Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. SLIMPAK G468-0001 is a DIN rail-mounted AC input signal conditioning isolator belonging to the Ultra SlimPak series. Its core function is to convert AC current signals of 5mA-100mA or AC voltage signals of 50mV-250V into isolated DC outputs proportional to the average value of the full-wave rectified AC input signals. Meanwhile, it achieves 1800VDC electrical isolation between input, output and power supply. It is suitable for signal isolation, conversion and conditioning needs in industrial scenarios, and serves as a key signal processing component in energy management, equipment monitoring and data acquisition systems.

download:

SLIMPAK G468-0001 .pdf

SLIMPAK G468-0001 .pdf

Core Functional Advantages

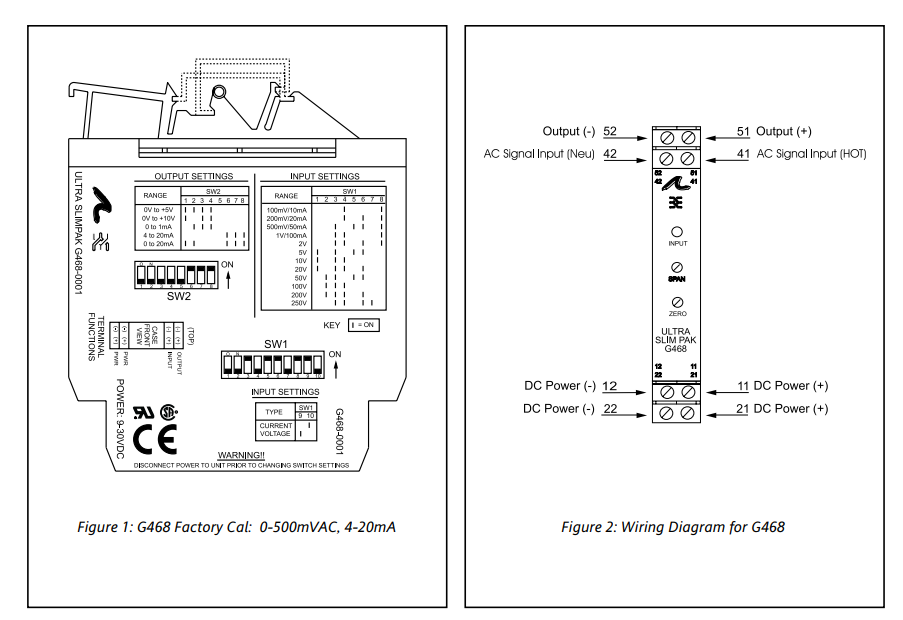

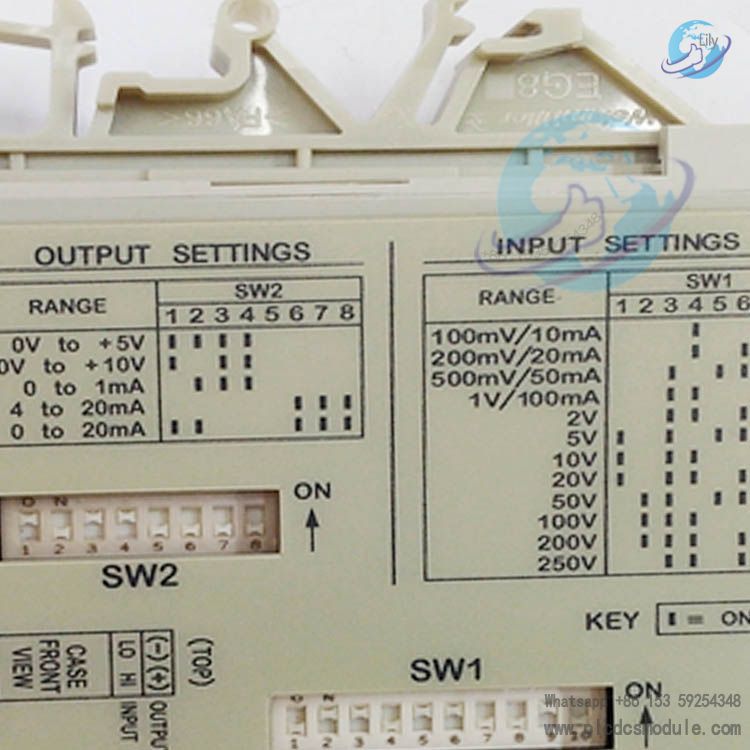

- Wide-Range Field Configurability: Supports switching between 15 input ranges (voltage: 100mV-250VAC, current: 10mA-100mA AC) and selection of 5 output types (0-5V, 0-10V, 0-1mA, 0-20mA, 4-20mA). Configuration can be flexibly done on-site via DIP switches (SW1, SW2), eliminating the need for hardware replacement to adapt to different sensors and control systems, thus reducing selection and inventory costs.

- Strong Isolation and Anti-Interference: The isolation voltage between input, output and power supply reaches 1800VDC, which can completely eliminate ground loop interference in industrial sites. The common mode rejection ratio (DC-60Hz) is up to 120dB, which can resist electromagnetic interference such as power grid fluctuations and equipment start-stop, ensuring the stability of signal transmission and avoiding control errors or equipment failures caused by interference.

- High-Precision Signal Conditioning: The typical value of signal conversion accuracy is ±0.1% of full scale, and the maximum value is ±0.5% of full scale. Linearity and hysteresis errors are included in the accuracy index. The temperature stability is ±0.025%/°C (typical value). Within the operating temperature range of 0-55°C, the signal drift is small, ensuring long-term measurement accuracy.

- Real-Time Status Diagnosis: Equipped with a green dual-function LED indicator. The LED stays on when powered on to indicate normal power supply. When the input signal exceeds 110% of the full scale, the LED flashes at a frequency of 8Hz; when the input signal is lower than -10% of the full scale, it flashes at 4Hz. This allows intuitive judgment of the device's power supply and signal status, facilitating quick fault troubleshooting.

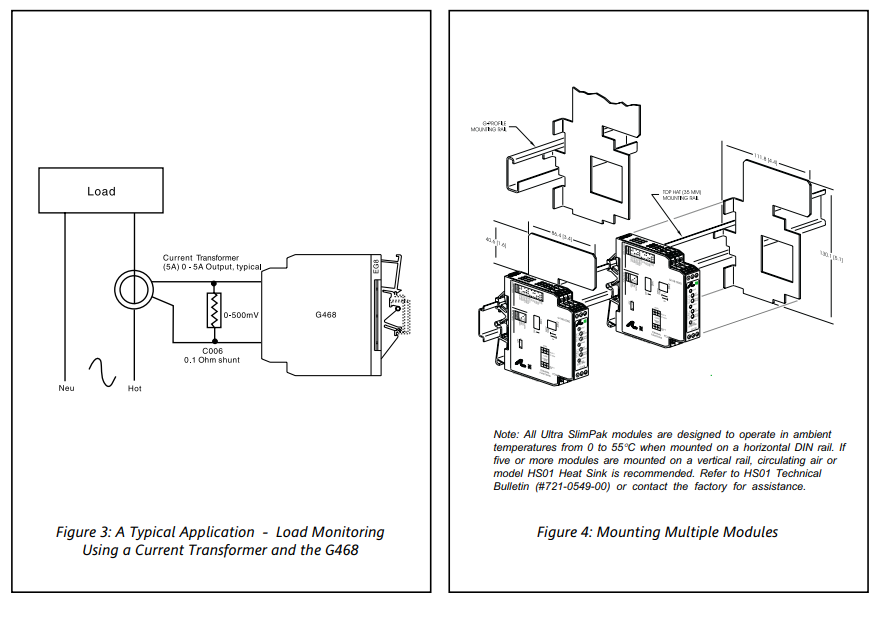

- High Compatibility and Integration: It has a wide DC power input range (9-30VDC), compatible with 12VDC, 24VDC and other commonly used industrial power supplies. The output can directly drive control devices such as digital meters, PLCs, DCS or alarm devices, without the need for additional signal conversion modules, simplifying system wiring and integration processes.

