Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. The

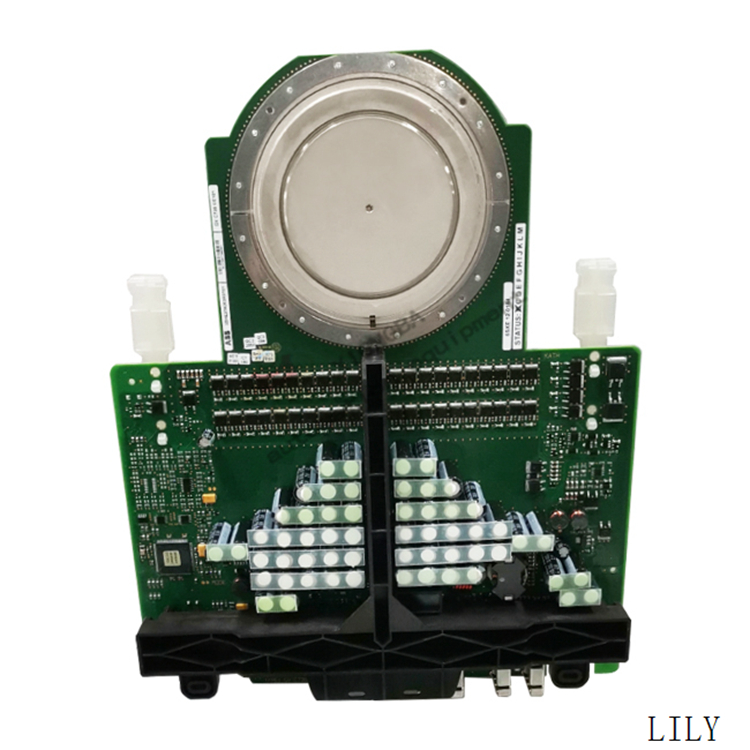

ABB/Bailey IMHSS03 Hydraulic Servo Module is a valve position control module specially designed for the INFI 90 system. As a core I/O component of the Symphony enterprise management and control system, it realizes manual or automatic control of hydraulic actuators by connecting to servo valves or I/H converters. Widely applied in the regulation of key valves for equipment such as steam turbines and gas turbines, it serves as a core component ensuring the precise speed control of turbines.

