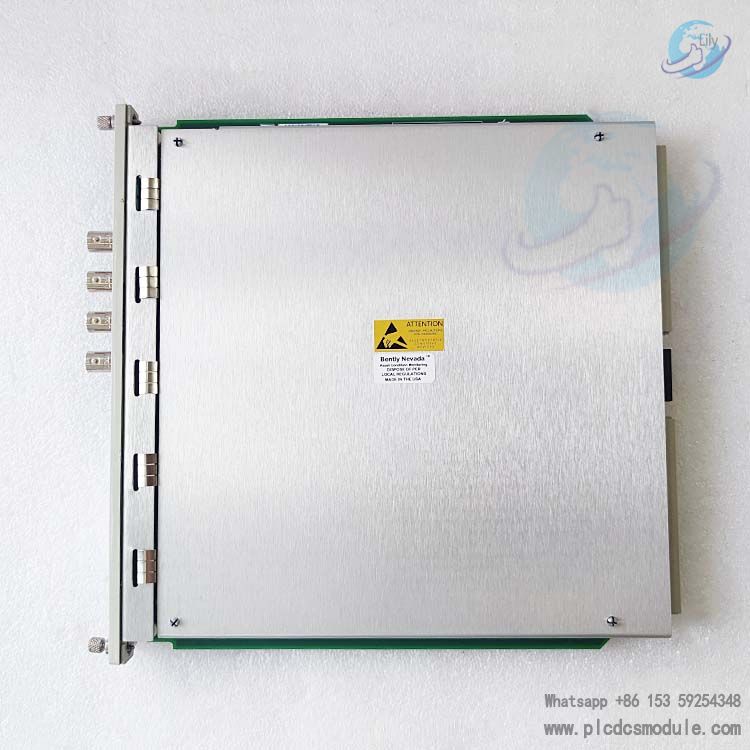

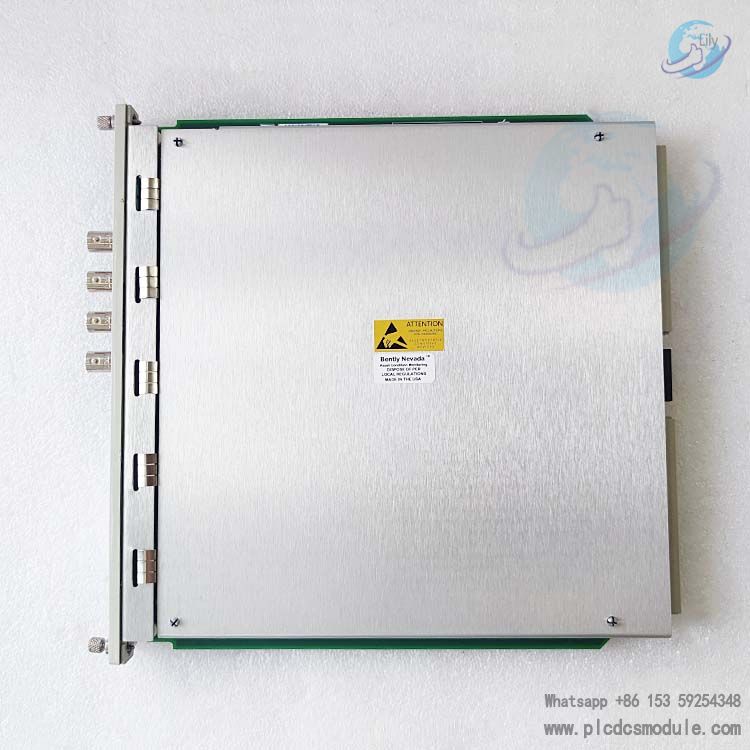

Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. The 3500/42M 176449-02 is a four-channel Proximitor Seismic Monitor in BENTLY NEVADA 3500 series monitoring system, primarily used for vibration and position monitoring of industrial mechanical equipment to ensure safe equipment operation.

