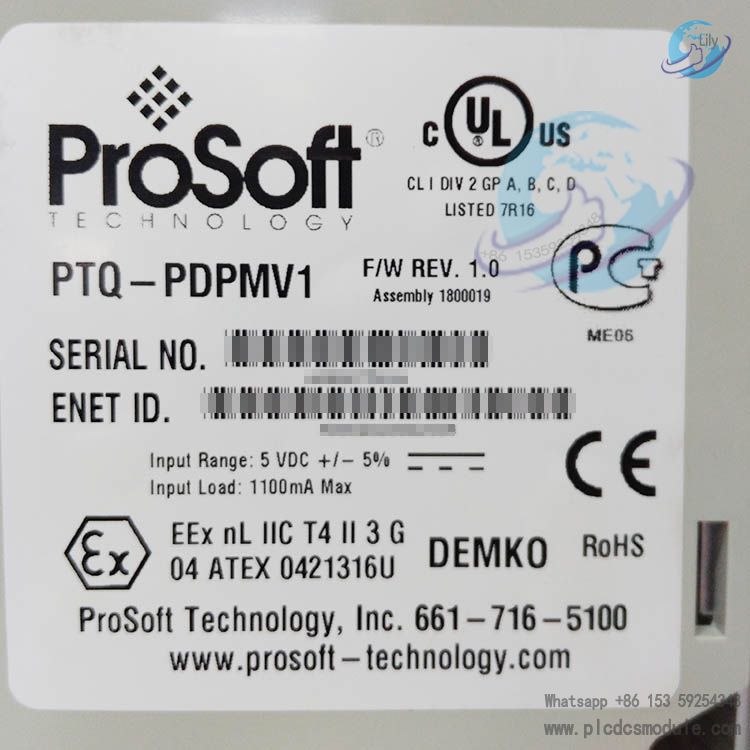

The PROSOFT PTQ-PDPMV1 is a PROFIBUS DP V1 master station network interface module specifically designed for Quantum processors. Developed in compliance with the IEC 61158 master station standard, it integrates proprietary backplane technology to achieve efficient data interaction with the processor. It supports communication with DPV0/V1 protocol slave devices and features acyclic parameter transmission, network diagnosis, and hot standby redundancy functions. As a core communication component connecting Quantum systems and PROFIBUS networks in industrial automation scenarios, it has obtained certifications from Schneider Electric CAPP program and the PROFIBUS Trade Organization (PTO).

File Download:

I. Core Functions and Advantages

Comprehensive protocol compatibility and communication capabilities: The module fully complies with the PROFIBUS DPV1 master station specifications, enabling acyclic parameter data transmission via Class 1 or Class 2 DPV1 services, and easily communicates with slave devices supporting PROFIBUS DPV0/V1 protocols. It also supports PROFIBUS PA slave station access to the network through DP/PA couplers or links. A single module can connect up to 125 slave devices with the cooperation of repeaters, and supports all standardized baud rates (up to 12 Mbits/s) and automatic baud rate detection, adapting to communication needs of different industrial sites.

Flexible configuration and management methods: The module is equipped with ProSoft Configuration Builder (PCB) software, providing a PC-based configuration solution. It not only supports a drag-and-drop Busview configuration interface for easy design, configuration, and monitoring of PROFIBUS networks but also allows importing historically valid configuration files into new projects to reduce repetitive operations. Additionally, it has built-in FDT/DTM communication software (product number PSW-CDTM-PDPM), which can interface with compliant FDT software containers, device DTMs, and PROFIBUS slave devices. It also supports remote configuration of the module and PROFIBUS network via Ethernet, reducing on-site maintenance costs.

High reliability and expandability: The module is built based on Siemens ASIC ASPC2 Step E chip and Infineon C165 microprocessor. Its firmware supports flash memory upgrades, enabling function updates without replacing hardware. In terms of installation layout, the single-slot design is compatible with the Quantum backplane, allowing up to 6 such modules per rack (up to 4 in hot standby scenarios). It is recognized as an "Options module" and can access PLC memory for data transmission, adapting to the expansion needs of industrial control systems of different scales.

