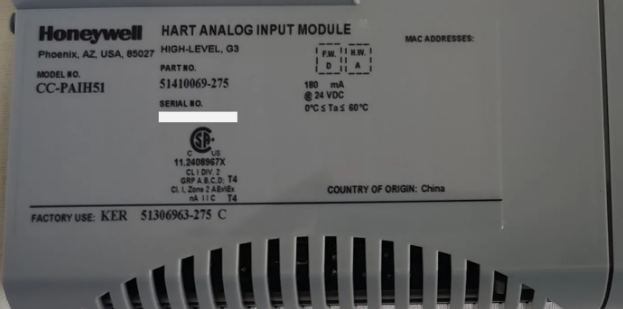

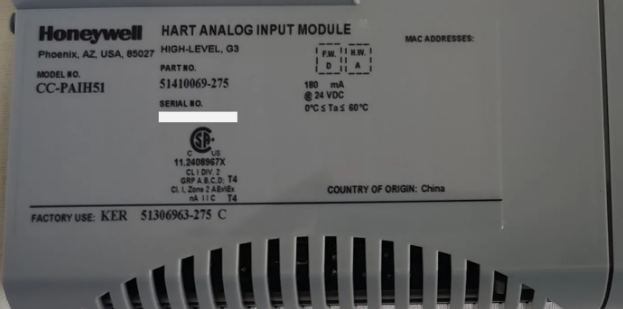

Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. Honeywell

CC-PAIH51 51410069-275 is a high-performance high-level

analog input module with HART communication function in the

C300 series, and it is a key component in industrial automation control systems. Developed and produced by Honeywell, a world-renowned automation technology enterprise, this product relies on the brand's decades of technical accumulation and innovation capabilities in the industrial control field. It can accurately collect high-level analog signals in industrial sites and realize two-way data transmission and equipment diagnosis through the HART protocol, providing reliable data support for enterprises' production process monitoring, equipment management and process optimization.

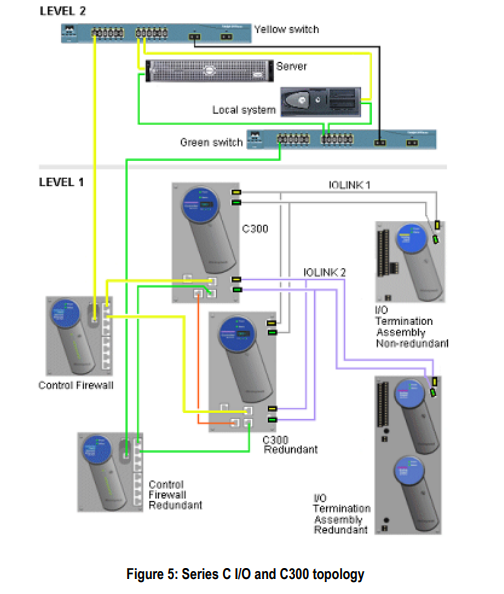

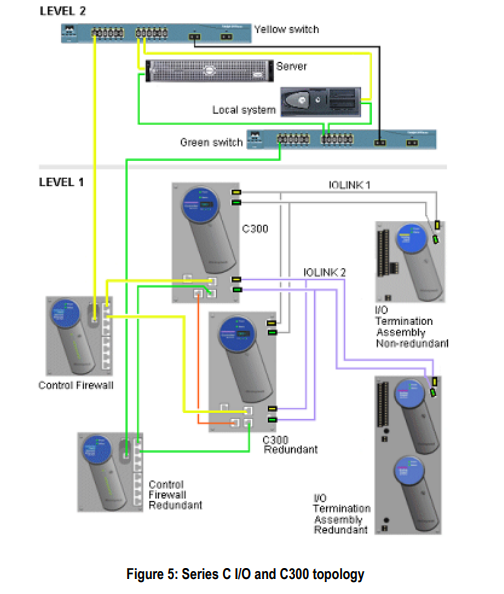

As an important part of the C300 series, this module can be seamlessly integrated into Honeywell's Experion PKS (Process Knowledge System), compatible with a variety of industrial standard signal types, and is suitable for petrochemical, electric power, metallurgy, pharmaceutical and many other industries that have high requirements for signal acquisition accuracy and system stability. It can not only obtain the analog signals from on-site sensors or transmitters in real time and accurately, but also remotely configure, calibrate and troubleshoot on-site equipment through the HART protocol, which greatly reduces on-site maintenance workload and improves the overall operation efficiency and reliability of the industrial control system.

