Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. The 8310N2 power supply module is a key component of the Tricon V10 system. Through redundant design, comprehensive diagnostic functions, and rigorous environmental qualification, it ensures high reliability and availability in safety-related applications. This design complies with the General Design Criteria (GDC) in Appendix A of 10 CFR Part 50 and relevant IEEE standards, making it suitable for scenarios such as nuclear power plants where extremely high requirements are placed on power supply stability and safety.

Basic Information

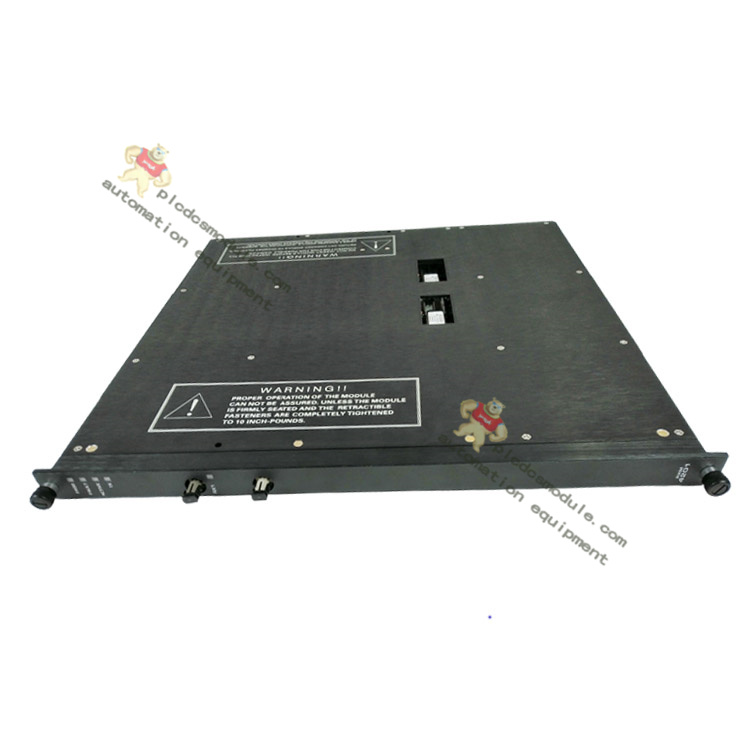

Model: 8310N2

Type: A high-density power supply module, part of the Tricon V10.5.1 system, designed to provide power support for Tricon PLC systems.

Input Voltage: 120 VAC/DC

Hardware Features

Power Specification: With a rated power of 175 watts, it sufficiently meets the power requirements of all expected configurations in safety-related applications.

Redundant Design:

- Two independent redundant power supply modules can be used per chassis, each capable of individually providing full power for the chassis. This ensures the system remains operational even if a single power module fails.

- It forms a series of power modules with different input voltages together with 8311N2 (24 VDC) and 8312N2 (230 VAC), and can be used in combination within the same chassis.

Backplane Power Architecture:

- The chassis backplane features a dual independent power rail design, where the two power rails supply power to three branches of each I/O module and the main processor module respectively.

- Each module obtains power independently through dual voltage regulators, ensuring that if one power rail or power module fails, the other can seamlessly take over the power supply.

Battery Backup: The main chassis backplane is equipped with dual redundant batteries, which can maintain data and programs in the main processor module for up to six months in the event of a complete power outage. An alarm will be triggered when the battery power is low.

Electrical Characteristics of the 8310N2 Power Module:

- Input Voltage: 120 VAC/DC (range: 85 - 140 VAC, 95 - 180 VDC), adaptable to various on-site power supply conditions.

- Input Frequency: 47 - 63 Hz (AC).

- Input Current: Maximum 2.75 A (typical steady-state 0.75 A).

- Inrush Current: Maximum 18 A (120 VAC/VDC, 1/2 AC cycle).

- Output Voltage: 6.5 VDC ±1%, providing stable DC voltage output for the system.

- Output Current: At least 27 A (at 60°C ambient temperature), capable of meeting the power requirements of multiple modules in Triconex controllers.

- Output Power: 175 W (at 60°C ambient temperature), sufficient for power demands of various configurations in safety-related applications.

- Output Overvoltage Protection: Typical value 115%, requiring a power-off restart to prevent damage to the system from excessive voltage.

- Output Overcurrent Limitation: Typical value 135%, usually with automatic restart, effectively protecting the system from overcurrent.

- Input Fuse: 5 A, time-delay type, enhancing circuit protection capability.

- Mechanical Specifications: Din-rail mountable design, facilitating easy installation and integration into the system.

- Safety Performance: Certified with Safety Integrity Level (SIL) 2, meeting certain safety standards and suitable for safety-critical environments.

Environmental Adaptability of the 8310N2 Power Module:

- Operating Temperature: 0°C to 60°C (32°F to 140°F); some data indicate a range of -40°C to 70°C, enabling adaptation to different operating environment temperatures.

- Relative Humidity: 5% to 95% (non-condensing), ensuring stable operation within a certain humidity range.

