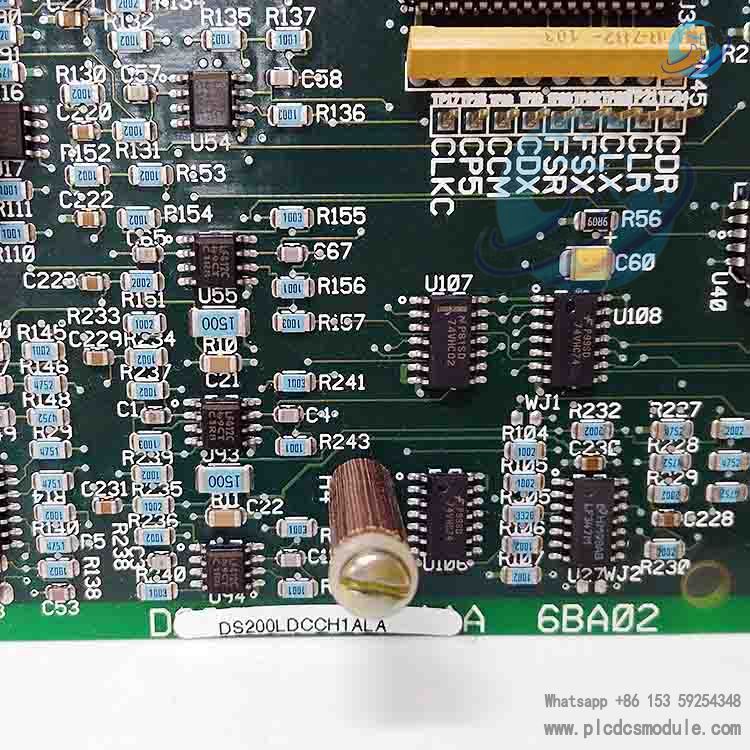

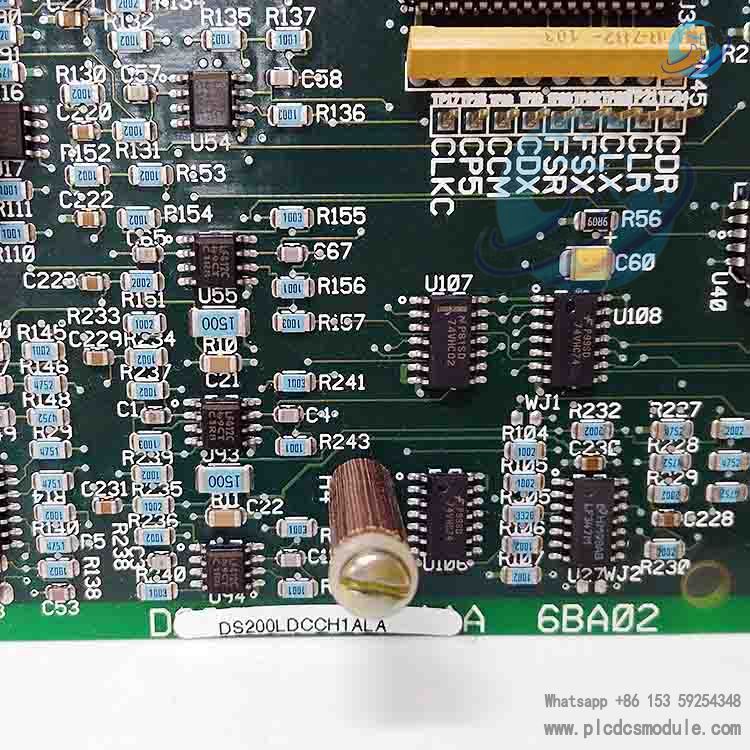

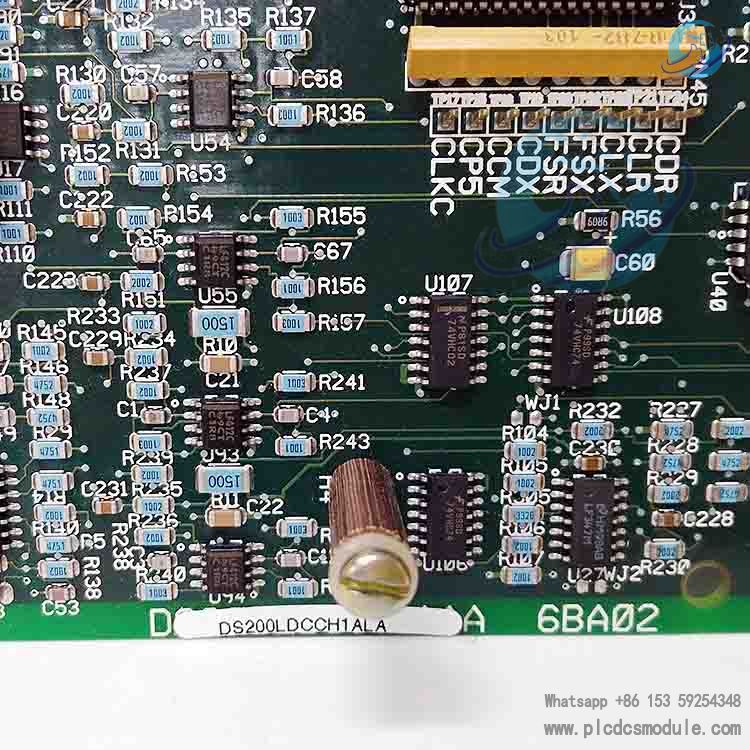

Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. DS200LDCCH1ALA is a core interface module developed by General Electric (GE) specifically for the Mark V turbine control system and industrial automation scenarios. It integrates two core functions: drive control and local area network (LAN) communication, and serves as a key component of the Mark V series. As a "signal bridge" between the system and on-site equipment, this module enables seamless connection of control command transmission, I/O signal processing, and multi-protocol data interaction. It is widely adapted to harsh working conditions in industries such as power, oil and gas, metallurgy, and chemical engineering. With high reliability, flexible compatibility, and stable performance, it has become a preferred component for core scenarios including large motor drives, turbine control, and production line automation.

With a multi-functional integrated design, the GE DS200LDCCH1ALA meets the needs of complex industrial control, with its core functions focusing on signal processing and system collaboration:

- Drive Control Function: It can directly control large motors, pumps, actuators and other equipment. It supports three mainstream modes: V/Hz control, sensorless vector control, and flux vector control. These modes adapt to the speed regulation, start-up and shutdown needs of different load types, enabling precise process control and position control.

- Signal Processing Capability: It efficiently receives and converts PLC control signals and on-site sensor signals, completes bidirectional conversion between digital quantities and analog quantities, and supports parallel processing of multi-channel I/O signals, ensuring the real-time performance and accuracy of data transmission.

- Communication and Interconnection Function: As a local area network (LAN) communication board, it supports data interaction across devices and systems, and seamlessly connects the Mark V control system with the distributed I/O architecture, providing unified communication support for the overall automation system.

- Logical Operation and Command Execution: Equipped with a high-efficiency processing unit, it can independently execute preset control logic, quickly respond to control commands, and implement key operations such as equipment status monitoring, fault early warning and emergency shutdown, improving system safety redundancy.

Core Advantages of GE DS200LDCCH1ALA

