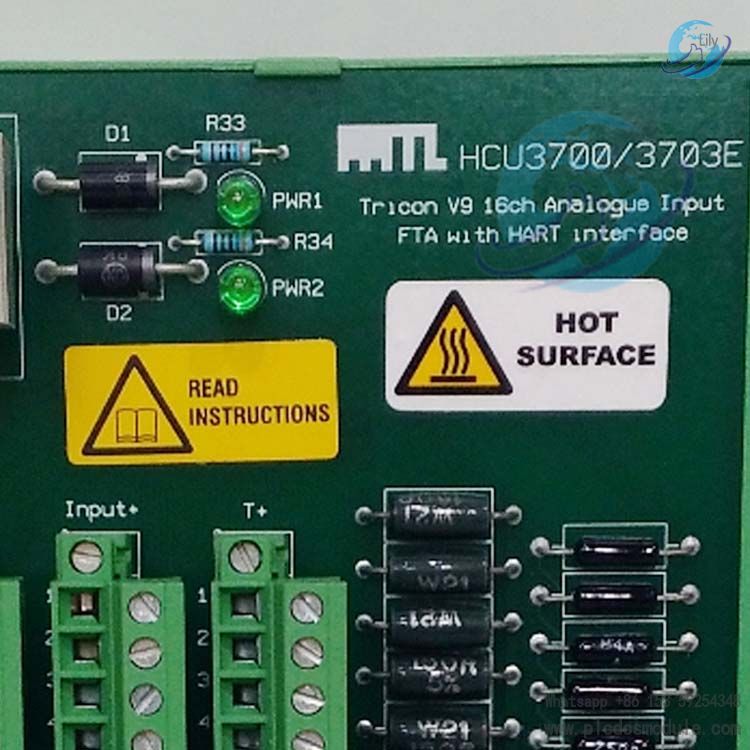

This module enables accurate analog signal acquisition and supports HART smart device communication in safety-critical scenarios such as petrochemicals, power generation, and metallurgy. It balances signal acquisition precision, system fault tolerance, and device diagnostic capabilities, ensuring the stable and reliable operation of process control and safety interlock systems.

Core Parameters

Channel Configuration

Signal Types & Ranges

- Voltage signals: 0–5V, 0–10V, ±5V, ±10V

- Current signals: 0–20mA, 4–20mA (compatible with 5V/10V voltage acquisition via 250Ω/500Ω shunt resistors)

- It supports HART 5/7 protocols and is compatible with field devices such as HART smart transmitters.

Accuracy & Resolution

Update & Response Time

The single-channel input update rate is approximately 50ms, with an overall response time of <250ms, meeting the requirements for real-time monitoring.

Electrical Isolation & Anti-interference

- Common-mode rejection ratio: ≥-100dB (DC), ≥-90dB (60Hz)

- Common-mode voltage range: Peak value +200V

- Inter-channel isolation: Typical value 20kΩ, supporting continuous overvoltage protection (150VDC/115VAC)

Environmental Conditions & Power Consumption

- Operating temperature: -40℃~70℃; Storage temperature: -40℃~85℃

- Powered by 24VDC with a power consumption of approximately 20W, suitable for harsh industrial operating conditions.