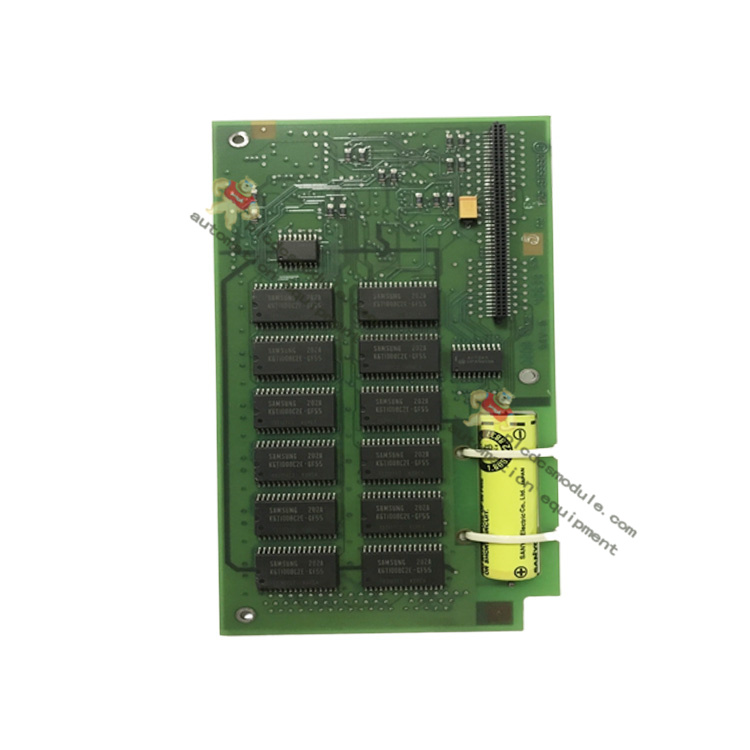

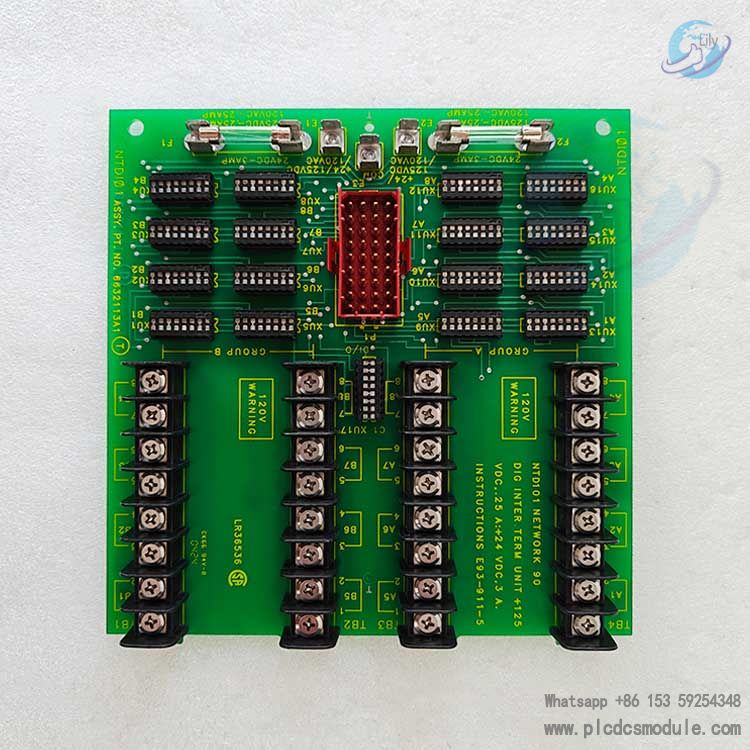

This module features a single printed circuit board design and occupies only one slot of the Module Mounting Unit (MMU). It needs to be connected to the terminal unit via cables, with the physical connection points for field wiring located on the terminal unit. Meanwhile, the configuration of the module and its I/O channels can be completed through jumpers and switches on the circuit board, as well as jumpers and pin-type shunts on the terminal unit, boasting the characteristics of a compact structure and flexible configuration.

related documents

IMHSS03 Data Sheet.pdf

IMHSS03 Data Sheet.pdf

ABB Bailey IMHSS03.pdf

ABB Bailey IMHSS03.pdf

Key Technical Parameters

Mounting method: Occupies 1 slot of the standard Module Mounting Unit (MMU);Operating temperature: 0°C~70°C (32°F~158°F);Relative humidity: 5%~95% (Temperature ≤55°C/131°F, non-condensing), 5%~45% (Temperature =70°C/158°F, non-condensing);Altitude range: Sea level to 3km (1.86 miles);Air quality requirement: Non-corrosive environment; avoid corrosive media such as acid, alkali and dust that may affect the circuit performance of the module;Certification standards: Complies with CE certification (EMC Directive 89/336/EEC, Low Voltage Directive 73/23/EEC), certified by the Canadian Standards Association (CSA) and Factory Mutual (FM); suitable for general (non-hazardous) locations. It also meets the spark-free environmental requirements for Class I, Division 2 (Groups A, B, C, D) and Class II, Division 2 (Groups F, G) (FM certification for IMHSS03 is pending approval).

Power Supply and Power Consumption Parameters

Operating voltage: +5VDC (±5%), ±15VDC (±5%), +24VDC (±10%, supplied by the terminal unit);Typical current: 576mA at +5VDC, 15mA at +15VDC, 12mA at -15VDC, 335mA at +24VDC;Typical power consumption: 2.88W at +5VDC, 0.23W at +15VDC, 0.18W at -15VDC, 8.04W at +24VDC. The low-power design reduces module heating and extends service life.

