Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. The ABB

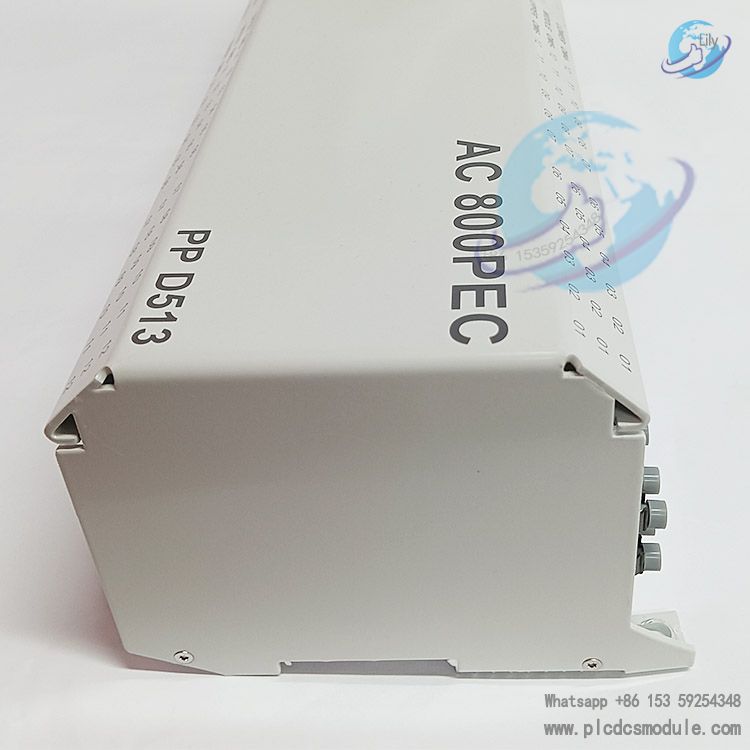

PPD513A0E-110110 3BHE039724R0E41 is a high-performance

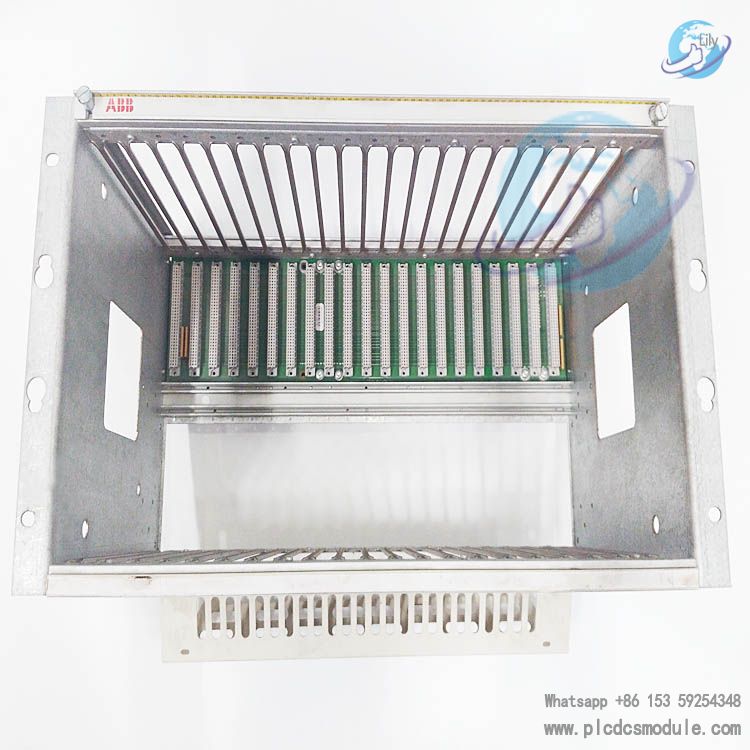

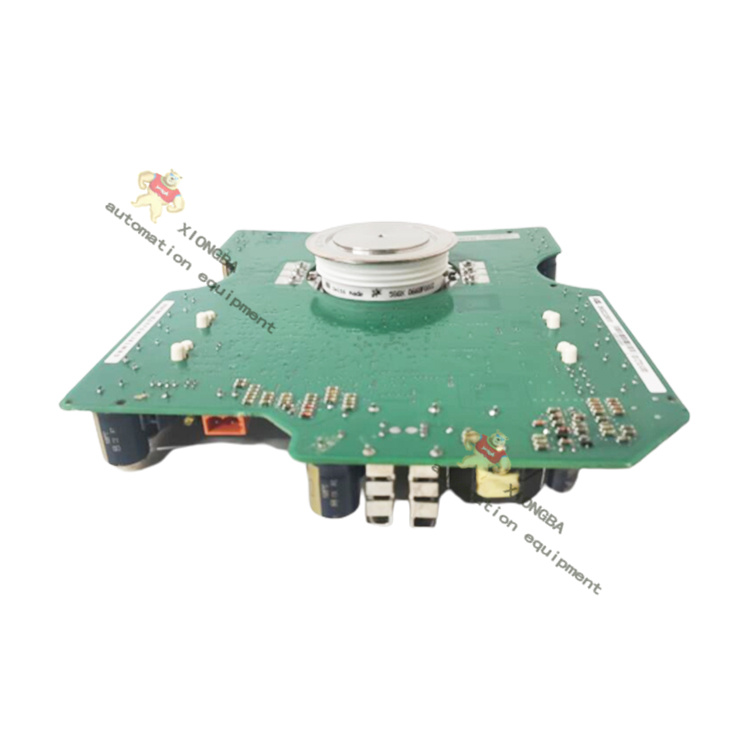

AC 800PEC Controller (Process Equipment Controller) designed for precision industrial process control and critical equipment regulation. As a core component of ABB AC 800 series automation platform, it integrates advanced control algorithms, multi-channel I/O processing, and robust communication capabilities, tailored for scenarios requiring high real-time performance, reliability, and scalability—such as power generation, oil & gas, and chemical processing.