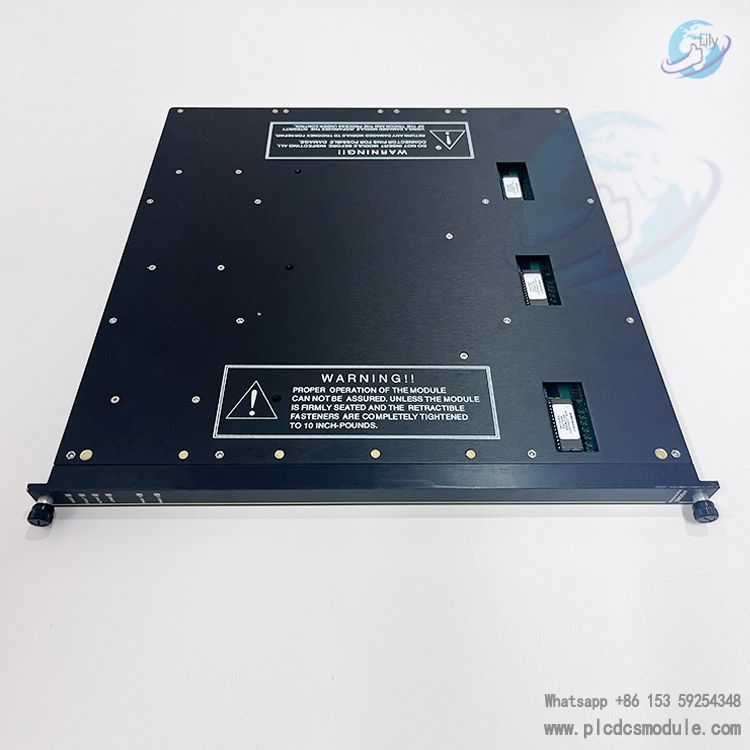

Physical Specifications

It is compatible with the Tricon V9 system backplane and supports hot swapping, allowing online module replacement to minimize downtime.

Core Functions

HART Communication CapabilityIt supports the HART protocol, enabling digital communication to be superimposed on 4–20mA analog signals. This allows remote configuration and diagnostics of field devices without interrupting the analog signal transmission.

TMR Architecture DesignThree independent channels perform parallel signal acquisition and voting. The system remains operational even if a single channel fails. Combined with channel-level diagnostics (e.g., open circuit, overcurrent, overrange), it reports and locates faults in real time, ensuring high system availability.Hot Swap & Online MaintenanceSupporting the hot-spare function, faulty modules can be replaced online without system shutdown, reducing the risk of production interruption and adapting to industrial scenarios requiring continuous operation.Safety & ComplianceCompliant with safety standards such as IEC 61508 and meeting SIL 3 safety integrity requirements, it is suitable for safety-critical loops including emergency shutdown (ESD) and fire & gas detection (F&G). It has passed rigorous electromagnetic compatibility (EMC) and vibration tests, adapting to the complex electromagnetic environment of industrial sites.System CompatibilityIt is compatible with Tricon system backplanes and External Terminal Panels (ETP), supports integration with DCS/SIS systems via protocols such as Modbus, and allows unified configuration, monitoring and diagnostics through system software, simplifying engineering implementation and operation & maintenance.

Application Scenarios

- Petrochemical IndustryIt is used for the acquisition of critical parameters such as pressure, temperature and liquid level in oil refining units and chemical reactors. Cooperating with HART devices, it enables catalyst injection, closed-loop control of reaction pressure and safety interlock.

- Power & Energy IndustryIt monitors signals including boiler drum water level, steam pressure and steam turbine speed in power plants, ensuring stable unit operation and emergency shutdown in case of faults.

- Metallurgical & Pharmaceutical IndustriesIt realizes high-precision acquisition of parameters like high-temperature furnace temperature, material flow rate and pharmaceutical ingredient ratio, meeting the requirements of process control and GMP compliance.

- Oil & Gas Storage and TransportationIt collects signals such as pipeline pressure, flow rate and leak detection. Through HART diagnostics, it can timely detect issues like transmitter drift and pipeline blockage, ensuring the safety of transportation.

Key Installation & Integration Requirements

- It must be properly connected to the Tricon system backplane to ensure the normal operation of redundant communication links. Address planning shall be carried out for the 16 channels corresponding to on-site HART devices to avoid address conflicts.

- Power supply and wiring must comply with the 24VDC polarity requirements. Analog signal wires and HART communication wires shall be routed separately with shielding to reduce electromagnetic interference.

- Configure channel signal types, measuring ranges, alarm thresholds and HART parameters through the Tricon system software, and enable channel diagnostic and redundant voting functions.

- Regularly verify device parameters via HART communication, and conduct preventive maintenance in combination with module diagnostic logs to extend device service life and ensure system safety.

Customers who purchased this product are also browsing the following products:

TRICONEX 4351A TCM Communication Module

TRICONEX 3721 Analog Input Module

triconex 3624 TMR Digital Output Module

Triconex 3008 Main Processors MP3008

3005319639

3005319639