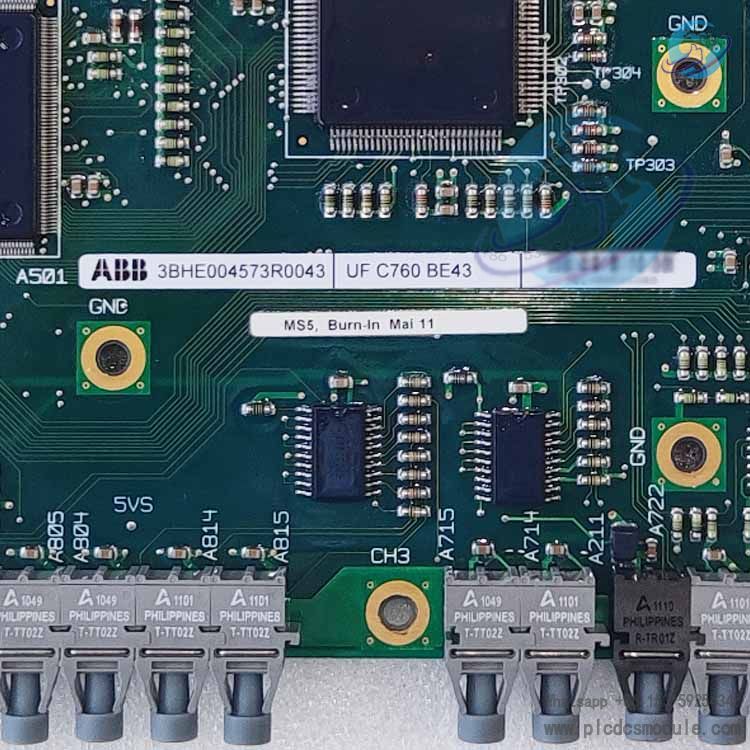

As a key model in ABB industrial control signal component lineup, the UFC760BE43 (Product ID: 3BHE004573R0043) is engineered as a dedicated "Main Circuit Interface" to bridge critical gaps between industrial main circuit equipment and control systems. Each unit features a net weight of 0.42 kg and follows ABB’s standard board dimensions (140 mm × 100 mm × 25 mm), ensuring seamless compatibility with 35 mm DIN rail installations— the industry’s most common setup for control cabinet integration. Sourced from ABB’s trusted manufacturing hubs in Switzerland (CH) and the United States (US), it meets global compliance standards for major industrial regions, making it a reliable choice for international projects. Unlike generic interface boards limited to basic "general signal conversion," this model specializes in exclusive industrial main circuit adaptation: it boosts main circuit signal anti-interference performance and optimizes compatibility with ABB equipment communication protocols, enabling precise collection of key parameters and real-time, secure transmission of control commands. Whether paired with frequency converter main circuits, power distribution main circuits, or other industrial core equipment, the ABB UFC760BE43 delivers stable, mission-critical signal support to keep industrial systems running smoothly.

The specific technical details of the 3BHE004573R0043 (ABB UFC760BE43) are as follows:

1. Signal Processing Capability

Analog Signals:

4-channel Analog Input (AI): Supports DC 0~10V / DC 4~20mA signals, equipped with a 16-bit high-precision ADC chip. The acquisition accuracy reaches ±0.1% Full Scale (FS), and it features automatic temperature drift compensation (temperature drift ≤0.01% FS/℃ within -20℃~+60℃). This enables precise capture of minor parameter fluctuations in the main circuit (e.g., 0.1A-level changes in frequency converter output current).

2-channel Analog Output (AO): Also supports DC 0~10V / DC 4~20mA, with an output impedance ≤1Ω and a load driving capacity of 500Ω, compatible with most industrial actuators.

Digital Signals:

8-channel Digital Input (DI): Compatible with both PNP and NPN polarities, with a response time ≤1ms. It supports software-adjustable signal filtering time (0.1ms~10ms), which effectively filters signal jitter caused by electromagnetic interference in the main circuit.