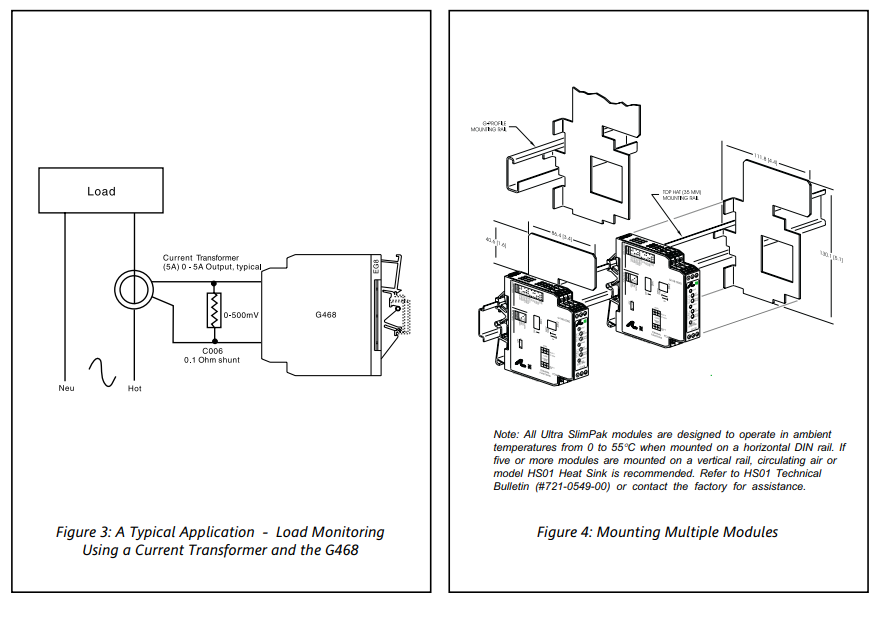

- Compact and High-Density Installation: Adopts Ultra SlimPak ultra-thin housing design, compatible with standard TS32 (MD02) and TS35 (MD03) DIN rails. A single module occupies small space and supports dense installation of multiple modules (note that ventilation or HS01 heat sinks are required when installing 5 or more modules vertically), improving the space utilization of the control cabinet.

- Enhanced Reliability Design: Uses ASIC (Application-Specific Integrated Circuit) technology to reduce the number of discrete components and fault points. It has input overvoltage protection up to 300VAC (for voltage input) and overcurrent protection up to 200mAAC (for current input). The power reverse connection and overload protection mechanisms are complete, with a long mean time between failures, making it suitable for harsh industrial environments.

Key Technical Specifications

1. Input Parameters

| Input Type | Range | Impedance Characteristics | Over-Protection Specification | Frequency Range |

|---|

| AC Voltage | 100mV-250VAC | >100K Ohms | 300VAC (Overvoltage) | DC/40-400Hz AC |

| AC Current | 10mA-100mA AC | 20 Ohms (Typical) | 200mAAC (Overcurrent) | DC/40-400Hz AC |

| Common-Mode Isolation | - | - | 1800VDC (Maximum) | - |

2. Output Parameters

| Output Type | Range | Source Impedance / Load Requirement | Maximum Driving Capacity |

|---|

| DC Voltage | 0-5V, 0-10V | <10 Ohms (Source Impedance) | 10mA (Maximum) |

| DC Current | 0-1mA | >100K Ohms (Source Impedance) | 7.5V (Maximum Compliance Voltage) |

| DC Current | 0-20mA, 4-20mA | >100K Ohms (Source Impedance) | 12V (Maximum Compliance Voltage) |

3. Performance & Environmental Parameters

- Accuracy: ±0.1% of full scale (Typical), ±0.5% of full scale (Maximum)

- Response Time: 10%-90% step response, 250ms (Typical)

- Operating Temperature: 0-55°C (Horizontal DIN Rail Mounting)

- Storage Temperature: -25-70°C

- Operating Humidity: 15%-95% (at 45°C, no condensation); 90% (24 hours, at 65°C, immersion test)

