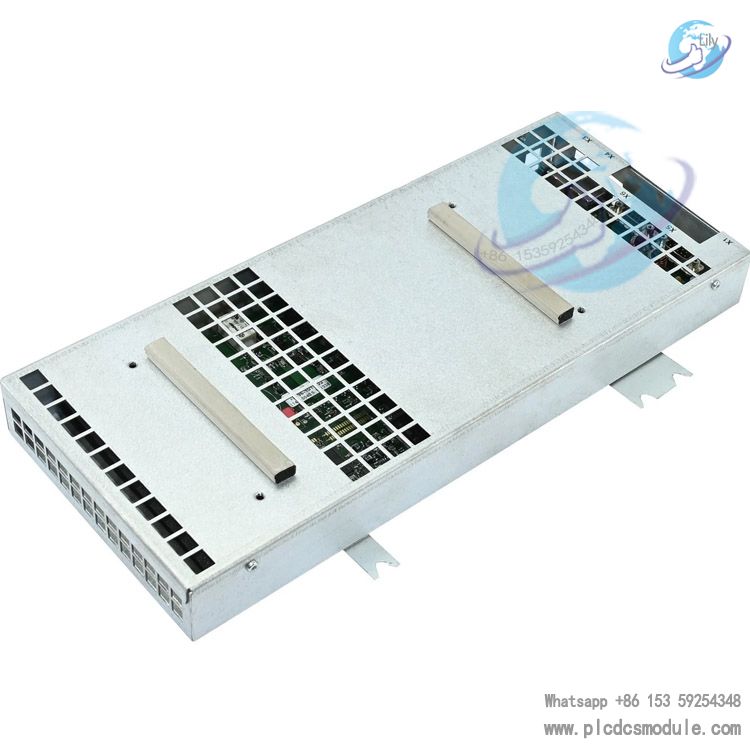

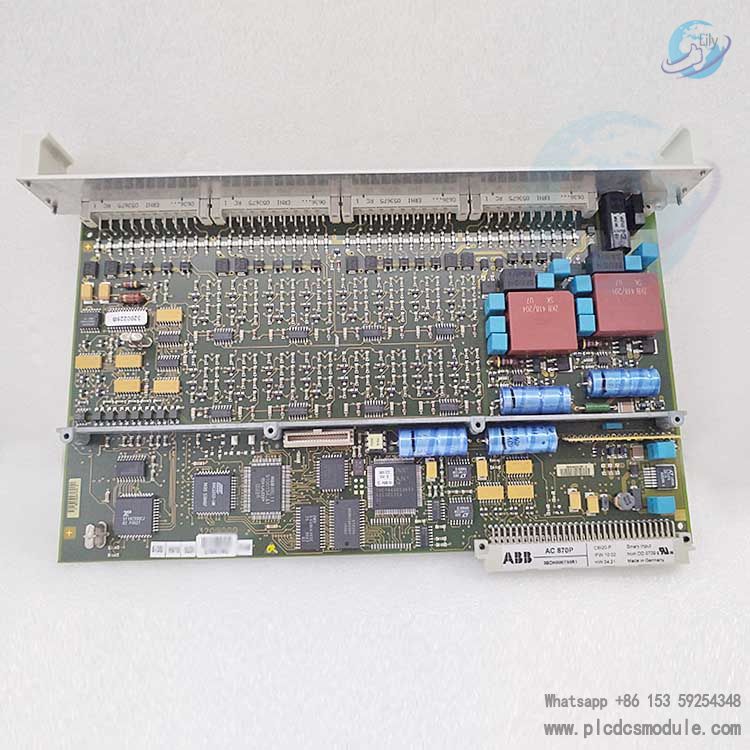

Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. The ABB 3HAC026271-001 ELAN EPS unit is an Electronic Position Switch (EPS) unit matched for ABB robots. As a key component of the ABB SafeMove safety system, it is specifically designed for the IRC5 controller. It can replace traditional mechanical limit switches and monitor the positions of robot axes 1 to 6 via purely electronic and software-based methods. It provides flexible and high-level safety protection, and is suitable for industrial automation scenarios with strict requirements for robot motion safety.

Core Functions

Full-axis Position Monitoring: It covers robot axes 1 to 6 (including wrist joints) and can accurately monitor whether the position of each axis falls within the preset safety range. Compared with the limitation that traditional mechanical switches only cover the main axes, it can take into account details such as wrist posture, optimize the occupation time of the working area, and shorten the production cycle.

Flexible Signal Configuration: It is equipped with 5 safety output channels and 1 safety input channel. The safety outputs can be flexibly configured, and each channel can feed back the position combination status of any axis. The safety input is used to synchronize the EPS unit with the robot controller, ensuring signal consistency and action coordination.

Independent Safety Control: Operating on a safety-grade computer independent of the robot's regular control system, it complies with multiple safety standards. Through mechanisms such as cyclic synchronization verification and software synchronization checks, it can monitor control system errors in real time to ensure reliable safety responses.

Replacement of Mechanical Switches: It eliminates mechanical limit switches and ground cables, and completes debugging through software configuration to achieve maintenance-free operation, which reduces mechanical wear and failures, and lowers long-term operating costs.

Technical Parameters

The model is 3HAC026271-001. It is compatible with the IRC5 controller and monitors 6 axes (axes 1 to 6). It is configured with 1 safety input channel and 5 safety output channels. It complies with safety standards including the Machinery Directive 98/37/EC, ISO 13849-1 and ISO 10218-1, and meets the safety level of PL d and Category 3 specified in ISO 13849-1. Its communication interface is compatible with that of the IRC5 controller and supports the interaction of safety signals. It meets industrial-grade standards, adapts to harsh factory environments and has anti-interference capability.

Application Scenarios

Automotive Manufacturing: In robot operations such as welding, painting and assembly, it monitors the movement range of robotic arms to prevent collisions with personnel and equipment, ensuring the safe and efficient operation of production lines.

Electronic Processing: In high-precision operation scenarios, it precisely controls the positions of robot wrists and end effectors to avoid damage to precision components while ensuring the safety of operators.

bIt is suitable for various robot workstations equipped with ABB IRC5 controllers, especially for scenarios where the working area needs to be adjusted frequently and the human-machine collaboration process needs to be optimized, improving the flexibility and safety of production lines.

3005319639

3005319639