4-channel Digital Output (DO): Features relay contact output, with a contact rating of AC 250V/5A and DC 30V/5A. It boasts high durability with a mechanical lifespan of 1 million cycles and an electrical lifespan of 100,000 cycles, meeting the switching control needs of main circuit equipment.

2. Communication Protocols & Interaction Efficiency

Ethernet Interface: 1 Gigabit auto-negotiation Ethernet port (compatible with 10/100/1000Mbps) that supports the Profinet IRT (Isochronous Real-Time) protocol. The communication cycle can be as low as 1ms, satisfying the real-time transmission requirements of main circuit control commands.

RS485 Interface: 1 isolated RS485 port that supports the Modbus RTU protocol. The baud rate ranges from 1200 to 115200bps, and the data bits, stop bits, and parity mode can be configured via software. The maximum communication distance is 1200m (with a terminal matching resistor), making it suitable for signal interaction with long-distance main circuit equipment (e.g., remote water pumps in workshops).

3. Environmental & Safety Adaptability

Environmental Resilience:

Operating temperature range: -20℃~+60℃; passed 50 cycles of thermal shock testing (-40℃~+85℃). It can operate stably in high-temperature, high-humidity (5%~95% relative humidity, non-condensing) and dusty environments (IP20 protection, suitable for control cabinet installation).

Electromagnetic Compatibility (EMC): Compliant with EN 61000-6-2 (industrial immunity) and EN 61000-6-4 (industrial emission) standards, capable of resisting electromagnetic radiation interference from high-power main circuit equipment (e.g., frequency converters, motors).

Safety Design:

Beyond conventional overvoltage protection (activation above DC 36V), overcurrent protection (activation at output ≥10A), and short-circuit protection, it also features main circuit signal isolation (isolation voltage of 2500Vrms between analog/digital inputs and the board’s core circuit). This prevents high-voltage intrusion from the main circuit into the control system, ensuring equipment and personnel safety.

4. Power Consumption & Reliability

Power Requirements: Rated supply voltage of DC 24V (allowing ±15% fluctuation). Typical operating power consumption is ≤8W, and maximum power consumption is ≤10W, imposing low load requirements on the control cabinet’s power system.

Durability: Adopts industrial-grade FR4 PCB boards (temperature resistance grade: 130℃) and automotive-grade components. Third-party testing shows its Mean Time Between Failures (MTBF) reaches 120,000 hours, far exceeding the industry average of 80,000 hours for similar products.

Core Competitive Advantages

Compared with ordinary industrial interface boards on the market (such as third-party brand Y and ABB’s basic model UFC760AE41), the core advantage of this product lies in its "main circuit-specific design", with specific differences as follows:

1. Stronger Main Circuit Signal Processing Capability

Ordinary interface boards typically have an analog acquisition accuracy of ±0.2% FS and lack temperature drift compensation. In scenarios where the main circuit temperature fluctuates significantly (e.g., 40℃~60℃ inside frequency converter cabinets), the acquisition error can increase to ±0.5% FS, failing to meet the demand for precise main circuit parameter monitoring. In contrast, this product—with its ±0.1% FS accuracy and temperature drift compensation design—ensures that the acquisition error remains ≤±0.15% FS even when temperature changes. Additionally, ordinary interface boards do not have main circuit signal isolation, so high-voltage intrusion from the main circuit may damage the control system; this product’s 2500Vrms isolation voltage completely eliminates this risk.

2. Superior Compatibility with ABB Equipment Protocols

When third-party interface boards communicate with ABB ACS880 frequency converters or AC 800M controllers, a protocol converter (e.g., Profinet to Modbus) is required, which increases communication latency to over 20ms—unable to meet the real-time control needs of the main circuit. This product natively supports ABB’s dedicated communication protocols (such as Profinet IRT and ABB Drives protocol), enabling direct communication with ABB equipment with a latency of ≤5ms. At the same time, it supports one-click parameter configuration via ABB Control Builder software, eliminating the need for manual register address debugging and reducing integration time (from 2 days for ordinary products to 4 hours).