Stable hot standby redundancy and fault protection: The module supports the Unity HEC hot standby function specification, is compatible with SE 140 671 CPU, and can automatically detect the hot standby system without additional parameter settings. The nominal master-slave switchover time is only 100 ms, with a maximum of no more than 300 ms, effectively ensuring continuous system operation. It also features cable break detection, which can provide information on the number of slave stations in segmented networks. The secondary master station can generate PROFIBUS health messages through FDL ping services, and cooperate with diagnostics and status words to feed back the health status of master and slave devices, enabling quick fault location.

Rich diagnostic and monitoring capabilities: The module supports extended diagnostic data, alarm indication and confirmation processing, as well as multicast and broadcast messages (both compliant with DPV1 standards), enabling real-time feedback of network operation status. It has a built-in CRC check function to verify the consistency between slave configuration and the processor, avoiding communication errors. In addition, the module is equipped with multiple sets of LED indicators, including indicators for module status, backplane transmission status, serial port activity, PROFIBUS master operation/network communication/token holding/database configuration, etc., facilitating on-site personnel to intuitively judge the equipment operation status.

II. Key Technical Parameters

Basic specifications: The module features a single-slot design, compatible with the Quantum backplane, and must be installed in the same rack (local rack) as the Quantum processor. Configuration data is stored in the module’s non-volatile memory and will not be lost after power failure. It supports all common Quantum programming software, including Concept (version 2.6 and above), Unity Pro (version 2.2 and above), and ProWORX (version 2.20 and above). Note that the hot standby function is only available in the Unity Pro environment. It also supports 3x and 4x data types of the Quantum system and provides sample ladder diagram files for easy onboarding.

Communication interface parameters: The PROFIBUS master interface uses a 9-pin D-type female connector (RS-485) with optocoupler isolation protection. Configuration ports include a DB-9 male RS-232 port (without hardware handshaking) and an RJ45 Ethernet port (with link and activity LED indicators), meeting configuration and debugging needs in different scenarios. The backplane data transmission speed is high, enabling efficient data interaction between the processor and the module. Data transmission is asynchronous with I/O data transmission on the PROFIBUS network, ensuring no mutual interference.

Environmental and physical characteristics: Operating temperature range is 0°C to 60°C (32°F to 140°F), storage temperature range is -40°C to 85°C (-40°F to 185°F), and relative humidity tolerance is 5% to 95% (non-condensing), adapting to complex temperature and humidity environments in industrial sites. Vibration resistance meets 4-100 Hz sinusoidal vibration (on 3 orthogonal axes), and shock resistance reaches 30 g (11 ms, on 3 orthogonal axes). Dimensions are approximately 250×103.85×40.34 mm (height × width × depth), with a weight suitable for installation in industrial control cabinets.

Power supply parameters: The module requires no additional external power supply and draws power exclusively from the Quantum backplane. The maximum backplane current load is 1100 mA (at 5 Vdc ±5%), with a power consumption design compliant with low-energy requirements for industrial equipment.

III. Installation and Operation Requirements

Installation specifications: The module must be installed in the same rack as the Quantum processor to ensure stable backplane connection. During wiring, interface terminal definition specifications must be followed—especially the phase and polarity of the PROFIBUS master interface—to avoid communication issues caused by incorrect wiring. The installation environment should be free from condensation, strong vibrations, and strong electromagnetic interference sources. Meanwhile, adequate ventilation in the control cabinet must be ensured to maintain the module’s operating temperature within the specified range, thus guaranteeing stable equipment operation.

Operation and maintenance: Daily operations can be performed via local HMI, Web HMI, or PCM600 software. The module supports four levels of user permissions (VIEWER, OPERATOR, ENGINEER, ADMINISTRATOR), allowing permission allocation based on personnel responsibilities. During maintenance, the module’s self-monitoring function feeds back device status via IRF contacts. Fault recordings and event logs (supporting 2048 system events and 1024 process events) use FIFO storage, facilitating engineers in tracing fault causes. Additionally, the module supports hot-swap operations, enabling replacement during system runtime to reduce downtime.

3005319639

3005319639