Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. The

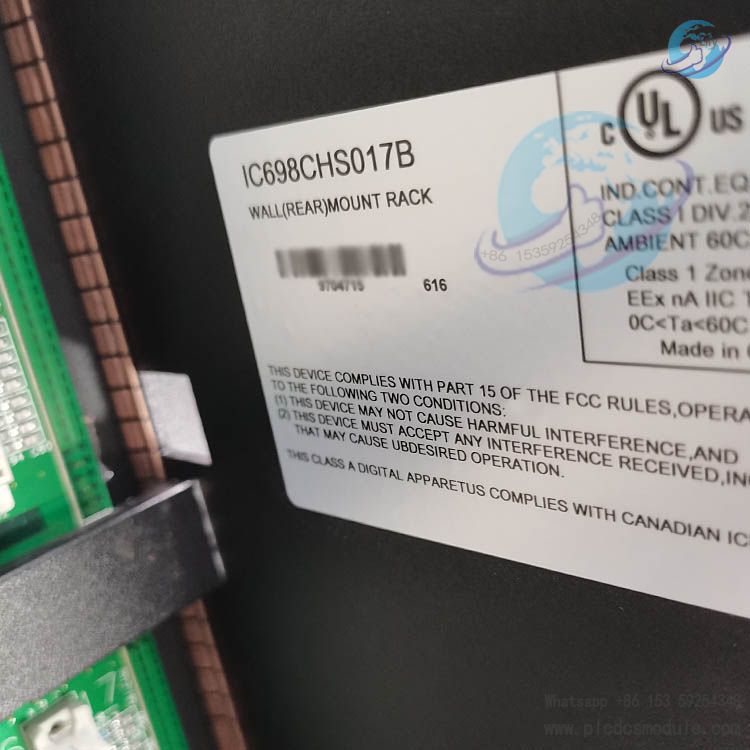

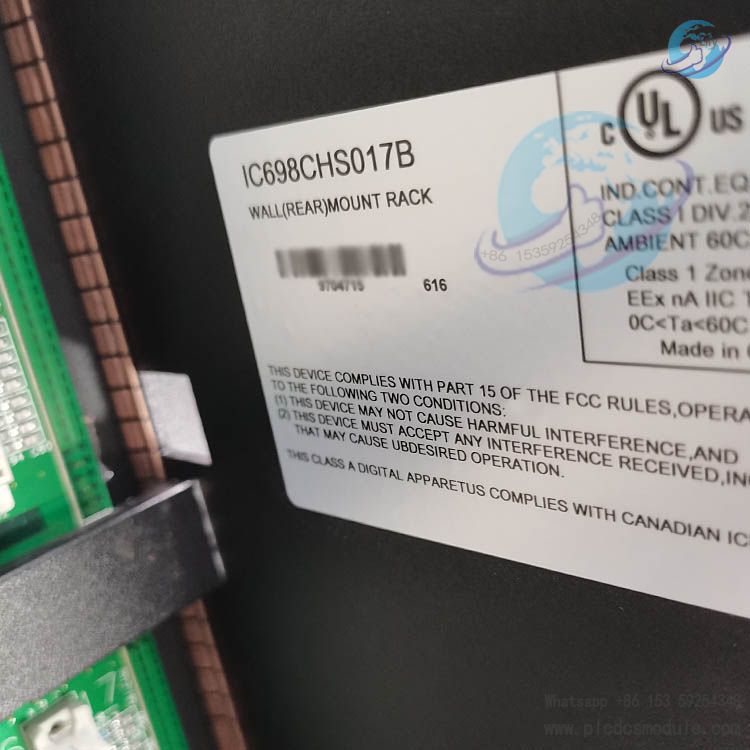

IC698CHS017B is a dedicated wall-mounted (rear) mounting

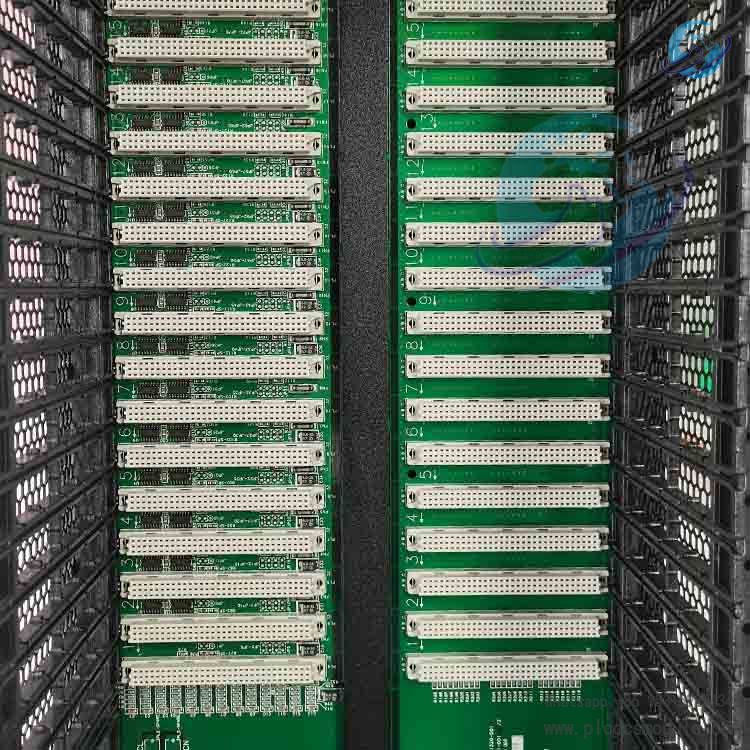

rack developed by GE Intelligent Platforms (now part of Emerson) , specifically designed for the PACSystems RX7i industrial control system. It provides a secure and space-saving installation solution for RX7i Central Processing Units (CPUs) (such as models IC698CPE010/CPE020) , Input/Output (I/O) modules, power supplies, and auxiliary components (including fan trays and battery modules) .