Input and Output Parameters

LVDT-related interfaces: Includes 4 analog inputs (2 LVDT secondary inputs, 2 secondary coils per channel) with an input impedance of 10kΩ (differential), common-mode voltage of ±7VDC and input signal of 24V PP; 2 LVDT primary excitation outputs with an operating frequency of 400Hz~15kHz, the excitation voltage is matched to the minimum impedance (e.g., 2.1V PP for 15.0Ω, 6.0V PP for 40.0Ω, etc.);Servo valve output current: Supports multi-range current output (±8mA~±64mA); the maximum coil impedance varies with current (750Ω~93Ω), compatible with servo valves of different specifications;Feedback and test outputs: 1 position panel meter output (4~20mA, maximum impedance 300Ω), 1 unscaled position feedback output (2mA, minimum impedance 5kΩ), 1 test mode output (1mA, minimum impedance 5kΩ), facilitating system debugging and status monitoring;Digital I/O: 3 optically isolated digital inputs (Raise, Lower, Trip Bias, minimum 18VDC/2.8mA, maximum 11VDC/10μA), 1 optically isolated open-collector digital output (Hard Manual, 2.4VDC/250mA, 24VDC/10μA), improving signal anti-interference capability and system safety.

Core Functions and Working Principle

The core function of the IMHSS03 module is to achieve precise position control of hydraulic actuators, and its working process is carried out around the cycle of command receiving - signal output - position feedback - closed-loop regulation. The controller needs to call function code 55 or 150 (Hydraulic Servo) to configure and access the module's I/O channels, and then send control signals to the servo valve or I/H converter to drive the action of the hydraulic actuator (e.g., adjusting the opening of steam turbine throttle valves and gas turbine fuel valves). Meanwhile, the Linear Variable Differential Transformer (LVDT) collects the position signal of the actuator in real time and transmits the feedback data to the module, forming a closed-loop control circuit to ensure the actuator position is highly consistent with the controller's command. This ultimately achieves precise regulation of turbine fuel or steam flow, thereby stabilizing the turbine speed.

In terms of system coordination, as an intelligent I/O module, the IMHSS03 is built-in with a microprocessor, memory and communication circuits, and needs to be used in conjunction with the IMFCS01 Frequency Counter Module in most application scenarios: the IMFCS01 collects the pulse signal from the magnetoelectric sensor on the turbine shaft, converts it into digital data and transmits it to the controller for calculating the actual turbine speed. The controller dynamically adjusts the output signal of the IMHSS03 by combining the speed data with the set value, further optimizing the turbine speed control accuracy and meeting the high reliability and high precision operation requirements of steam or gas turbine control systems

Typical Application Scenarios

With its high-precision control capability, the IMHSS03 module is widely used in turbine control across key industrial fields, with the main application scenarios as follows:

Steam turbine control: It adjusts the opening of throttle and control valves, stabilizes the rotational speed of steam turbines through the precise control of steam flow, and is suitable for energy production scenarios such as thermal power plants and combined heat and power generation;

Gas turbine control: It controls the opening of fuel valves, the angle of inlet guide vanes and nozzle angles to match the fuel demand of gas turbines under different operating conditions. Meanwhile, it optimizes combustion efficiency by regulating air intake volume, and is commonly applied in natural gas power generation, industrial drive and other fields;

Other industrial hydraulic control: In auxiliary equipment of metallurgy, aerospace and other fields, it can be used for the position control of hydraulically driven mechanisms (e.g., vibration control of continuous casting machine molds, drive of aircraft control surface simulation test benches), and improves the operational stability of equipment and product quality through micron-level control accuracy.

Customers who purchased this product are also browsing the following products:

ABB SPBRC410 Controller with Modbus TCP Interface

ABB DSAO130A 3BSE018294R1 Analog Input Board 16 Cannels module

ABB Bailey SPHSS03 Hydraulic Servo Module

ABB Bailey SPHSS13 Hydraulic Servo Module

3005319639

3005319639