- Diagnostic Functions: Equipped with diagnostic indicator lights, including PASS (green, normal input power), FAULT (red, power module abnormality), ALARM (red, chassis alarm status), TEMP (yellow, over-temperature condition), and BATT LOW (yellow, low battery power), allowing users to promptly monitor the module's operating status.

- Redundant Design: Typically adopts a dual-redundancy design, where two identical power modules operate in parallel. If the main power module fails, the standby power module automatically and seamlessly takes over the power supply, improving the reliability of the system power supply and eliminating the impact of single-point failures.

Other Features: Equipped with comprehensive protection functions, such as an over-temperature warning sensor that issues an alert when the internal temperature of the module is too high. It also has a wide input voltage range, enabling adaptation to different on-site power supply conditions and enhancing the flexibility and applicability of the system.

Environmental Qualification and Testing

Testing Standards: Environmental qualification is conducted in accordance with specifications such as EPRI TR-107330, IEEE Std 323-2003, and RG 1.89.

Key Test Results:

- Temperature and Humidity: Passed tests in environments ranging from -40°F to 140°F (-40°C to 60°C) and 5% to 95% relative humidity (non-condensing). It continued to operate normally after 48 hours of operation under high-temperature and high-humidity conditions.

- Seismic Testing: Successfully passed Safe Shutdown Earthquake (SSE) and Operating Basis Earthquake (OBE) tests. It maintained normal functionality within the specified frequency range (with partial low-frequency bands not fully meeting standards due to equipment limitations).

- Electromagnetic Compatibility (EMI/RFI): Although slightly exceeding limits in certain frequency bands during conducted emission (CE), radiated emission (RE), conducted susceptibility (CS), and radiated susceptibility (RS) tests, it generally meets the requirements for safety-related applications.

- Electrical Fast Transient (EFT) and Surge Immunity: No functional interruptions or damage occurred during tests at ±2.0 kV on power terminals and ±1.0 kV on signal terminals.

- Electrostatic Discharge (ESD): The system operated normally during contact discharge tests at ±8 kV and air discharge tests at ±15 kV.

Application Limitations and Requirements

Environmental Limitations: Suitable for mild environments (e.g., main control rooms and auxiliary electrical equipment rooms) with a radiation tolerance dose of 1000 RAD (cobalt-60 gamma radiation).

Plant-specific Requirements:

- The expected on-site radiation exposure must be verified to be within the qualified range.

- Multimode fiber optic cables and connecting hardware must be provided by the user and individually verified to meet environmental conditions.

- The hold-up time of the power module (ability to maintain power supply after a power outage) must be at least 40 milliseconds to ensure uninterrupted system operation during brief power interruptions.

Differences from V9 Version

The corresponding power module in Tricon V9 is 8310N, and the 8310N2 is its upgraded version. While maintaining functional equivalence in hardware design, they are not interchangeable.

Upgrade enhancements primarily include improved reliability, optimized thermal design, and enhanced compatibility with other modules in the V10 system.

To ensure stable system operation, the TRICONEX 8310N2 power module is often used in conjunction with various products of the same brand:

- TRICONEX 8310: Similar to the 8310N2 but with differences in technical specifications or features. As a power module, it can complement the 8310N2 in certain application scenarios or serve as a backup option, jointly ensuring the reliability of the system power supply.

- TRICONEX 8311/8311N: High-density power modules in the Triconex system, which, like the 8310N2, supply power to the system. Their different output powers or characteristics enable them to work with the 8310N2 to meet the power requirements of different system modules, enhancing the overall flexibility and adaptability of the system's power supply.

- TRICONEX 8312: Featuring different voltage or current output specifications, it can work in collaboration with the 8310N2 to provide diversified power configuration solutions for the Triconex system, adapting to complex industrial power environments.

- TRICONEX Chassis (e.g., 8110/8111): Used to install the 8310N2 power module and other Triconex controller modules, providing physical support and electrical connections for each module. They form the basic framework for building the Triconex system.

- TRICONEX Main Processor Modules (e.g., 3008N): As the core processing units of the Triconex system, they rely on stable and reliable power supply from modules like the 8310N2 to operate normally. The two work closely together to realize the system's control and monitoring functions.

- TRICONEX I/O Modules (e.g., 3501TN2, 3502E, 3623T, 3704E, 3805E, etc.): These modules are used to connect on-site sensors and actuators, exchanging data with the main processor. They depend on the power supplied by the 8310N2 to collect and output on-site signals, serving as key components for the system to interact with external devices.

- TRICONEX Power Cables and Connectors: Used to connect the 8310N2 power module to the power supply and the Triconex system, ensuring stable and reliable power transmission and enabling the 8310N2 to effectively supply power to other modules.

Customers who purchased this product are also browsing the following products:

TRICONEX 3721 Analog Input Module

TRICONEX 3101S2 Triple Redundant Processor Module

GE IS200TBCIS2CCD Mark VI Turbine Control PCB Module

ABB GDC806C6003 3BHE044249R6003 PLC module

3005319639

3005319639