pdf

BENTLY NEVADA 3500-42M 176449-02 135489-01 Proximitor Seismic Monitor.pdf

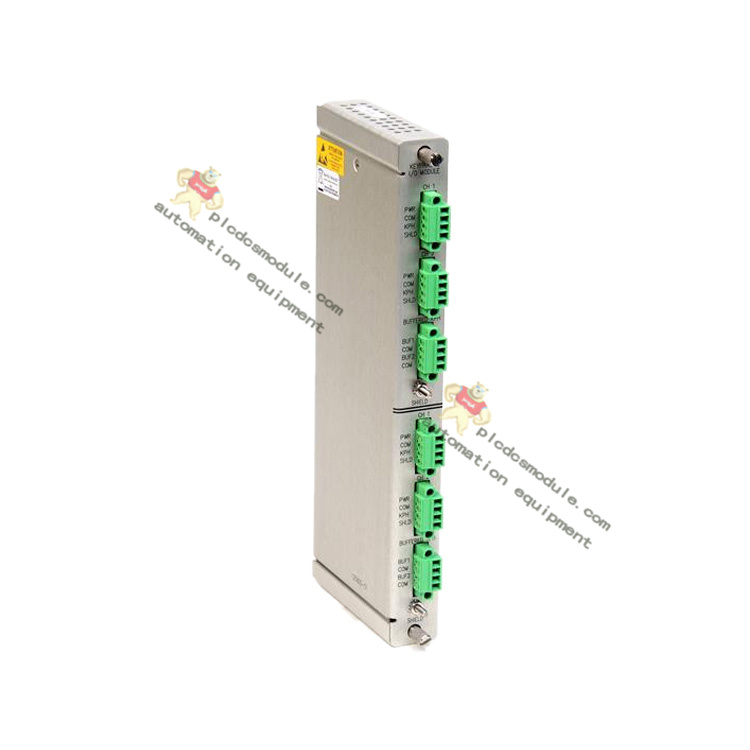

Front Card 176449-02

Function: As the front card of the 3500/42M, the 176449-02 is primarily responsible for interacting with external devices, such as connecting proximity sensors and seismic sensors, receiving signals from these sensors, and transmitting them to the 3500/42M module for processing. It may also have signal preprocessing functions (e.g., filtering, amplification) to improve signal quality and stability, ensuring the accuracy of subsequent measurements and comparisons.

Features: Equipped with standard input interfaces, it is highly compatible with various types of proximity sensors and seismic sensors. In terms of electrical performance, it has excellent anti-interference capabilities, enabling stable operation in complex industrial environments and ensuring reliable signal transmission.

Rear Card 135489-01

Function: As the rear card, the 135489-01 mainly assumes the role of communication and interaction with other modules or systems. For example, it may be responsible for transmitting data processed by the 3500/42M module to the host computer monitoring system or connecting with other relevant protection relay modules to trigger relay actions when monitored parameters exceed preset thresholds (e.g., interlock shutdowns for equipment protection). Additionally, the rear card may provide auxiliary functions such as power management and signal distribution for the front card and the module itself to ensure the normal operation of the entire monitoring system.

Features: With suitable communication interfaces, it can effectively communicate with various external devices or systems, and its communication protocols are typically compatible with other modules in the 3500 series for easy system integration. In terms of reliability, it has good electrical isolation and protection measures to prevent external electrical interference from affecting the internal circuit of the module and protect external devices from module failures.

Collaborative Operation

The front card (176449-02) and rear card (135489-01) are indispensable components of the 3500/42M monitor. They work in tandem to enable the 3500/42M to monitor vibration and position in rotating machinery. The front card focuses on sensor signal input and preprocessing, while the rear card prioritizes data communication and system interaction. Their close collaboration ensures the 3500/42M accurately monitors equipment status, triggers timely alarms, and sends control signals, providing robust protection for the safe operation of rotating machinery.

Hardware Connection

Physically, the front and rear cards are connected via specific interfaces or buses to facilitate signal and data transmission. This connection ensures high-speed, stable communication between the two components, enabling efficient operation of the entire monitoring system. Additionally, they are electrically linked to other parts of the 3500/42M module, forming a complete monitoring unit.

Functional Complementarity

The front and rear cards assume distinct but complementary roles. The front card’s signal acquisition and preprocessing provide accurate data for the rear card’s data transmission and system interaction. Conversely, the rear card’s communication and control functions leverage the information collected by the front card to coordinate with external devices. Together, these functions enable comprehensive monitoring and protection of rotating machinery, highlighting their interdependence in achieving the system’s objectives.