Basic Information

Model: 176449-02

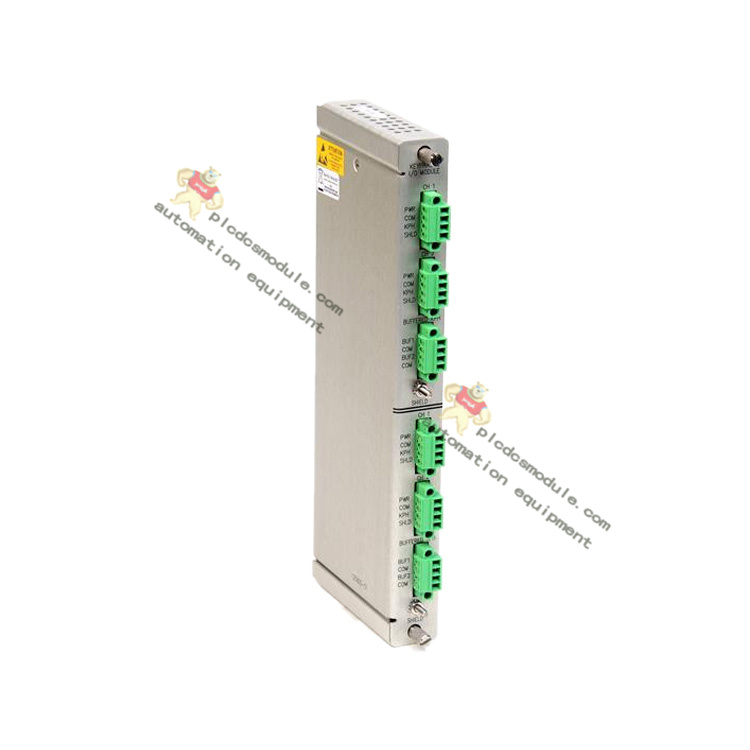

Functional Positioning: As the front card (non-isolated I/O module) of the 3500/42M, it is responsible for connecting proximity sensors, velocity sensors, and accelerometers, receiving raw signals and performing preprocessing (such as filtering and amplification), and transmitting them to the monitor module via BNC interfaces.

Matching Relationship: Must be used in conjunction with a rear card (e.g., 135489-01) to achieve signal interaction through the rack backplane.

176449-02 Sensor and Signal Input

The 176449-02 supports the following sensor types:

- Proximity Sensors (Proximitor): Used for measuring shaft displacement, vibration, and other parameters.

- Velocity Sensors (Velomitor): Measure vibration velocity.

- Accelerometers (Accelerometer): Measure vibration acceleration.

Input Characteristics:

- Channels: 4 independent channels, supporting paired configuration (e.g., Channels 1+2, 3+4), with each pair capable of performing up to 2 monitoring functions simultaneously (e.g., radial vibration + eccentricity).

- Signal Range:

- Proximity sensors: -20 VDC to +20 VDC (typical).

- Accelerometers: ±5 V or ±10 V (model-dependent).

- Velocity sensors: Adapt to 0-0.5/1.0/2.0 full-scale outputs.

- Input Impedance: 10 kΩ (applicable to Proximitor and accelerometer inputs).

Signal Processing and Output

Signal Preprocessing Functions:

- Filtering: Supports user-programmable low-pass/high-pass/band-pass filtering, with cutoff frequency ranges from 0.09 Hz to 4000 Hz (e.g., direct filtering -3 dB points at 4 Hz to 4000 Hz).

- Amplification: Adjustable sensitivity, for example:

- Radial vibration/shaft absolute position: 3.94 mV/μm (100 mV/mil) or 7.87 mV/μm (200 mV/mil).

- Acceleration: 10 mV/(m/s²) (100 mV/g).

- Velocity: 20 mV/(mm/s) pk (500 mV/(in/s) pk).

Output Characteristics:

- Buffered Transducer Outputs:

- Each channel is equipped with a BNC interface, 550 Ω output impedance, and short-circuit protection.

- Signal types: Conditioned vibration/position signals (e.g., amplitude, displacement, velocity).

- Communication with Monitor Module: Transmits preprocessed signals to the 3500/42M main module via the rack backplane for further analysis and alarm processing.

Mechanical and Electrical Specifications

Mechanical Parameters:

- Dimensions: 241.3 mm × 24.4 mm × 99.1 mm (non-barrier I/O module corresponding to the front card).

- Weight: 0.20 kg (non-barrier type).

- Mounting: Installed in the front slot of the 3500 series rack, used in conjunction with the rear card (rear slot).

Electrical Parameters:

- Power Supply: Uniformly powered by the 3500 rack, with typical power consumption coordinated with the main module (overall power consumption 7.7 W).

- Anti-Interference: Equipped with signal conditioning circuits to improve electromagnetic interference resistance, but without built-in explosion-proof barriers (requires matching with rear cards for explosion-proof functionality).

Matching and Compatibility

Rear Card Matching:

- Recommended to pair with 135489-01 (isolated rear card with internal barriers) for explosion-proof environments, providing electrical isolation and relay output interfaces.