- High Reliability: Adopts industrial-grade high-quality components and undergoes strict quality testing, with a Class A reliability rating. It has strong fault tolerance, enabling long-term stable operation in harsh environments such as high/low temperatures, corrosion, and vibration, thus reducing the risk of fault-induced downtime.

- Flexible Compatibility: The modular design supports seamless combination with other modules in the Mark V series, while also being compatible with third-party PLCs and automation equipment. Its multi-protocol support capability allows it to be easily integrated into existing control systems without large-scale modifications.

- Ease of Use and Maintenance: Equipped with a user-friendly operating interface and graphical programming support, it features a simple installation process. Standardized interfaces facilitate quick replacement and upgrades, significantly reducing operation and maintenance costs as well as technical barriers.

- High Efficiency and Energy Saving: The low power consumption design balances operational efficiency and energy conservation. It has a fast dynamic response speed, with an acceleration time of less than 10 seconds. While improving control accuracy, it reduces energy consumption, achieving dual optimization of economy and performance.

Application Fields

- Energy Industry: Turbine control in power plants, equipment drive in substations, monitoring of oil and gas extraction and transportation pipelines, and automated control of facilities such as oil wells and storage tanks.

- Manufacturing Industry: Motor drive and process control for machinery manufacturing production lines, automobile manufacturing assembly lines, and food processing equipment; adapted for the collaborative operation of equipment such as robots, conveyors, and machine tools.

- Heavy Industry: Process control for iron and steel manufacturing in the metallurgical industry, monitoring of reactors and conveying systems in the chemical industry, and automated regulation of sewage treatment equipment and waste treatment systems in the environmental protection field.

- Infrastructure: Power equipment control in transportation fields such as railways and aviation; regulation of lighting and air conditioning systems in building automation; and signal processing and control of automated testing equipment.

Customers who purchased this product are also browsing the following products:

ABB PM863K01 3BSE088381R1 AC 800M CONTROLLERS

METSO PDP601 DPU Distributed Processing Unit

Schneider 140CPU67160 CPU Module

Honeywell LCNP4E 51405098-100 Interface Card

3005319639

3005319639