Extreme Environment Adaptability: Specifically designed for industrial environments, it can operate stably under extreme conditions such as temperature extremes, humidity changes, and vibrations. For instance, in high-temperature steel smelting workshops, humid chemical production areas, or mining sites with frequent vibrations, it can ensure the reliability and continuity of network connections, effectively reducing network failures caused by environmental factors and providing solid support for the stable operation of industrial production.

Robust and Durable Construction: Adopting a sturdy casing and high-quality internal components, it features shock resistance, dustproof, and other properties. Its protection level complies with industrial standards, which can effectively block the intrusion of dust and foreign objects, greatly extending the service life of the equipment and ensuring long-term stable operation even in harsh industrial environments.

Data Forwarding Capability

As an unmanaged switch, it does not have complex management functions such as VLAN (Virtual Local Area Network) and QoS (Quality of Service), but focuses on providing basic and reliable data forwarding capabilities. Through an efficient data forwarding mechanism, it can quickly and accurately transmit data packets from one port to the target port, ensuring the smooth transmission of network data, maintaining network stability and reliability, and providing strong support for data interaction in industrial automation systems.

Easy Deployment

In industrial network deployment, replacing proprietary networks with Ethernet LAN and PACSystems Ethernet switches can significantly simplify the network deployment process. GE SLN080 IC086SLN080 - A follows the plug-and-play principle. Simply connect the equipment and network cables, and the switch can automatically identify and configure port parameters, quickly putting it into operation. This not only reduces the difficulty and time cost of deployment but also improves network reliability, enabling industrial enterprises to build and expand networks more efficiently.

Application Areas

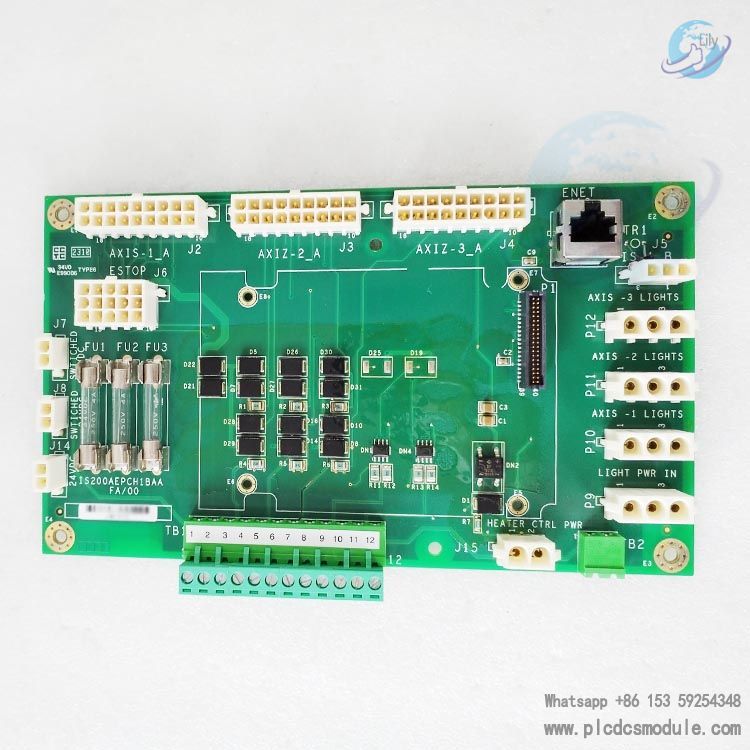

Factory Automation: In factory automation production lines, it plays a key role in connecting various automation devices, such as PLC (Programmable Logic Controller), sensors, and actuators. By ensuring real - time and stable data transmission between devices, it helps the production process achieve precise control and efficient collaboration, thereby improving production efficiency and product quality.

Production Line Control: For the control and monitoring systems of production lines, this switch ensures the timely delivery of control commands and the rapid feedback of device operating status data. Engineers can monitor the operation of the production line in real - time through the network, promptly detect and solve problems, and ensure the smooth operation of the production line.

Industrial Robot Communication: In the application scenarios of industrial robots, it builds a reliable communication link between robots, control systems, and other devices. It can meet the strict requirements of robots for low - latency and high - bandwidth data transmission, enabling robots to perform tasks accurately and enhancing the flexibility and intelligence level of industrial automation production.

Customers who purchased this product are also browsing the following products:

GE IS200TBCIS2CCD Mark VI Turbine Control PCB Module

GE DS200ADPBG1ABB Genius I/O Adapter Board

HIMA 80105 984080105 COMMUNICATION MODULE

Foxboro P0916AA Field terminal component

3005319639

3005319639