HIMA is a highly influential enterprise in the field of industrial safety automation. Founded in 1908, it was initially a small marine engineering company in Mannheim, Germany. After more than a century of development, it has become a world-leading provider of intelligent safety solutions.

HIMA provides safety-related automation solutions for the process and railway industries, covering software and hardware products such as safety controllers and information security software. Its products are widely used in industries such as oil and gas, chemicals, power, railways, logistics, and machine automation. More than 50,000 safety systems with SIL 3 / SIL 4, PL e, and CENELEC SIL 4 levels have been installed and are in operation. In addition to product supply, HIMA also offers one-stop services including consulting, safety engineering, services, and training.

HIMA products have many remarkable features. In terms of safety, the products comply with strict international safety standards, such as IEC 61508, and reach the SIL3 or even higher safety integrity level. They adopt redundant designs and a variety of safety mechanisms, including safety startup, communication, and control mechanisms, etc., to ensure the reliable operation of the system in dangerous situations from multiple aspects and prevent the occurrence or expansion of accidents. High reliability is also a major highlight. Through redundant, fault-tolerant, and fault-separation technologies, the accuracy, timeliness, and sensitivity of the system's hardware and software diagnostics have been greatly improved, and the false alarm rate and missed alarm rate have been reduced. The system fault diagnosis rate exceeds 99.99%, and the average time between failures is more than 200 years. At the same time, the products have good flexibility and scalability. Taking the HIMax product as an example, its xmr structure supports upgradeable redundant configurations, including dual redundancy, quadruple redundancy, etc.; during operation, the software and hardware can be changed and expanded without restrictions, and fully integrated and fully protected power distribution can also be achieved, etc., which can meet the diverse and future expansion needs of different customers in different application scenarios. In addition, HIMA products are relatively convenient for maintenance, providing a user-friendly interface and online diagnostic tools, which are convenient for maintenance personnel to carry out daily maintenance and fault troubleshooting, reducing the maintenance cost.

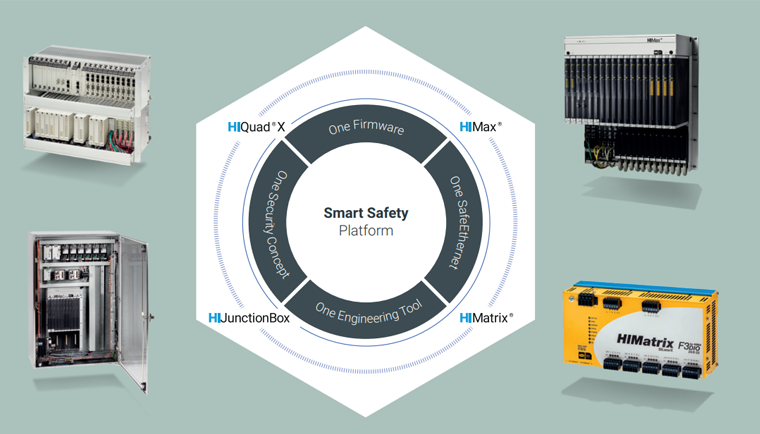

HIMA mainly has the following product series:

Himax series: A powerful and uninterrupted safety control platform, which is the world's first scalable safety platform with built-in automation safety functions. It is suitable for the safety digitization in the process industry, can protect key production processes, and improve the profitability of factories.

HiQuad X series: A SIL 3 level safety platform, which is used to protect key production processes and make factories more profitable.

Himatrix series: A SIL 3 level compact system, which is designed for networked applications in the process industry, machine automation, and safety-related building automation that require high response times. It includes sub-series such as F20, F30, F31, F35, and F60, and each sub-series is suitable for different scenarios.

HiJunctionBox series: It can be deployed dispersedly, reducing the demand for marshalling cabinets, cable trays, and main cables, thus reducing costs.

Planar 4 series: A SIL 4 level safety controller, which is used to protect key systems in process automation.

HiCore 1 series: A TÜV-certified platform based on chips, which can make products safer, reduce costs, and shorten the time to market.

HiQuad X series:

HIQuad H41q/H51q: This is the central module of the HiQuad X series. It is the third-generation central module, which was launched on the market in 1997. In 2018, it was replaced by a new type of central module and entered the replacement stage of the product life cycle. In 2020, it entered the traditional stage.

HIQuad X: The fourth-generation central module launched in 2018. It supports various I/O modules of the previous generation products. Combined with reliable HIQuad I/O modules, it perfects the intelligent platform and enables the system to comply with the new functional standards of IEC 61511 and the automation standards of IEC 62443.

Himatrix series:

HIMatrix F35: A safety-related controller specifically designed for industrial automation control systems. It adopts advanced processor technology and has fast data processing and transmission capabilities. After strict quality control and testing, it has extremely high reliability and stability. It adopts a modular design, allowing you to select controller modules of different models and specifications according to actual needs, and achieve various control strategies and functions through programming and configuration. It has standard interfaces and communication protocols and can be easily integrated into various control systems.

HIMatrix F30: It is suitable for some scenarios with high requirements for response time and relatively few input and output points, such as small emergency shutdown systems, combustion management systems, etc. It has the characteristics of small size and fast processing speed, and can achieve a response time significantly lower than ten milliseconds.

Some product models of HIMA:

Input modules: F3221, F3222, F3223, F3224, F3236, F3237, F3238, F3240, F5203, F5220, F6208, F6214, F6215, F6216, F6216A, F6217, F6220, F6221, etc.

Output modules: F3322, F3330, F3331, F3332, F3333, F3334, F3348, F3422, F3430, F6705, F6706, etc.

Power supply modules: F7126, F7130A, F7131, F7133, etc.

Communication modules: F8621A, F8627X, etc.

CPU modules: F8650X, F8652X, etc.

Bus connection modules: H7505, H7506, etc.

Relay modules: H4116, H4122, H4135, H4136, H4135A, etc.

3005319639

3005319639