Performance Parameters

Advantages and Features

High-Precision Signal Acquisition: Adopting a 16-bit high-resolution ADC (Analog-to-Digital Converter) and advanced signal filtering algorithms, the measurement accuracy can reach ±0.05% FS. It can accurately capture weak signal changes in industrial sites, providing accurate data basis for production process optimization and equipment fault early warning, and effectively avoiding production decision-making errors caused by signal acquisition errors.

HART Protocol Two-Way Communication: Supporting HART 7.0 protocol, it can not only collect analog signals from on-site equipment, but also send configuration commands to on-site transmitters through this protocol to realize remote calibration, parameter modification, equipment fault diagnosis and other functions. No need for staff to operate on-site, which greatly reduces maintenance costs and improves equipment management efficiency.

Multi-Channel and Multi-Signal Compatibility: With 8 independent input channels, it can collect a variety of industrial standard analog signals such as 4-20 mA DC and 0-10 V DC at the same time. The channel signal type can be flexibly configured through software without replacing hardware modules, adapting to the signal acquisition needs of different industrial scenarios, and reducing the enterprise's equipment procurement cost and inventory pressure.

Strong System Integration: As a Honeywell C300 series module, it can be seamlessly integrated into the Experion PKS Process Knowledge System, realizing efficient data interaction with components such as controllers, human-machine interfaces, and historical databases in the system. No additional interface development is required, simplifying the system construction process and improving the overall coordination and operation stability of the industrial control system.

Comprehensive Fault Diagnosis and Protection: Equipped with functions such as channel open-circuit detection, overcurrent protection, and signal over-range alarm, the module also has an internal fault self-diagnosis circuit, which can monitor the module's operating status in real time. Once a fault is detected, it immediately sends an alarm signal and uploads fault information, facilitating staff to quickly locate and solve problems, reducing the risk of system shutdown, and ensuring production continuity.

High Reliability and Environmental Adaptability: Complying with strict industrial electromagnetic compatibility standards and wide temperature operating range requirements, it can operate stably in complex industrial on-site environments such as electromagnetic interference and temperature fluctuations. The module adopts high-quality electronic components and rigorous circuit design, with a long Mean Time Between Failures (MTBF), providing a strong guarantee for the long-term and reliable operation of the industrial control system.

Application Fields

Petrochemical Industry: In the production processes of crude oil extraction, oil refining, and chemical synthesis, it can be used to collect analog signals from equipment such as pressure transmitters, level transmitters, and temperature transmitters (after signal conversion). It monitors key process parameters such as reactor pressure, storage tank level, and pipeline medium temperature in real time. Through the HART protocol, it can remotely calibrate transmitters, ensuring the safety, stability, and efficiency of the production process, and avoiding safety accidents or product quality problems caused by abnormal parameters.

Power Industry: Suitable for the monitoring of thermal systems and power generation systems in thermal power plants, hydropower plants, and nuclear power plants. It collects analog signals such as boiler steam pressure, turbine lubricating oil pressure, and generator stator temperature (after signal conversion), providing real-time data support for the normal operation of the unit. At the same time, the HART protocol enables remote diagnosis of on-site transmitter faults, reducing downtime for maintenance and ensuring continuous and stable power supply.

Metallurgical Industry: In the smelting process of iron and steel and non-ferrous metals, it is used to collect analog signals such as blast furnace gas pressure, converter temperature (through thermocouple signal conversion), and rolling mill hydraulic system pressure. It monitors smelting process parameters in real time to ensure that the smelting process meets quality standards. The HART protocol enables remote management of on-site detection equipment, improving equipment maintenance efficiency and reducing production interruptions caused by equipment failures.

Pharmaceutical Industry: In key links of pharmaceutical production such as fermentation, purification, and sterilization, it collects analog signals such as temperature, pressure in the reaction tank, and drug concentration (converted by dedicated sensors). It strictly controls production process parameters to ensure that drug quality meets GMP (Good Manufacturing Practice) requirements. The two-way communication function of the HART protocol enables precise calibration of on-site detection equipment, avoiding manual operation errors and improving the reliability and compliance of the production process.