- The rear card is responsible for further processing signals from the front card and connecting to upper-level systems (e.g., DCS) or relay modules (e.g., 3500/32/33/34) to achieve alarm and control functions.

Software Compatibility:

- Requires 3500 series rack configuration software (e.g., 3500 Rack Configuration Software) for channel programming and parameter setting.

- Supports firmware upgrades, requiring 3500/01 framework software ≥ V2.50 and 3500/02 communication module software ≥ V2.20.

Application Scenarios

- Conventional Industrial Environments: Suitable for non-explosion-proof scenarios, directly connecting to sensors for signal preprocessing.

- Combination with Explosion-Proof Modules: In hazardous areas, it must be combined with a rear card (e.g., 135489-01) to achieve explosion-proof certifications (e.g., ATEX/IECEx Zone 2) through internal barriers.

Key Correlations in Documentation

Division of Labor Between Front and Rear Cards:

- Front Card (176449-02): Focuses on signal acquisition and preprocessing ("front-end sensing").

- Rear Card (e.g., 135489-01): Focuses on signal output and system interaction ("back-end execution"), including alarm triggering, data communication, and power management.

Collaboration Logic: The two are electrically connected via the rack backplane. The front card's raw signals are processed and transmitted by the rear card to external systems, jointly forming a complete monitoring unit.

Application Scenarios

Rotating Machinery Monitoring: Used for online condition monitoring of large rotating equipment such as steam turbines, compressors, generators, and pumps.

Preventive Maintenance: By analyzing real-time vibration and position data, it identifies equipment faults in advance (e.g., bearing wear, rotor imbalance, shaft misalignment) to avoid unplanned downtime.

Industrial Automation Systems: Interacts with PLC and DCS systems to achieve equipment protection and automated control of production processes.

Differences from Similar Products

Integrated Design: Simultaneously supports input from proximity sensors and seismic sensors without additional modules, simplifying the system architecture.

High-Precision Measurement: Employs advanced signal processing algorithms to ensure accurate vibration and position measurements, making it suitable for monitoring critical parameters of precision machinery.

Compatible Product Models for Bently Nevada 3500/42M

- 3500/01 Frame Interface Module

- Connects sensors to the monitoring system, serving as the foundation for the entire 3500 series. Provides electrical connections and communication interfaces for other modules.

- 3500/22M Transient Data Interface Card

- Enables communication with System 1 Machinery Management Software, facilitating data exchange between the monitoring system and external management platforms for in-depth equipment analysis.

- 3500/40M Displacement Monitor

- A configurable 4-channel monitor module supporting measurements such as radial vibration, axial position, eccentricity, REBAM, and differential expansion. Complements the 3500/42M for comprehensive rotating equipment monitoring.

- Relay Modules:

- 3500/32 (4-channel Relay Module)

- 3500/33 (16-channel Relay Module)

- 3500/34 (TMR Relay Module)

- These modules interface with the 3500/42M to trigger protective actions (e.g., shutdowns) when monitored parameters exceed preset thresholds.

- Speed Monitoring Modules:

- 3500/50 Speed Module: Measures rotational speed.

- 3500/53 Overspeed Detection Module: Detects excessive speed conditions.

- Together with the 3500/42M, they provide comprehensive operational data for rotating machinery.

- Parameter Monitoring Modules:

- 3500/60 & 3500/61 Temperature Monitors: Measure temperature.

- 3500/62 Process Variable Monitor: Monitors process parameters.

- 3500/64m Dynamic Pressure Monitor: Measures dynamic pressure.

- 3500/65 16-channel Temperature Module: Multi-channel temperature monitoring.

- These modules integrate with the 3500/42M to enable holistic equipment condition monitoring.

- Reciprocating Compressor Monitoring Modules:

- 3500/70M Impact/Velocity Monitor: For reciprocating compressor impact and velocity.

- 3500/72M Rod Position Monitor: Monitors piston rod position.

- 3500/77M Cylinder Pressure Monitor: Measures cylinder pressure.

- Designed for reciprocating equipment, these modules work alongside the 3500/42M for specialized monitoring.

Customers who purchased this product are also browsing the following products:

BENTLY NEVADA 135489-01 3500/42M I/O Module

BENTLY NEVADA 106M1079-01 Universal AC Power Supply

ABB GD9924BE V2 HIEE401091R0002 High-voltage control board

Emerson/Motorola MVME172PA-652SE VME Embedded Controller

Emerson/Ovation 5X00070G04 8 Channel Analog Input module

3005319639

3005319639