BENTLY NEVADA 3500/42M Proximitor/Seismic Monitor Product Specification Parameters

Input Characteristics

Supports inputs from proximity sensors (Proximitor), velocity sensors (Velomitor), and accelerometers (Accelerometer), with 4 independent channels that support paired configuration (e.g., Channels 1+2, 3+4). Each channel pair can perform up to 2 monitoring functions simultaneously (e.g., radial vibration + eccentricity). The input signal range for proximity sensors is -20 VDC to +20 VDC (typical), accelerometers support ±5 V or ±10 V input depending on the model, velocity sensors adapt to 0-0.5/1.0/2.0 full-scale outputs, and the standard I/O input impedance is 10 kΩ (applicable to Proximitor and accelerometer inputs).

Signal Processing and Measurement Parameters

Monitors vibration parameters such as radial vibration, acceleration, velocity, and REBAM (rolling bearing fault monitoring), as well as position parameters such as shaft absolute position, thrust position, eccentricity, and differential expansion. It also supports circular acceptance region and 1X/2X vector analysis (phase and amplitude). Sensitivity specifications include 3.94 mV/μm (100 mV/mil) or 7.87 mV/μm (200 mV/mil) for radial vibration/shaft absolute position, 10 mV/(m/s²) (100 mV/g) for acceleration, and 20 mV/(mm/s) pk (500 mV/(in/s) pk) for velocity. Filtering functions include user-programmable low-pass/high-pass/band-pass filtering (cutoff frequency range: 0.09 Hz to 4000 Hz), 1X/2X vector frequency tracking (stopband rejection ≥ -57.7 dB), and REBAM-specific filtering (programmable Spike/Element/Rotor frequencies for bearing fault characteristic frequency monitoring). Measurement accuracy is ±0.33% of full scale (typical) and ±1% maximum for direct measurements, with REBAM phase error ≤ 3°.

Output Characteristics

Analog outputs include independent +4 to +20 mA recorder outputs per channel (load 0-600 Ω, short-circuit protected), 550 Ω impedance BNC buffered transducer outputs, and 300 Ω impedance shaft absolute position outputs. Digital communication is achieved via the 3500 rack backplane with other modules (e.g., 3500/22M transient data interface), supporting protocols like Modbus and Profibus (matching modules required). Alarm outputs connect to 3500/32/33/34 relay modules through the rear card, supporting dual thresholds for Alert and Danger. Delay settings range from 1-60 seconds for alerts and 0.1-60 seconds for dangers (up to 400 seconds for REBAM). Front-panel LEDs indicate operational status (OK), communication status (TX/RX), and bypass mode (Bypass).

Electrical and Environmental Parameters

Input voltage: 24 VDC (typical), power consumption: 7.7 W. Barrier-equipped modules (e.g., 135489-01) meet explosion-proof standards, with Proximitor barrier power parameters: Vmax 26.80 V, Imax 112.8 mA, Rmin 237.6 Ω; seismic barrier: Vmax 27.25 V, Imax 91.8 mA, Rmin 297 Ω. Operating temperature: 0°C to +65°C (for modules with internal barriers), storage temperature: -40°C to +85°C, humidity: 95% non-condensing, compliant with industrial seismic standards. Certifications include cNRTLus (Class I, Division 2), ATEX/IECEx (Zone 2), EMC/LV directives, and RoHS compliance.

Mechanical Specifications

Monitor module dimensions: 241.3 mm × 24.4 mm × 241.8 mm (H×W×D), weight: 0.91 kg. I/O modules: non-barrier type dimensions 241.3 mm × 24.4 mm × 99.1 mm (0.20 kg), barrier type 241.3 mm × 24.4 mm × 163.1 mm (0.46 kg). Mounting via 3500 series rack (1 front slot + 1 rear slot).

Matching Modules and Spare Parts

Matching I/O modules include non-isolated 128229-01 with internal terminals, isolated 135489-01 with internal barriers (4-channel Prox/Accel), and shaft absolute position monitoring 138708-01 (internal terminals). Spare parts include connector shunts (e.g., 00530843), Euro-style connectors (e.g., 00580434), and cable assemblies with selectable lengths (e.g., 129525, 5-100 feet).

Software Requirements and Key Relationships

Firmware/software must meet 3500/01 framework software ≥ V2.50, 3500/02 communication module software ≥ V2.20, and DM2000 management software ≥ V3.10 (supporting advanced functions like REBAM). The front card (176449-02) handles sensor signal access and preprocessing (filtering, amplification, BNC interface), while the rear card (e.g., 135489-01) provides electrical isolation in explosion-proof environments and connects to relay modules and upper-level systems for alarm output and data communication. The two cards are electrically connected via the rack backplane, working together to form a complete monitoring unit.

Customers who purchased this product are also browsing the following products:

BENTLY NEVADA 3500/42M 176449-02 Proximitor Seismic Monitor

BENTLY NEVADA 106M1079-01 3500/15 Universal AC Power Supply

HONEYWELL MC-PDIY22 ASSY 80363972-150 Digital Output Processor Module

GE IS200WETBH1BBA Mark VIe Wind WETB Board

EMERSON OVATION 5X00063G01 HART 8-Channel Analog Output Module

3005319639

3005319639