Water Treatment Industry: Used for water quality monitoring and treatment process control in waterworks and sewage treatment plants. It collects analog signals such as water quality pH value (converted by transmitters), turbidity, and dissolved oxygen content, and monitors the status of the water treatment process in real time. Through the HART protocol, it remotely diagnoses on-site detection equipment, timely detects and solves equipment faults, ensures the water treatment effect, and meets environmental protection discharge or water supply quality standards.

Before installing the Honeywell CC-PAIH51 module, ensure that the power supply of the relevant control system is turned off to avoid electric shock hazards during operation or electrical damage to the module and other equipment. Meanwhile, prepare the tools required for installation, such as a screwdriver. Confirm that the installation space inside the control cabinet meets the module's size requirements and that there are no strong electromagnetic interference sources near the installation location to ensure the normal operation of the module.

Align the CC-PAIH51 module with the corresponding slot on the backplane of the C300 controller. Note that the interface direction of the module must completely match the direction of the backplane slot. Gently insert the module into the slot to ensure a tight and secure connection between the module and the backplane. Use a screwdriver to tighten the fixing screws between the module and the backplane. The tightness of the fixing screws should be moderate: if too loose, it may cause poor contact of the module, affecting signal transmission and power supply stability; if too tight, it may damage the threaded interfaces of the module or the backplane.

Select appropriate signal cables based on the type of sensors or transmitters used in the actual application scenario. For current signals (4 - 20 mA DC, 0 - 20 mA DC), connect the positive and negative poles of the cables to the corresponding terminal blocks of the module's input channels respectively, ensuring a secure connection to prevent signal loss or measurement errors due to poor contact. For voltage signals (0 - 10 V DC, 1 - 5 V DC), also connect them to the corresponding terminal blocks according to the correct polarity. During the connection process, pay attention to avoiding cross-interference between cables; wire troughs or cable ties can be used to organize and fix the cables.

If the system needs to communicate with on-site equipment via the HART protocol, connect the HART communication cable to the HART communication interface of the module. Ensure that the shielding layer of the communication cable is properly grounded to reduce the impact of electromagnetic interference on communication quality. The connection of communication cables should comply with relevant wiring specifications; avoid laying them in parallel with high-voltage cables to prevent signals from being affected by electromagnetic induction interference.

After completing all the above connection steps, recheck whether all cable connections are correct and secure. Once confirmed correct, turn on the power supply of the control system and observe the status of the indicator lights on the module. Under normal circumstances, the power indicator light of the module should be steadily on, indicating that the module is normally powered. At the same time, use system software or relevant monitoring tools to check whether the module can correctly identify the signals of each input channel and whether it can communicate normally with on-site equipment via the HART protocol. If abnormal indicator lights, failure to collect signals normally, communication faults, or other issues are found, immediately cut off the power supply and recheck the installation steps and cable connections.

Q1: When installing the Honeywell CC-PAIH51 module, if the module's power indicator does not light up, what might be the cause? How to troubleshoot it?

A1: A non-illuminated power indicator is usually related to power supply or hardware connection issues. Troubleshooting can be done by following these steps:

Check the power supply circuit: First, confirm whether the backplane of the C300 controller normally outputs a 5 V DC voltage (a multimeter can be used to measure the power supply terminals of the corresponding slot on the backplane). If the voltage is abnormal, check whether the controller's power module is faulty or if the power supply line is loose.

Recheck the module installation: After pulling out the module, check if the backplane slot has dust, deformed pins, or other issues. Clean the slot with a dry brush, then re-align the interface, insert the module back, and tighten the fixing screws to ensure tight contact between the module and the backplane.

Troubleshoot module hardware faults: If there are no problems with the above steps, the module can be replaced into another normally working slot on the C300 backplane for testing. If the indicator still does not light up, there may be an internal hardware fault in the module. Contact Honeywell after-sales service for repair or replacement.

Q2: The Honeywell CC-PAIH51 supports remote calibration via the HART protocol. What conditions need to be prepared in advance for actual operation? Will the calibration process affect on-site production?

A2: The following conditions must be met before remote calibration, and the calibration process basically does not affect production:

Preparations: ① Ensure the module has been properly connected to the Experion PKS system, and the HART communication cable is firmly connected with its shielding layer properly grounded; ② The on-site transmitter is in normal working condition, with no signal interruption or hardware failure; ③ Obtain the HART address and device model of the transmitter through system software (such as Honeywell Control Builder) and confirm that they match the communication parameters of the module.