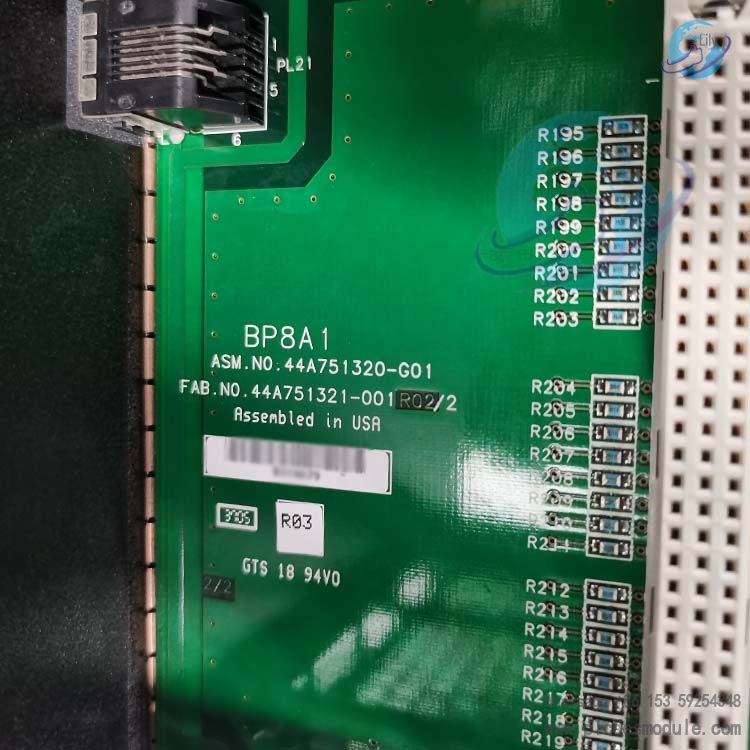

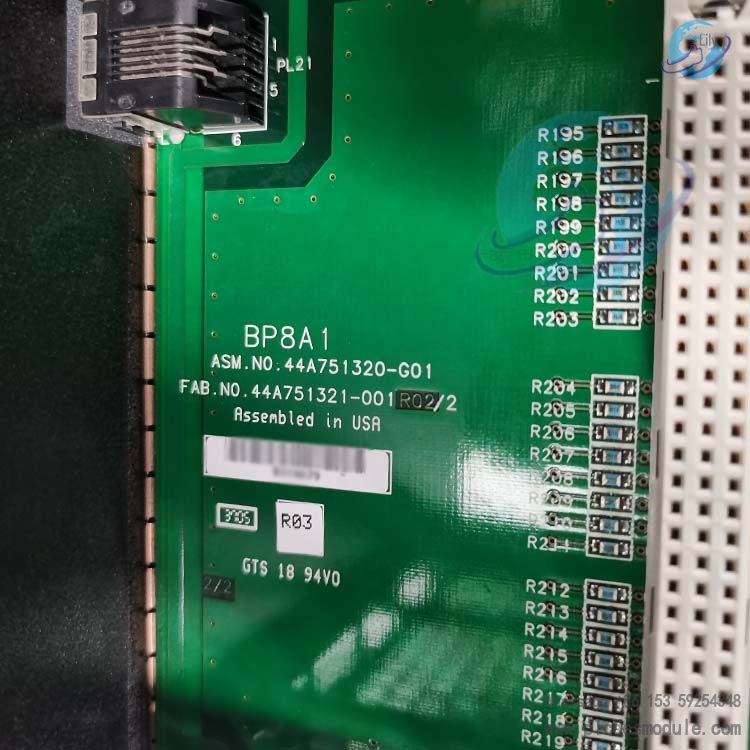

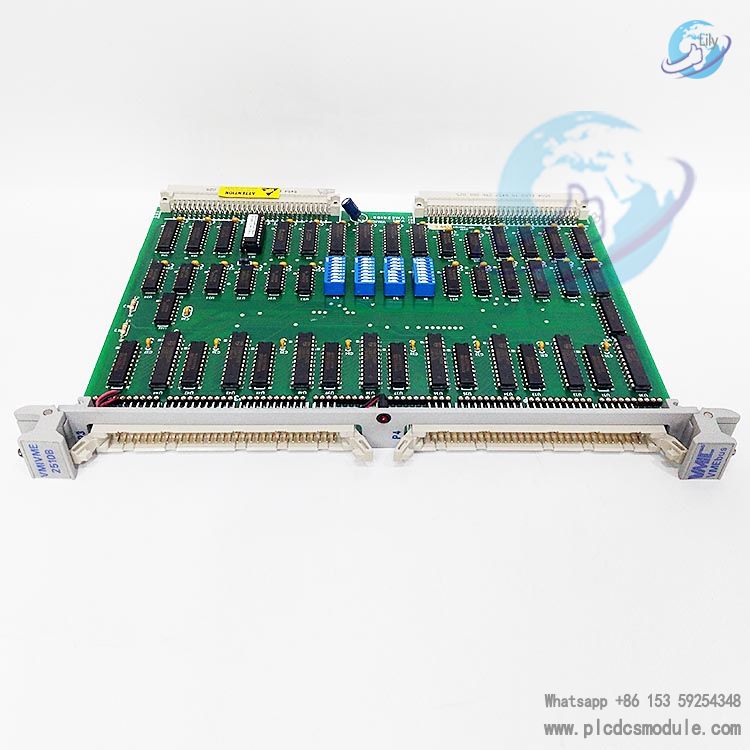

This rack is engineered to meet the characteristics of industrial environments, featuring a robust steel structure and a rear-mount design. This design not only optimizes floor space utilization but also enables flexible installation in control rooms, on-site equipment cabinets, or narrow industrial areas. It complies with the VME64 standard (i.e., ANSI/VITA 1 standard) , ensuring seamless compatibility with all RX7i system modules. Additionally, it supports organized cable management and efficient heat dissipation. Whether for the deployment of a new RX7i system or the expansion and upgrade of an existing system, the IC698CHS017B can serve as a reliable foundational component, facilitating the construction of a stable and scalable industrial control architecture.

Unlike traditional floor-mounted racks, the rear-mount structure of the IC698CHS017B maximizes the available space in control rooms and narrow on-site areas. It can be installed closely against walls or the rear of equipment cabinets, reducing the floor space footprint by up to 60% compared to floor-mounted racks — a critical advantage for facilities with limited space, such as small production units and offshore platforms.

Constructed from 14-gauge cold-rolled steel with a powder-coated surface, it offers scratch resistance, corrosion resistance, and tolerance to mechanical impacts. Compliant with the ASTM B117 salt spray standard (48 hours) and capable of operating within a wide temperature range (-10°C ~ +55°C), it ensures long-term reliable operation in harsh industrial environments, such as oil refineries and coastal power plants.

