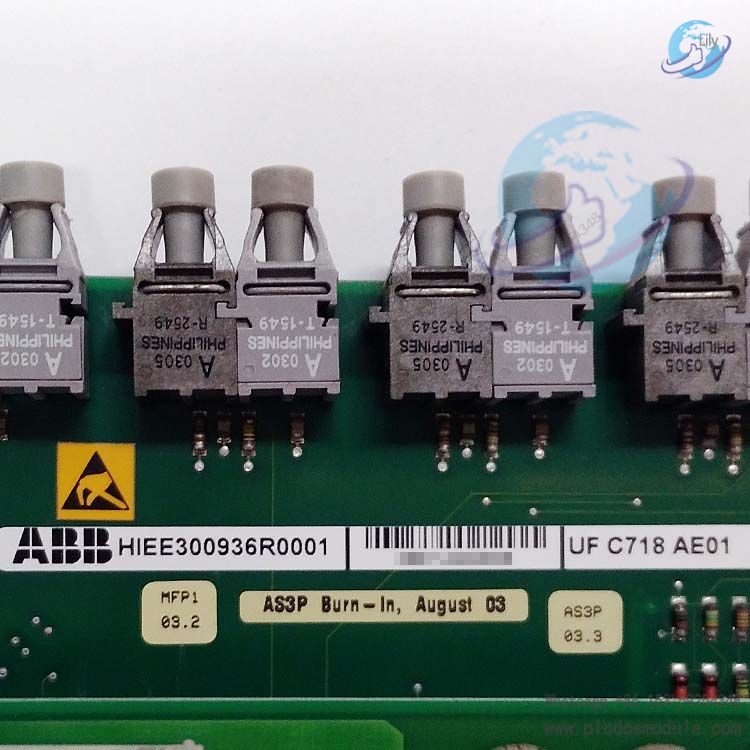

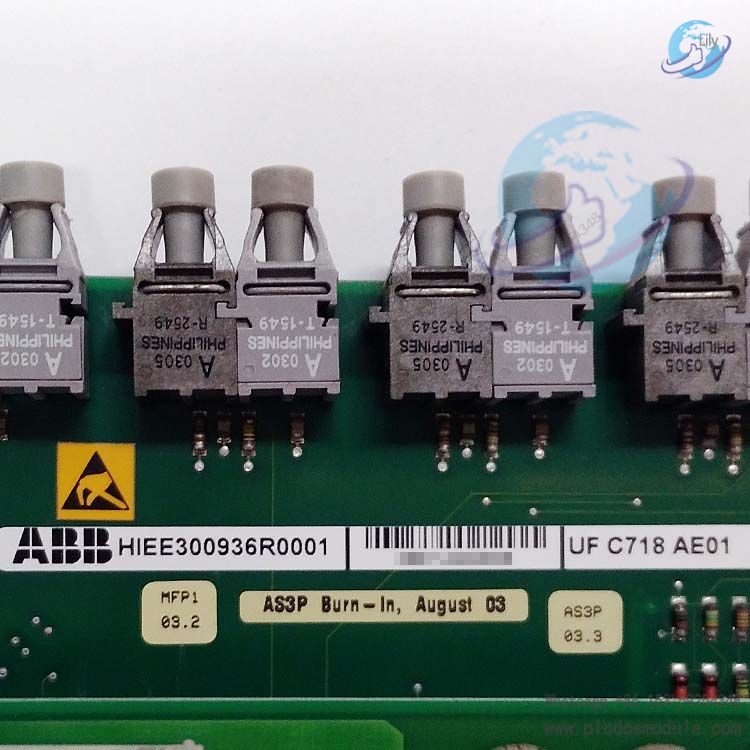

Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. ABB UFC718AE01 (Order Number: HIEE300936R0001) is a PROFIBUS DP‑V1 fieldbus communication interface module, specifically designed for ABB Freelance and AC 800F series controllers. Serving as a critical communication bridge, it does not directly process control logic but accurately transmits controller instructions and real-time feedback of on-site data. The module can be flexibly configured as either a master or slave mode, facilitating efficient distributed I/O expansion and cross-vendor system integration in industrial automation systems. Additionally, it boasts high reliability and user-friendly integration features, making it suitable for harsh industrial environments.

