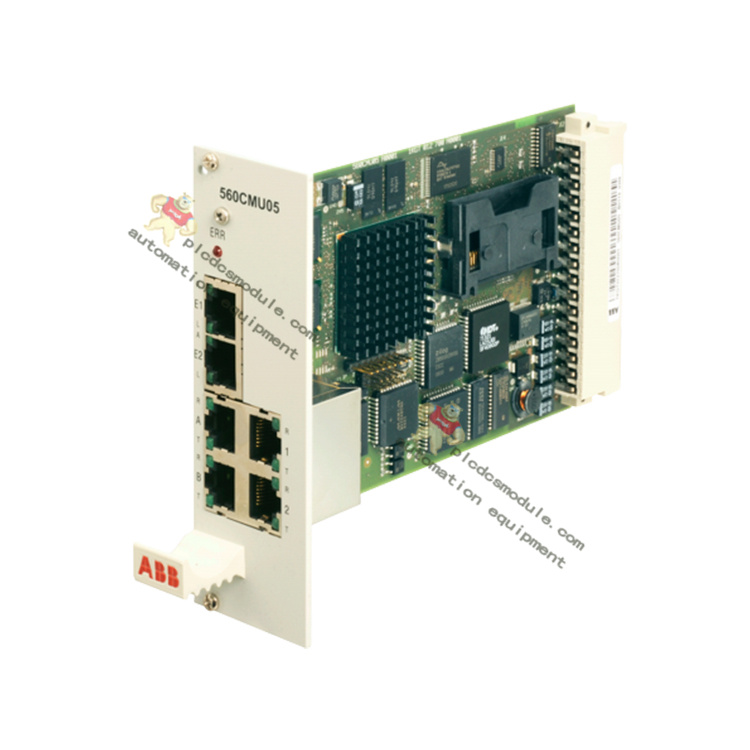

Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. The ABB DSQC639 3HAC025097-00116 Main Computer serves as the core main computer unit of the ABB IRC5 robot control system. It undertakes core tasks including robot motion control, program execution, system resource scheduling and external communication. Integrated with a high-performance processor, memory, storage and multi-protocol communication interfaces, it provides the robot with precise, stable and efficient control capabilities. Compatible with the full range of IRB robots, it is widely used in industrial automation scenarios such as automotive manufacturing, electronic processing and metalworking, and acts as the "brain" component that ensures the reliable operation of the robot system.

Technical Parameters

The model is DSQC639 (part number: 3HAC025097-00116). It is compatible with the ABB IRC5 robot controller (and supports systems such as M2004). Its core processor is the Intel Atom N270 1.6GHz (dual-core). The memory capacity is 2GB DDR2 (supporting expansion up to 4GB). The storage space is 16GB SSD (supporting expansion with industrial-grade CF cards). It is equipped with communication interfaces including 2×EtherNet/IP, 1×PROFINET, 1×DeviceNet and serial ports. It supports digital input/output channels for I/O expansion, facilitating external signal interaction. It features SIL3-level safety PLC functionality and is compatible with the SafeMove safety system. It meets industrial-grade standards, with anti-electromagnetic interference and wide-temperature operation capabilities, making it suitable for harsh factory environments.

Core Functions

Motion Control CoreEquipped with a high-performance processor, it can perform real-time calculations of complex kinematics algorithms, and precisely control the motion trajectory, speed and acceleration of robot axes 1 to 6 as well as external axes. It supports multi-axis synchronization and high-precision path planning, ensuring the operational accuracy and motion smoothness of the robot, and shortening the production cycle.

Program and Data ManagementBuilt-in large-capacity memory and storage units are used to store robot programs, system parameters, motion trajectory data and process recipes. It supports fast data reading and writing to ensure system response speed, and is equipped with data backup and recovery functions to prevent data loss and ensure production continuity.

Multi-protocol Communication InteractionWith a rich set of communication interfaces, it supports mainstream industrial protocols such as EtherNet/IP, PROFINET and DeviceNet. It can seamlessly connect with external devices including PLCs, HMIs and sensors, realizing high-speed data interaction and multi-device collaborative operation, and adapting to the requirements of flexible production.

System Monitoring and DiagnosisIt monitors the robot's operating status in real time, including axis load, temperature and communication status. The built-in fault diagnosis function can quickly locate system abnormalities and generate alarm information. It supports remote maintenance and diagnosis, reducing downtime and maintenance costs.

Safety Collaborative ControlWorking in conjunction with the SafeMove safety system, it supports functions such as emergency stop, safety gate monitoring and axis position safety limitation. It complies with safety standards including SIL3, and ensures the safety of personnel and equipment through independent safety channels and redundant verification mechanisms.

Application Scenarios

Automotive Manufacturing: In robotic operations such as welding, painting and assembly, it precisely controls the trajectory and posture of robotic arms to ensure welding accuracy and coating uniformity. Meanwhile, through multi-device communication and collaboration, it meets the rapid model change requirements of flexible production lines.

Electronic Processing: In high-precision assembly scenarios, it controls the robot’s end effectors to pick, place and assemble micro-components. Relying on high-speed data processing capabilities, it satisfies the high-cycle and high-precision production requirements of the electronics industry.

Metal Processing: In processes such as laser cutting and bending, it adjusts robot motion parameters in real time to adapt to different metal materials and processing techniques, ensuring processing quality and improving production efficiency.

General Industrial Automation: It is suitable for various robot workstations equipped with IRC5 controllers, especially for large-scale automated production lines that require multi-device collaboration, remote monitoring and diagnosis, optimizing production management processes.

Advantages & Highlights

High Performance and Reliability: Featuring an industrial-grade hardware design with redundancy and fault-tolerant mechanisms, it can operate stably 24/7 to meet continuous production needs and reduce the risk of system failures.

Flexible Adaptation and Expansion: It is compatible with the full range of IRB robots, supports external axis expansion and multi-robot control. Communication interfaces can be flexibly configured to adapt to the automation architectures of different factories.

Convenient Maintenance and Upgrade: It supports remote diagnosis, program upload/download and system upgrade. Parameters configuration and function expansion can be quickly completed via ABB RobotWare software, reducing maintenance difficulty and costs.

Safety and Compliance: It complies with multiple international safety standards and is deeply integrated with the SafeMove safety system to provide comprehensive safety protection, helping enterprises meet industrial safety specification requirements.

3005319639

3005319639