Impact on production: Remote calibration adopts an "online non-interruptible signal" design. During the calibration process, the module will still continuously collect and transmit the analog signal (e.g., 4-20 mA) from the transmitter. Parameter synchronization is only performed at the moment the calibration command is sent, which will not cause signal loss or interruption in the production process. It is suitable for scenarios with high requirements for production continuity, such as the chemical and power industries.

Q3: Compared with similar analog input modules of the Siemens S7-1500 series, what are the main advantages of the Honeywell CC-PAIH51 in applications in the metallurgical industry?

A3: In the high-temperature and high-interference production environment of the metallurgical industry, the advantages of the CC-PAIH51 are mainly concentrated in the following two aspects:

Signal stability and accuracy: The measurement accuracy of the Siemens S7-1500 series analog modules is approximately ±0.1% FS, and their anti-electromagnetic interference capability relies on additional shielding measures. In contrast, the CC-PAIH51 has an accuracy of ±0.05% FS and a built-in anti-electromagnetic interference filter circuit, complying with the IEC 61000-6-2 industrial immunity standard. In scenarios with strong electromagnetic interference such as rolling mills and continuous casting machines, it can more stably collect hydraulic pressure and furnace temperature conversion signals, avoiding parameter fluctuations caused by interference.

System integration and maintenance efficiency: Siemens modules need to be integrated with the PLC system via the Profinet protocol. If connecting to a third-party metallurgical production management platform, additional interfaces need to be developed. However, the CC-PAIH51 is seamlessly integrated with the Experion PKS system, allowing direct access to functions such as fault diagnosis and historical data query within the platform. Moreover, through the HART protocol, it can remotely calibrate blast furnace gas pressure transmitters, eliminating the need for staff to enter high-temperature on-site areas, which improves maintenance efficiency by more than 40%.

Q4: Do the 8 independent channels of the Honeywell CC-PAIH51 support simultaneous collection of different types of signals? For example, some channels collect current signals and some collect voltage signals. What should be noted during configuration?

A4: The 8 channels support simultaneous collection of different types of signals. The following two points should be noted during configuration:

Software configuration logic: Enter the module configuration interface through the Honeywell Control Builder software. Each channel can independently select the signal type (4-20 mA DC/0-20 mA DC/0-10 V DC/1-5 V DC) without relying on hardware jumpers. After configuration, click "Download to Module" to take effect. The operation is flexible and no power-off is required.

Wiring specifications: Current signals (e.g., output from transmitters) need to be connected to the "+" and "-" terminals of the module, and the loop impedance must be ≤250 Ω. For voltage signals, attention should be paid to the input range to avoid exceeding the rated values of 0-10 V DC or 1-5 V DC. At the same time, separate the signal cables from high-voltage cables (such as motor power cables) during laying to reduce measurement errors caused by voltage drop or interference. For example, in the water treatment industry, 4 channels can be used to collect 4-20 mA signals from pH transmitters, and 4 channels to collect 0-10 V signals from turbidity sensors, meeting the demand for simultaneous monitoring of multiple parameters.

Q5: If the on-site equipment only supports HART 5.0 or 6.0 protocols, can the Honeywell CC-PAIH51 (which supports HART 7.0) be compatible for communication? Is additional equipment upgrade required?

A5: Full compatibility is achieved, and no on-site equipment upgrade is needed. The specific reasons are as follows:

The HART protocol adopts a "backward compatibility" design, and the HART 7.0 version can automatically identify and adapt to on-site equipment with HART 5.0/6.0 versions (such as pressure and level transmitters). During actual communication, the CC-PAIH51 first sends a protocol version detection command and automatically adjusts communication parameters based on the device's feedback to ensure normal two-way data transmission. For example, in the pharmaceutical industry, if there are still some HART 5.0 version temperature transmitters on-site, the module can normally collect their analog signals and realize remote status query (such as device power supply and fault codes) through simplified HART commands. Only some new functions added in HART 7.0 (such as multi-variable data transmission) cannot be used, but this does not affect core monitoring and maintenance needs, reducing the enterprise's equipment upgrade costs.

Customers who purchased this product are also browsing the following products:

Honeywell LCNP4E 51405098-100 Interface Card

Honeywell CC-PAIH01 51405038-175 Hart analog input module

GE IS200DTAIH1ABB Mark VI printed circuit board

Woodward 8273-140 2301D Load Sharing Speed Control

3005319639

3005319639