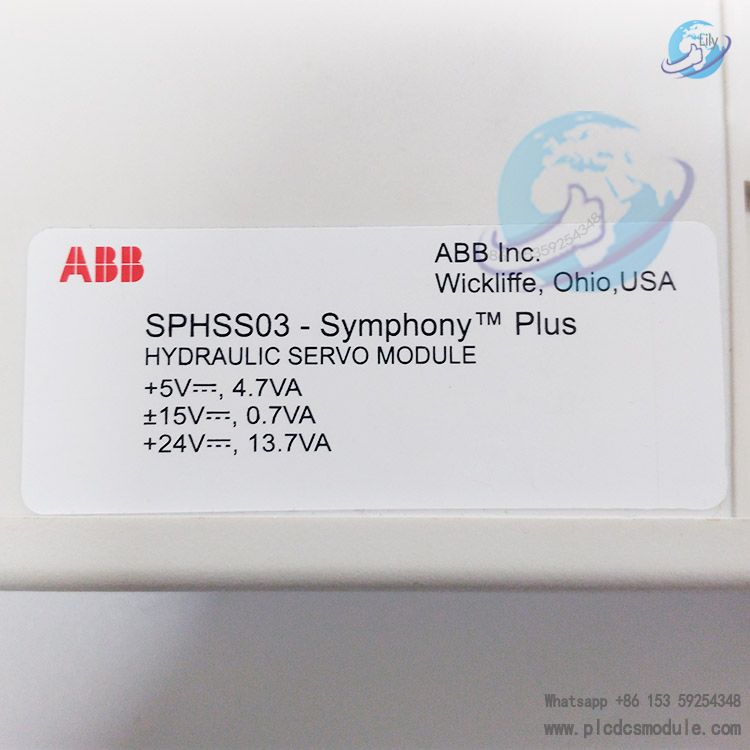

This module drives servo valves or electro-hydraulic converters (I/H converters) through interfaces to realize manual/automatic position adjustment of hydraulic actuators. Meanwhile, it receives position feedback signals from Linear Variable Differential Transformers (LVDTs) to form a closed-loop control system. This ensures the position accuracy and response speed of valves, making it a core component for speed regulation and control of key equipment in industries such as power and energy.