3. More Comprehensive Main Circuit Safety Protection

Ordinary interface boards only provide basic overvoltage and overcurrent protection, without main circuit fault isolation. When this product detects an abnormal main circuit signal (e.g., input voltage ≥DC 36V), it not only cuts off the board’s output but also sends a fault alarm signal to the control system and locks the board’s output (manual reset required), preventing equipment misoperation after fault recovery. Furthermore, the high durability of its relay output contacts (100,000-cycle electrical lifespan) can meet the frequent start-stop demands of main circuit equipment (e.g., 100 starts/stops per day, resulting in a service life of up to 27 years), while ordinary interface boards have a relay lifespan of only 50,000 cycles, with a service life of less than 14 years.

4. Higher Maintenance Convenience

This product is equipped with dedicated status indicators (e.g., "Main Circuit OK" for normal main circuit signals, "Isolation Fault" for isolation failures), which differ from the general-purpose indicators of ordinary interface boards. Maintenance personnel can directly judge the main circuit signal status through these indicators without connecting software for troubleshooting. It also supports reading historical fault records (up to 100 recent records) via the ABB Service Port (a hidden USB port on the side of the board), enabling quick identification of fault causes (e.g., a main circuit overcurrent event 3 days ago). In contrast, ordinary interface boards require removal and connection to a computer to read fault data, resulting in low maintenance efficiency.

Common Problems

1、Q: After connecting to the ACS880 inverter, there is a large deviation between the collected main circuit current value and the value displayed on the inverter. How to solve this problem?

A: First, check whether the type of the inverter's current output signal (whether it is DC 4-20mA) is consistent with the configuration of the board's AI interface (to avoid current/voltage type mismatch); second, confirm that the current transformer (CT) ratio matches the software settings of the board (for example, if the CT ratio is 100A/5A, the board needs to be set to the corresponding range); finally, perform linear calibration on the AI interface through software (input standard DC 4mA and 20mA signals, and adjust the board's collected value to the corresponding standard value).

2、Q: When communicating with the main circuit equipment, the communication is frequently interrupted. How to troubleshoot?

A: The first step is to check the wiring of the communication line (whether the RS485 A/B lines are reversed and whether the Ethernet crystal head is crimped properly); the second step is to measure the electromagnetic interference intensity near the main circuit equipment (using an electromagnetic radiation detector, which should be ≤ 50V/m). If it exceeds the standard, the communication line should be replaced with a shielded twisted pair (with the shielding layer grounded) and routed separately from the main circuit power line; the third step is to reduce the communication rate through software (for example, reduce the Modbus baud rate from 115200bps to 9600bps) to enhance anti-interference ability.

3、Q: The "Isolation Fault" light on the board is always on and it cannot work normally. What should I do?

A: The lighting of this light indicates a fault in the main circuit signal isolation function. First, disconnect the main circuit power supply and check whether high voltage intrudes into the main circuit signal input terminal (such as whether AC 220V signal is incorrectly connected). If the terminal voltage is normal, it is necessary to check the board's isolation circuit (the isolation chip may be damaged). In this case, contact ABB after-sales service to replace the board. Do not disassemble and repair it by yourself (to avoid damaging the isolation performance).

4、Q: Can this product be interchanged with the old model 3BHE004573R0042? What issues should be noted

A: Their hardware interfaces (power supply, signal, and communication) are fully compatible and can be directly interchanged. However, two points should be noted: first, the analog acquisition accuracy of the new model 3BHE004573R0043 (±0.1%) is higher than that of the old model (±0.2%), so the signal acquisition value needs to be recalibrated after replacement; second, the new model supports Profinet Gigabit rate, while the old model only supports Fast Ethernet rate. If Gigabit communication is required, the communication module of the control system (such as the Ethernet module of AC 800M) needs to be upgraded to the Gigabit version.

Customers who purchased this product are also browsing the following products:

ABB CBI 20-P 3BDH000730R1 Binary Input Module

ABB GDB021BE HIEE300766R1 Control unit module

HONEYWELL LG1093AC01 Flame Detector

TRICONEX 3211S2 Digital Input module

3005319639

3005319639