Unlike standard PLCs, the AC 800PEC Controller focuses on equipment-specific control tasks (e.g., turbine speed regulation, boiler water level control, and motor drive synchronization). It supports seamless integration with ABB’s distributed control system (DCS) and third-party industrial devices, leveraging a modular hardware design and configurable software to adapt to diverse process requirements. With compliance to IEC 61508 (SIL 2) safety standards and industrial-grade environmental tolerance, it ensures stable operation in harsh industrial environments, making it a key solution for optimizing process efficiency and ensuring production safety.

Technical Specifications

2.1 Core Processing & Memory

2.2 I/O Interfaces & Communication

2.3 Power & Environmental Requirements

2.4 Mechanical Dimensions

Key Advantages

3.1 High Real-Time Performance & Precision Control

- 1 ms Minimum Control Cycle: Enables ultra-fast response to dynamic process changes (e.g., turbine speed fluctuations, chemical reaction deviations), ensuring process stability and product quality.

- 16-Bit I/O Resolution: Provides high-precision measurement and control (e.g., 0.01% full-scale accuracy for analog inputs), critical for applications like semiconductor manufacturing and laboratory-scale processes.

3.2 Robust Reliability & Safety Compliance

- Redundant Design: Supports dual power input (auto-switching) and flash memory backup (program and data redundancy), minimizing downtime due to hardware failures.

- SIL 2 Certification: Complies with IEC 61508 SIL 2, making it suitable for safety-related applications (e.g., emergency shutdown systems in oil refineries, turbine overspeed protection).

- Industrial-Grade Durability: Withstands -25°C ~ +70°C temperatures, vibration, and electromagnetic interference, ensuring stable operation in harsh environments (e.g., power plant turbine halls, outdoor wind farms).

3.3 Flexible Integration & Scalability

- Multi-Protocol Support: Compatible with PROFINET IRT, PROFIBUS DP, and Modbus, enabling seamless integration with ABB DCS (e.g., 800xA) and third-party devices (e.g., Siemens VFDs, Rockwell I/O modules).

- Modular I/O Expansion: Supports up to 32 expansion modules via PROFINET IRT, allowing users to scale I/O capacity from 8 AI/4 AO to 256 AI/256 AO without replacing the controller—ideal for growing production lines.

3.4 User-Friendly Programming & Maintenance

- ABB Control Builder M: Intuitive software platform for programming (IEC 61131-3 languages) and configuration. Supports offline simulation to test control logic before deployment, reducing on-site debugging time.

- Remote Monitoring & Diagnostics: Enables remote access via Ethernet/IP for real-time status checks, firmware updates, and fault diagnosis. Built-in self-diagnostic functions (e.g., I/O channel testing, communication link monitoring) alert users to potential issues before they cause downtime.

Application Fields

The ABB PPD513A0E-110110 AC 800PEC Controller excels in precision process control and critical equipment management across industries. Key application areas include:

4.1 Power Generation

- Thermal Power Plants: Used for boiler combustion control (regulating fuel flow, air supply, and steam pressure) and turbine speed synchronization (maintaining 3000 RPM for 50 Hz grids). It processes data from pressure, temperature, and flow sensors in real time, ensuring efficient power generation and compliance with grid frequency standards.

- Renewable Energy: Deployed in wind turbine control systems (adjusting blade pitch to optimize power output based on wind speed) and solar inverter management (coordinating battery storage and grid integration). Its wide-temperature design withstands outdoor wind farm and desert solar plant environments.

4.2 Oil & Gas

- Upstream Drilling: Controls drilling rig equipment (e.g., mud pump pressure, drill bit speed) to ensure safe and efficient wellbore construction. It communicates with downhole sensors via Modbus-RTU, providing real-time feedback on formation pressure and drill bit status.

- Downstream Refining: Regulates distillation columns (controlling temperature gradients and liquid levels) and catalytic crackers (maintaining optimal reaction conditions). Its SIL 2 certification ensures compliance with safety standards for flammable and explosive environments.

4.3 Chemical & Petrochemical

- Batch Processing: Manages batch reactors (e.g., pharmaceutical, polymer production) by controlling temperature, pressure, and reagent addition rates. Supports SFC (Sequential Function Chart) programming to automate multi-step batch sequences, reducing human error and ensuring product consistency.

- Continuous Processes: Controls chemical pipelines (flow rate, valve positioning) and wastewater treatment systems (pH adjustment, sludge separation). Its PROFINET IRT communication enables fast coordination with variable frequency drives (VFDs) and pumps.

4.4 Manufacturing & Automation

- Automotive Assembly: Regulates robotic welding systems (controlling current, voltage, and weld time) and paint booth temperature/humidity. Ensures consistent product quality and compliance with automotive industry standards (e.g., ISO/TS 16949).

- Semiconductor Fabrication: Controls cleanroom environmental parameters (temperature ±0.1°C, humidity ±2%) and wafer processing equipment (e.g., etching machine pressure). Its high-precision analog I/O (16-bit resolution) and low latency (1 ms control cycle) meet the strict requirements of semiconductor manufacturing.

Customers who purchased this product are also browsing the following products:

ABB SPAD346C3 Stabilized Differential Relay

ABB PPD512A10-150000 3BHE040375R1023 AC 800PEC Excitation Control

GE FANUC IS200AEADH1AAA Control Circuit Board

HONEYWELL 05701-A-0550 Controller

3005319639

3005319639