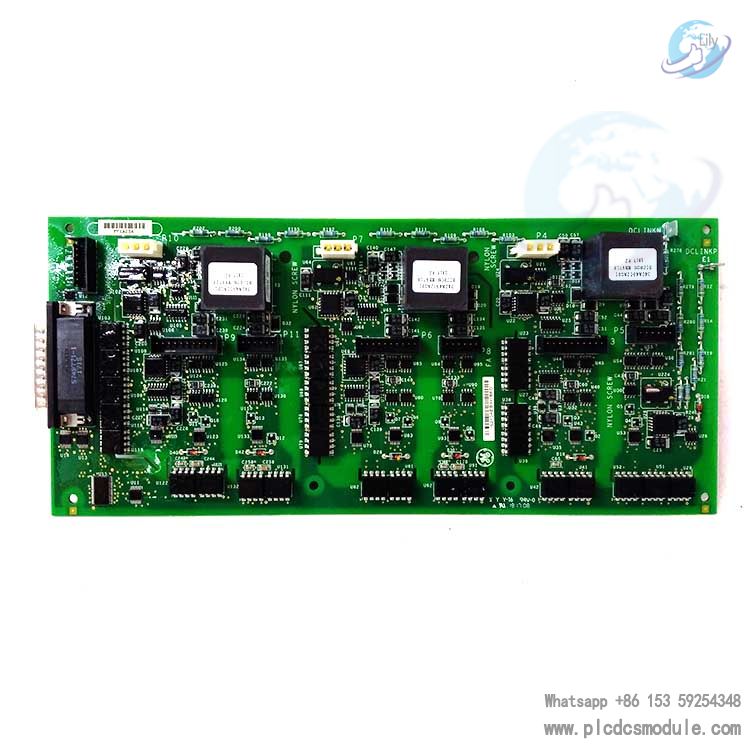

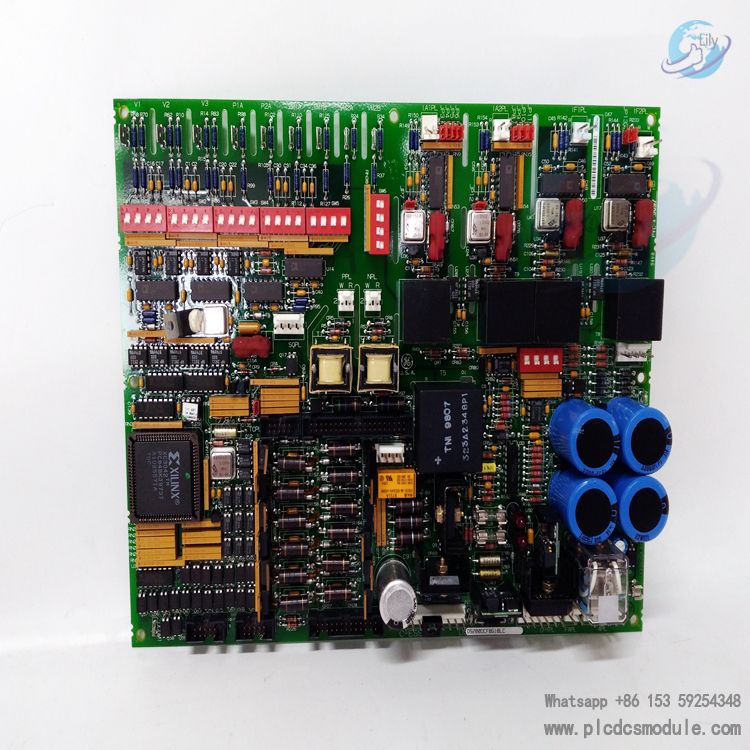

The GE WES5120 2340-21006 Field Controller Master Unit Module is a key component of industrial automation control systems. Equipped with abundant analog and digital input/output interfaces, it enables precise signal acquisition and control. Supporting multiple communication protocols, it ensures efficient inter-device communication. With a wide operating temperature range, it adapts to harsh environments. Its modular design facilitates maintenance and replacement, ensuring stable system operation, widely used in industrial automation, energy management and other fields.

Functional Features

Control Core Function:As the main unit module of the field controller, GE WES5120 2340-21006 serves as the core of the entire control system, coordinating and managing the operation of field devices. It receives signals from various sensors, processes and analyzes data, and sends control commands to actuators based on preset strategies to achieve precise control over industrial processes and environmental parameters.

Communication Function:Supports multiple communication protocols for inter-device communication, including upper computers (e.g., monitoring computers, DCS) to upload field data and receive control commands, as well as intelligent field devices (e.g., smart instruments, PLCs) for collaborative operation.

Data Processing Capability:Features robust real-time data processing for massive field data, including filtering/converting/normalizing analog signals from sensors, logical judgment and status monitoring for digital signals, and simple calculations (e.g., averages, max/min values) to facilitate control decision-making.

Technical Parameters

I/O Interfaces

Equipped with diverse I/O interfaces to meet field device connection needs:

Analog Input (AI): 16-bit+ resolution for temperature/pressure/flow sensors;

Digital Input (DI): For device status signals (start/stop, valve position);

Analog Output (AO): For control valves and frequency converters;

Digital Output (DO): For relays and contactors to enable start/stop control.

Power Requirements

Requires stable DC power (typically 24VDC) with a wide voltage range and protection functions (overvoltage/overcurrent/reverse connection) for safe operation under abnormal power conditions.

Operating Temperature Range

Designed for harsh industrial environments, with a wide range (e.g., -40℃ to 85℃) to ensure stable performance in extreme temperatures.

Application Scenarios

Industrial Automation:Applied to control various industrial production processes, such as reactor control in chemical production, manufacturing equipment control in pharmaceutical industry, and production line control in automotive manufacturing. It realizes automation and intelligence of production processes through precise field device control, improving production efficiency and product quality.

Energy Management Systems:Used in monitoring and controlling production, transmission, and distribution of energy (electricity, water, gas, etc.). For example, it monitors and controls power equipment in substations to ensure stable power system operation, and optimizes heating/water supply systems to enhance energy efficiency.

Intelligent Building:Applied to environmental control, security systems, and lighting systems in intelligent buildings. For instance, it connects with temperature/humidity/air quality sensors to realize real-time monitoring and automatic adjustment of indoor environmental parameters, and collaborates with access control systems and surveillance cameras to enhance building security.

Customers who purchased this product are also browsing the following products:

GE WES5120 5120-1106 Field controller master unit

GE IS420UCSCH1A-F-V0.1-A Mark VIe Controller

honeywell SIEGER 05701-A-0511 16-Way Rear Access Rack

Emerson Ovation 5X00594G01 Analog Input Module

UNIOP ETT-VGA-0045 Touch Screen Panel | HMI Touch Screen

3005319639

3005319639