Technical Specifications

The compatible controllers include ABB Freelance and AC 800F series. The power supply is provided via the controller backplane. The operating temperature ranges from 0°C to +60°C. It complies with PROFIBUS standards, CE, and other industrial electromagnetic compatibility standards. The maximum number of slaves (in master mode) depends on the controller's performance and configuration, and typically a large number of slaves can be connected.

Structural Design and Reliability

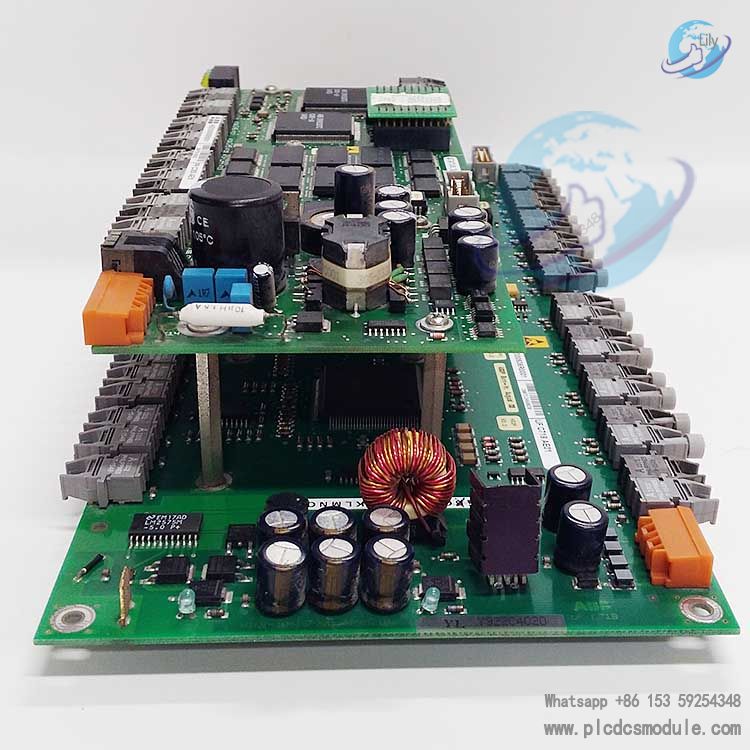

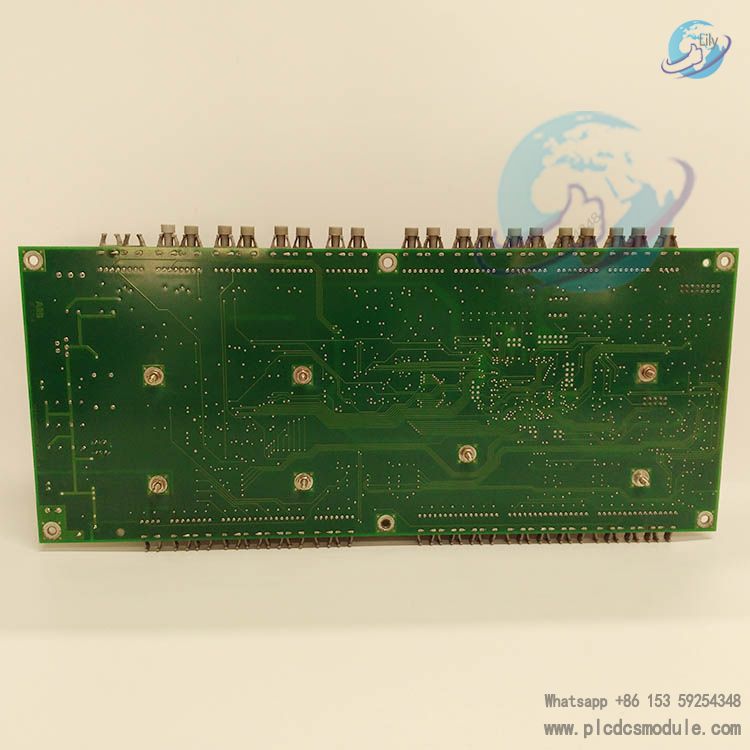

- Modular Design: Adopting a compact modular structure, it can be inserted into the controller rack or specific interface unit, enabling convenient installation, maintenance, and expansion. It can be flexibly configured according to application requirements.