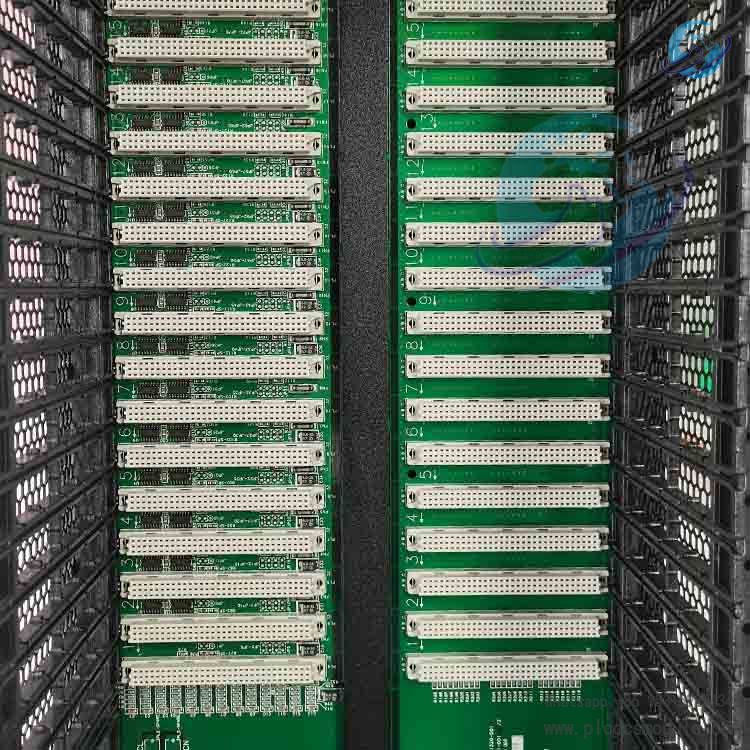

Exclusively designed for the PACSystems RX7i ecosystem, the rack’s dimensions, slot spacing, and backplane adaptability are precisely matched to RX7i modules. It supports all RX7i components (central processing units, I/O modules, power supplies) without modification, eliminating compatibility risks and simplifying system design. This "plug-and-play" integration method reduces installation time by 30% compared to universal racks.

The open rear structure facilitates air circulation around RX7i modules. When used in conjunction with fan trays (e.g., IC697ACC721), it prevents module overheating. The ventilation gap between the rack and the wall effectively expels hot air, ensuring that the operating temperature of modules remains within a safe range.

Integrated rear cable channels and retaining clips organize power cables, Ethernet cables, and serial cables, preventing cable tangling and simplifying troubleshooting. Labeled cable ports also enable quick identification of connections, reducing maintenance time.

The 10U-high rack can accommodate up to 10 RX7i modules (or a combination of modules and auxiliary components). Its stackable design allows vertical expansion (with multiple racks installed in sequence) to adapt to larger-scale systems. The included stainless steel mounting hardware ensures secure installation of the rack on concrete walls, drywall, or metal walls, making it suitable for the layout requirements of different facilities.

Suitable for control rooms in manufacturing plants (automotive, electronics, food and beverage industries) where space optimization is highly required. The rear-mount design allows the rack to be installed close to the wall, freeing up floor space for operators to move around and place other equipment. It can safely house RX7i central processing units and I/O modules that control production lines, facilitating access to modules during maintenance while keeping the work area neat and organized.

Used in sheltered on-site environments (such as oil and gas wellheads, power plant turbine rooms, and sewage treatment plants). Its robust steel structure and wide temperature tolerance range (-10°C ~ +55°C) can cope with harsh on-site conditions, and the wall-mounted design eliminates the need for floor-mounted racks — which is crucial in narrow spaces (such as small equipment sheds and offshore platforms).

Applicable to wind farms, solar power stations, and battery energy storage systems (BESS). The rack can be stably installed on the rear wall of control cabinets, accommodating RX7i modules used to monitor and control renewable energy equipment (such as wind turbine converters and photovoltaic inverters). Its corrosion resistance (48-hour salt spray resistance) enables it to function normally in coastal wind farms or outdoor solar facilities with mild environmental exposure.

It is a key component for upgrading old industrial control systems to RX7i systems. It allows new RX7i modules to be seamlessly integrated into existing facilities, and the rear-mount design does not interfere with the current floor layout. For example, when upgrading a Series 90-70 system to an RX7i system in a chemical plant, the IC698CHS017B can serve as a "plug-and-play" installation solution, perfectly adapting to the existing wall infrastructure.

Customers who purchased this product are also browsing the following products:

GE IC698CPE020-JX Central Processing Unit

GE IS200DTAIH1ABB Mark VI printed circuit board

ABB PDD405A101 3BHE041626R0101 control hub

Honeywell LCNP4E 51405098-100 Interface Card

3005319639

3005319639