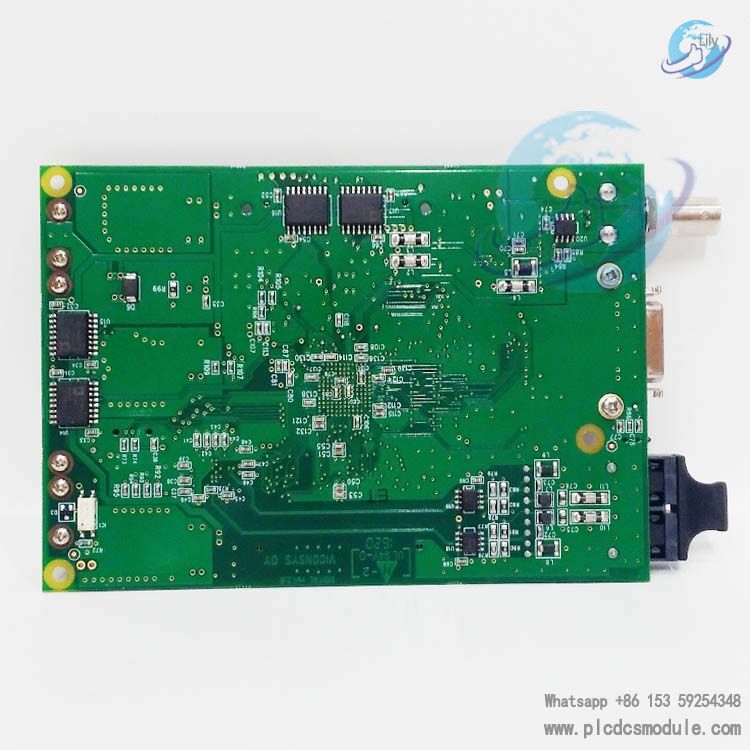

The VALMET PQV80020041 PCB (Printed Circuit Board) is a mission-critical industrial component engineered exclusively for Valmet’s process automation ecosystems, including Valmet DNA and Valmet IQ systems. As a genuine Valmet part, it serves as the "nerve center" for power distribution, signal transmission, and device communication in heavy industries like pulp & paper, energy, chemicals, and mining. Designed to withstand harsh industrial conditions—extreme temperatures, vibration, and electromagnetic interference (EMI)—this PCB ensures seamless integration, minimal downtime, and long-term reliability for Valmet-controlled processes. This guide covers its core features, technical specs, applications, sourcing, and maintenance, optimized for engineers, maintenance teams, and procurement professionals seeking trusted information for system upkeep and integration.

Severe Environment Resistance: Adaptable to Complex Working Conditions in Heavy Industry

Scenarios in heavy industry (pulp and paper, energy, chemical engineering, mining) are generally plagued by issues such as extreme temperature fluctuations, continuous vibration, and strong electromagnetic interference (EMI). Through special design and material selection, this PCB achieves strong resistance to harsh environments:

Wide Temperature Operating Range

It adopts industrial-grade high-temperature/low-temperature resistant components, with an operating temperature range typically covering -40℃ to +85℃ (please refer to the official technical manual for specific values). It can adapt to scenarios like high-temperature drying workshops in paper mills, outdoor low-temperature control cabinets in mines, and sudden temperature changes in chemical workshops, preventing circuit failure caused by abnormal temperatures.

Vibration and Shock Resistance

The PCB substrate is made of high-rigidity epoxy glass cloth substrate (e.g., FR-4 reinforced material). Components adopt a "solder joint anti-detachment reinforcement process" (such as pin glue fixing and secondary reinforcement after wave soldering). Its vibration resistance level complies with the IEC 60068-2-6 standard (sinusoidal vibration: 10~500Hz, acceleration 50m/s²), and shock resistance meets the IEC 60068-2-27 standard (half-sine shock: peak acceleration 100m/s², duration 11ms). It can cope with working conditions like vibration from mining equipment operation and high-frequency vibration from chemical pump sets.

Strong Electromagnetic Interference (EMI) Protection

It integrates multiple EMI protection designs, including:

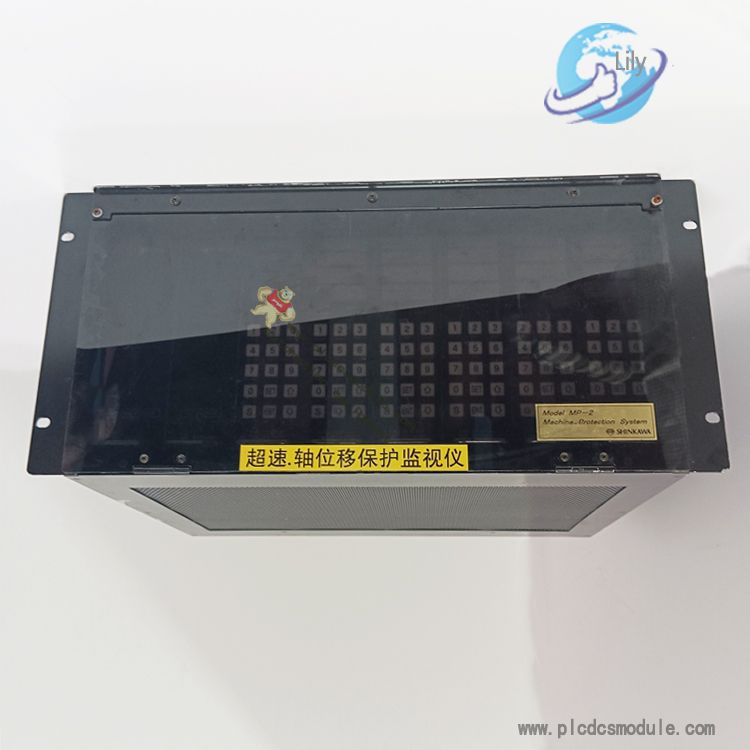

Customers who purchased this product are also browsing the following products:

ABB PP D113 B03-25-110110 3BHE023584R2541 AC 800PEC CONTROLLER BOARD

ABB PM863K01 3BSE088381R1 AC 800M CONTROLLERS

HONEYWELL FC-SDIL-1608 digital input module

TRICONEX AIH 3723X TMR Analog input module

3005319639

3005319639