- Power Consumption: 1.5W (Typical), 2.5W (Maximum)

- Terminal Blocks: Screw terminals, compatible with 12-22 AWG wires

- Weight: 0.48 lbs (approximately 0.22kg)

Typical Application Scenarios

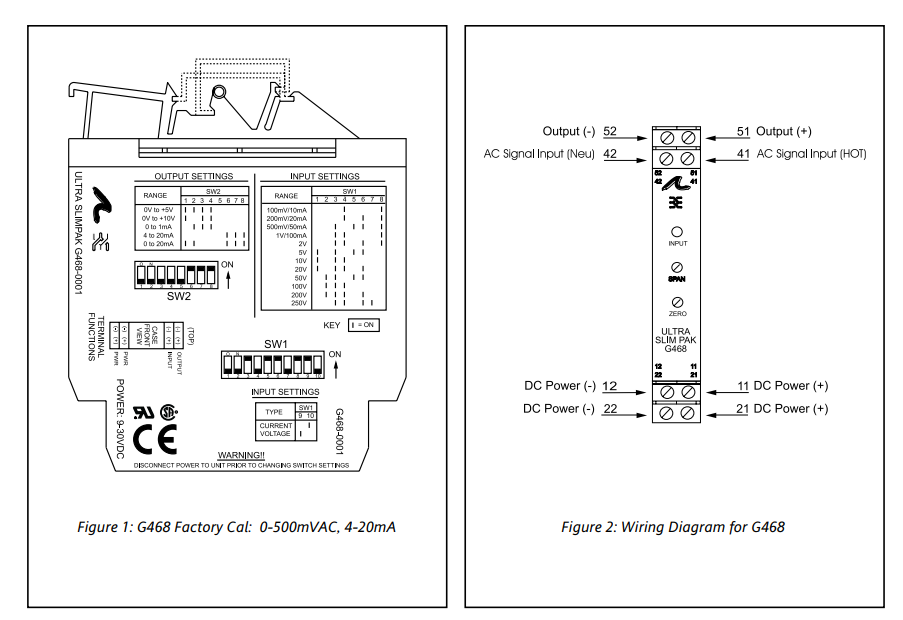

- Energy Management Systems: Connect to current transformers (requires matching C006 shunt resistor, 0.1Ω/5W, for AC current measurement above 100mA) or voltage sensors. Convert AC current and voltage signals of power grids/equipment into 4-20mA standard signals, which are transmitted to the energy monitoring platform to realize energy consumption metering and load analysis.

- Motor Monitoring and Protection: Monitor motor operating current (via current transformer + G468), and connect the output signal to a PLC. This enables motor load monitoring and locked-rotor detection (sudden current increase); when the current exceeds the limit, the PLC triggers an alarm or shutdown protection to prevent the motor from burning out due to overload.

- Industrial Equipment Load Monitoring: For equipment such as pumps, fans, and compressors, use G468 to collect the equipment's operating current signals. Convert the signals into 0-10V signals to drive digital meters for display, or connect them to a DCS system. This allows real-time monitoring of equipment load changes and prediction of maintenance needs (refer to "Figure 3: Typical Application of Load Monitoring").

- Data Acquisition and Isolation: In multi-equipment centralized monitoring systems, use G468 to achieve isolation and unified conversion of signals from different equipment (e.g., convert scattered 20mV and 50VAC signals into 4-20mA). This avoids ground loop interference between equipment and ensures the accuracy and stability of the data acquisition system.

Alarm and Control Linkage: Convert AC signals output by sensors (such as AC signals from pressure switches and flow switches) into DC signals, and connect them to an alarm controller. When the signal exceeds the limit, it triggers an audible and visual alarm, or links the actions of actuators such as valves and pumps to realize safe control of industrial processes.

Customers who purchased this product are also browsing the following products:

ABB UAD154A 3BHE026866R0101 PCB board

Alstom ESA-700 EPSD-0375-1108 Flame Signal Analyzer

ABB GVC704AE01 3BHB003023P201 IGCT Module

Bently Nevada 9200/06-01-10-00 Vibration sensor

3005319639

3005319639