- Industrial-Grade Protection: Designed in line with industrial standards, it features high anti-interference capability, allowing stable operation in harsh industrial environments. It ensures long-term trouble-free work and reduces the risk of system downtime.

- Redundancy and Protection: Redundant configuration is supported in some scenarios. Meanwhile, relying on designs such as electrical isolation, it possesses certain overcurrent and overvoltage resistance capabilities to protect the safety of the module and associated equipment.

Core Functions and Communication Capabilities

Protocol and Mode Support: Complies with the PROFIBUS DP protocol as specified in EN 50170 standard, supports DP‑V1 version, and is compatible with two operating modes: Master and Slave. In Master mode, it can manage distributed remote I/O stations; in Slave mode, it can integrate ABB controllers and their subordinate I/O systems into PROFIBUS DP networks controlled by third-party Masters.

Data Transmission Performance: The data transmission rate ranges from 9.6 kbit/s to 12 Mbit/s, supporting both automatic detection and manual setting. It can adapt to different communication distances and real-time requirements, ensuring efficient and stable data transmission.

Electrical Interface and Isolation: Equipped with an RS‑485 electrical interface, it connects to the PROFIBUS DP network via a 9-pin D‑sub connector. Electrical isolation is implemented between the bus interface and the control side, enhancing anti-interference capability and ensuring the accuracy of signal transmission.

System Integration Convenience: Provides standard GSD files to facilitate quick integration into third-party Master systems, simplifying the configuration process and reducing system integration time and costs.

Structural Design and Reliability

Modular Design: Adopting a compact modular structure, it can be inserted into controller racks or specific interface units, enabling convenient installation, maintenance, and expansion. It can be flexibly configured according to application requirements.

Industrial-Grade Protection: Designed in compliance with industrial standards, it features high anti-interference capability, allowing stable operation in harsh industrial environments. It ensures long-term trouble-free operation and reduces the risk of system downtime.

Redundancy and Protection: Redundant configuration is supported in certain scenarios. Meanwhile, relying on designs such as electrical isolation, it possesses a certain degree of overcurrent and overvoltage resistance, protecting the safety of the module and associated equipment.

Typical Application Scenarios

Distributed I/O Expansion: In Master mode, it connects to remote I/O stations (e.g., ET 200M), significantly expanding the physical I/O coverage of the controller and reducing on-site wiring costs. It is suitable for process industrial scenarios requiring distributed control, such as large-scale chemical, power, and water treatment industries.

Cross-Vendor System Integration: In Slave mode, it can integrate ABB control systems into third-party Master networks (e.g., Siemens, Rockwell), making it ideal for comprehensive automation projects with coexisting multi-vendor equipment, such as automobile manufacturing and metallurgical production lines.

Data Acquisition and Monitoring: It assists controllers in real-time acquisition of on-site equipment data, enabling remote monitoring, fault diagnosis, and predictive maintenance. This improves production efficiency and equipment management levels, and is applicable to fields such as building infrastructure, data centers, and renewable energy.

Key Points for Installation and Commissioning

During installation, insert the module into the designated slot of the corresponding controller rack to ensure good contact for backplane power supply, and wire the 9-pin D-sub connector in compliance with PROFIBUS DP specifications.

Complete configuration using standard GSD files, select the Master/Slave mode based on network requirements, set the transmission rate, and finish the communication parameter configuration and device mapping via the controller software.

In the commissioning phase, use the diagnostic tools built into the controller to check the communication link status and data transmission integrity, and promptly troubleshoot bus faults or configuration errors.

Customers who purchased this product also viewed these products:

ABB CI854AK01 3BSE030220R1 Communication Module

ABB PM863K01 3BSE088381R1 AC 800M CONTROLLERS

ABB PPD517A3011 3BHE051476R3011 Converter Controller

ABB CI868K01-eA 3BSE048845R2 Communication Interface module

3005319639

3005319639