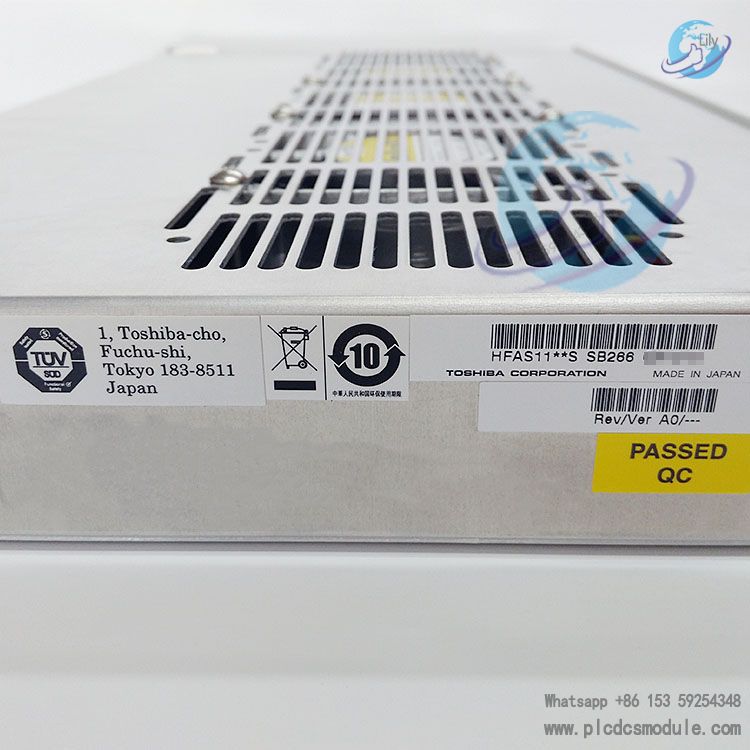

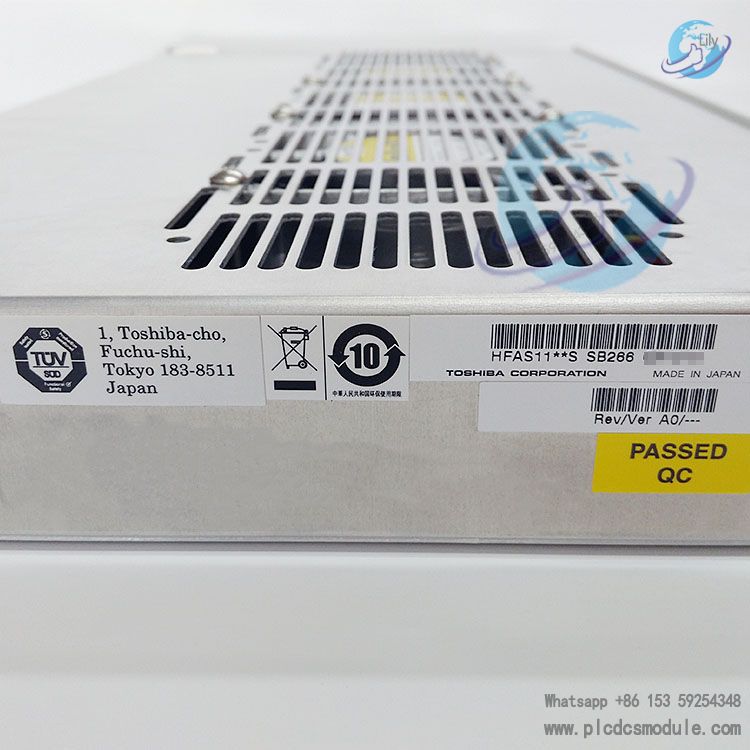

Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. The TOSHIBA HFAS11S is a high-performance servo drive launched by Toshiba for the industrial automation sector. Boasting flexible adaptability, stable operational performance and a rich array of functions, it precisely meets the requirements of various precision motion control scenarios and is compatible with the servo control needs of a wide range of industrial equipment. It delivers reliable drive and control solutions for fields such as automated production lines, machine tool processing and packaging machinery, helping to enhance equipment operational precision and production efficiency.

