The MOOG Company was founded in the United States more than fifty years ago. It focuses on the field of precise motion control and is committed to manufacturing precision motion control products and systems. Its high-performance systems are widely used in a multitude of fields, including military and commercial aircraft, satellites, spacecraft, launch vehicles, missiles, as well as industrial machinery, wind energy equipment, marine engineering, and medical devices. From civil aircraft cockpits, wind turbines for power generation, Formula One racing cars to medical infusion systems, MOOG's motion control technology has been continuously enhancing the performance of related products.

The history of the MOOG Company can be traced back to its founder, William C. MOOG, a man who was not only an inventor and entrepreneur but also a visionary. In 1951, Bill MOOG successfully developed the electro-hydraulic servo valve, a device capable of converting weak electrical pulses into precise and powerful movements. In July of the same year, Bill MOOG, along with his brother Art and Lou Guyer, rented a corner of the abandoned Proner Airport in East Aurora, New York, and established the MOOG Valve Company.

In the energy sector, for gas, steam, and hydraulic turbines, MOOG provides electric and hydraulic solutions that can not only improve metering and positioning capabilities but also reduce system operating costs. Whether it is the control of inlet guide vanes, gaseous and liquid fuel control, process control, relief valve control, or fuel metering pumps, MOOG's technology is the ideal choice for customers in key power generation applications who pursue reliability and high performance. In the field of wind power generation, MOOG provides equipment manufacturers and operators with reliable solutions ranging from special products that optimize the performance of wind turbines to complete electric and hydraulic pitch control systems. Its slip ring products have a service life of over 100 million revolutions, and more than 7,500 PITCHmaster servo drives have been installed globally. These are strong proofs of MOOG's ability to meet the needs of the wind energy market.

Currently, MOOG's products are widely applied in China, covering industries such as injection molding, aerospace, steel, wind power generation, and gas and steam turbines. They are especially widely used in steel mills in northern China. For example, Wuhan Iron and Steel Corporation has adopted related products such as D136-001-007. The application fields of MOOG products also include metal forming machinery and plastic machinery in the industrial machinery sector, as well as metallurgical machinery, that is, various mechanical equipment used in the metallurgical industry for processes such as smelting, ingot casting, rolling, handling, and packaging. Today, MOOG's business spans across regions such as China, Europe, Southeast Asia, Japan, North America, and India. These regions are also the main exporting countries and regions of injection molding machines globally. With its own technological advantages and product performance, MOOG continues to exert a significant influence in the global market.

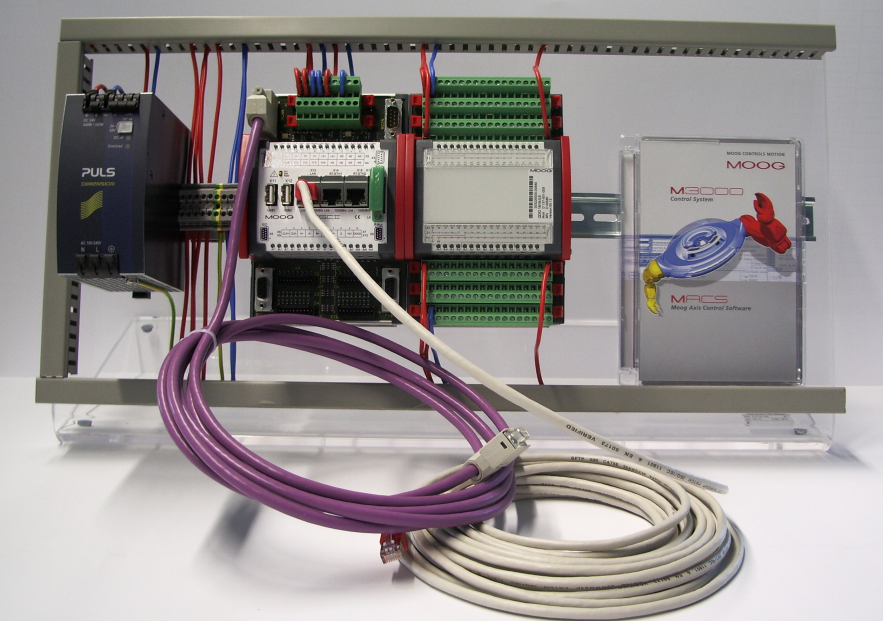

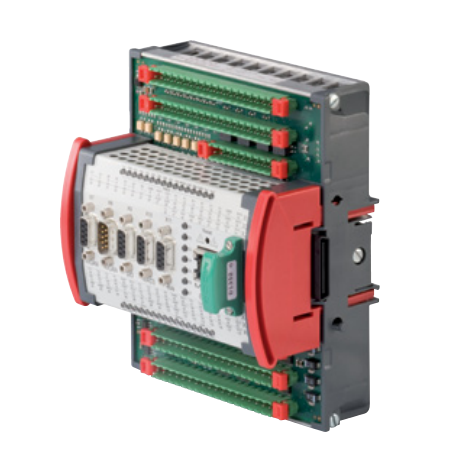

Some model numbers of MOOG controllers:

CPU modules

Ethernet modules

D136-002-002

D136-002-003

D136-002-004

D136-002-005

D137-001-010

Digital remote link modules

D137-002-001

Dongles

D138-002-001

D138-002-012

Integrated controllers

D136-003-001

D136-003-002

D136-003-004

D136-006-001

Touchscreens

D137-004-004

D137-004-005

D137-004-006

Operation panel rdisp22, Order number: D138-006-001

MSD servo controllers

G391-001-001

G391-001-002

G391-001-003

3005319639

3005319639