Technical Specifications

Power Supply Specification: Adaptable to single-phase or three-phase AC 200V - 480V power supplies, with 24VDC models also available. It is compatible with diverse industrial power supply environments and meets the power configuration requirements of most industrial equipment.

Output Performance: Equipped with 16 digital output channels, each with a maximum load current of 0.5A. It can drive various types of loads such as motors, relays and bulbs, meeting the control requirements of diversified actuators in industrial scenarios.

Output Type: Supports two output types – PNP type (positive logic) and NPN type (negative logic), which can be flexibly switched according to the peripheral control logic to improve compatibility with different control systems and peripherals.

Environmental Adaptability: With an IP20 protection grade, it can effectively prevent dust intrusion and ensure the stable operation of internal circuits; the operating temperature range is 0℃ - 55℃, adaptable to common temperature environments in industrial sites; the product weighs approximately 260 grams, featuring easy installation and low requirements for equipment installation space.

Structure & Installation: Adopts an integrated structural design and supports on-site installation, meeting the needs for rapid deployment and maintenance in industrial sites. The LD instruction processor is configured with a hard PLC to ensure high efficiency and stability of instruction execution.

Core Functional Features

High-Speed Response Control: Supports high-speed digital output, enabling rapid response to command signals from upper controllers (e.g., PLCs, motion control cards, etc.). It shortens the execution delay of control instructions, improves the dynamic response speed of equipment motion control, and ensures precision positioning and synchronous operation accuracy.

Flexible Programmable Configuration: Supports flexible parameter configuration and custom control logic. Users can adjust output modes, response parameters, etc., according to specific application scenarios to meet the control requirements of different equipment and enhance the product's versatility and adaptability.

Stable Operational Capability: Optimized circuit design and protective structure enable stable operation even in harsh industrial environments such as high temperature and humidity, reducing the interference of environmental factors on equipment operation and lowering the probability of fault shutdowns.

User-Friendly Maintenance Design: The integrated structure is matched with detachable control terminals, facilitating on-site wiring, debugging and maintenance, reducing the difficulty and time cost of equipment operation and maintenance, and improving the operation and maintenance efficiency of industrial sites.

Protection Mechanisms

Basic Electrical Protection: Equipped with overcurrent and overvoltage protection functions. When the output current or power supply voltage exceeds the rated range, the protection mechanism is triggered automatically to cut off the output or limit the current, preventing damage to the drive and external loads.

Environmental Protection: The IP20 protection rating effectively prevents dust from entering the interior of the device and avoids faults such as circuit short circuits; it also has a certain moisture-proof capacity to adapt to humid industrial environments.

Thermal Protection: Built-in thermal overload protection function. When the device operates at an excessively high temperature, the protection program is activated automatically to avoid component aging or damage caused by overheating and extend the product service life.

Typical Application Scenarios

This drive is widely used in various fields of industrial automation, such as the control of spindles and feed axes of machine tool processing equipment to ensure processing precision and efficiency; the control of conveying mechanisms and positioning devices in automated production lines to achieve precise connection between processes; the synchronous positioning and motion control of packaging machinery to improve packaging precision and speed; the control of conveying equipment and robotic arm joints in handling and logistics systems to ensure the stability and accuracy of material handling. In addition, it can also be applied to equipment requiring precision motion control such as textile machinery and robot systems, helping to improve the automation level and production efficiency of the equipment.

Customers who purchased this product also viewed these products:

Toshiba DPHC06-01 Digital Input PCB, TOSMAP Turbine Generator Control

TOSHIBA HC422B 7862 2N3B2895-C5 N-300 circuit board

Toshiba AICW01-G022 PCB, TOSMAP Turbine Generator

TOSHIBA HC422B 7862 2N3B2895-C5 N-300 circuit board

3005319639

3005319639