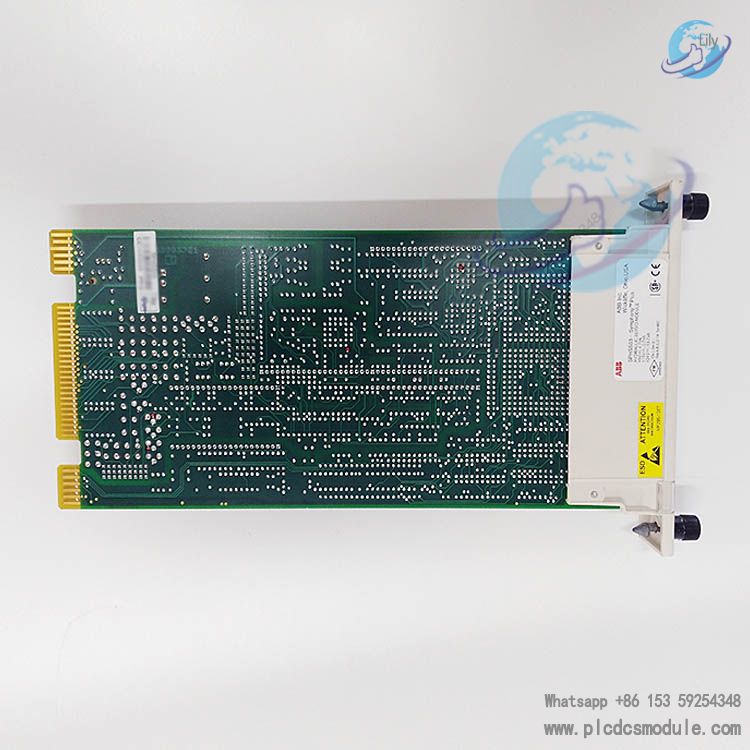

As a classic product for hydraulic servo control in the HR Series, the SPHSS03 features high responsiveness and strong stability. It can be directly integrated into the Symphony Plus Distributed Control System (DCS) and communicates seamlessly with HR Series controllers such as BRC410 and SPC810ev. Additionally, it supports AC/DC LVDT feedback adaptation, being compatible with different types of hydraulic actuators, which meets the on-site industrial requirements for high-precision and high-reliability control.

DATA SHEET

![]() ABB Bailey SPHSS03 Hydraulic Servo Module.pdf

ABB Bailey SPHSS03 Hydraulic Servo Module.pdf

Performance Specifications

1. Core Control Parameters

2. Power Supply and Power Consumption

3. Environmental and Physical Parameters

Advantages and Features

1. High Precision and High Responsiveness

2. High Reliability and Safety

3. Convenient Integration and Maintenance

Application Fields

With its high-precision hydraulic control capability, the ABB Bailey SPHSS03 occupies a core position in rotating machinery speed regulation and valve control scenarios, mainly applied in the following fields:

1. Power Industry

Steam Turbine Control: Drives the hydraulic actuators of steam turbine Governor Valves (GV) and Intercept Valves (IV). It accurately controls valve opening through LVDT feedback, adjusts steam flow, and realizes closed-loop control of steam turbine speed (3000 rpm/3600 rpm) and load.

Gas Turbine Control: Controls the hydraulic servo valves of gas turbine fuel valves and Inlet Guide Vanes (IGV), adjusts fuel supply and air intake volume, optimizes combustion efficiency, and ensures stable operation of the unit.

2. Petrochemical Industry

Compressor Control: Adapts to the hydraulic actuators of anti-surge valves and return valves of centrifugal compressors. It adjusts valve positions through the SPHSS03 to prevent compressor surge and ensure continuous compression process.

Large Pump and Valve Control: Controls the hydraulic system of the outlet control valve of high-pressure feed pumps in petrochemical plants, realizes precise adjustment of feed flow, and meets the requirements of reaction processes.

3. Energy and Power

Waste Heat Boiler Control: Adjusts the hydraulic actuator of the steam outlet valve of the waste heat boiler, matches the steam demand of the steam turbine generator set, and improves energy utilization efficiency.

Biomass Power Generation: Controls the hydraulic servo system of biomass fuel delivery valves, adapts to fluctuations in fuel characteristics, and stabilizes boiler load.

Q&A (Condensed)

Q: SPHSS03 "C" light off, unable to communicate with controller?

A:Check Expander Bus (e.g., NKTL01) for looseness; measure bus voltage (normal: +5 VDC).

Verify module address (0-63 for HR series) via S+ Engineering; reconfigure if conflicting.

Test module in a normal MMU slot: if "C" light turns on, replace original MMU.

Q: Valve controlled by SPHSS03 oscillates frequently?

A:Reduce proportional gain (e.g., 10→5) via S+ Engineering; optimize for no oscillation + fast response.

Check LVDT feedback with oscilloscope: fix shielding grounding or add filter if high-frequency noise exists.

Inspect hydraulic system: ensure oil viscosity (46# anti-wear oil) and no servo valve jamming.

Q: SPHSS03 no servo output current, valve unresponsive?

A:Confirm controller command (not 0); check logic (manual mode/trip signal).

Check "I" light: if on, read status register via S+ Engineering (Bit6=1 means overcurrent); test servo valve coil resistance (normal: 5-15 Ω) to rule out short circuit.

Customers who purchased this product are also browsing the following products:

ABB SPBRC410 Controller with Modbus TCP Interface

ABB DSAO130A 3BSE018294R1 Analog Input Board 16 Cannels module

Emerson Ovation 1C31122G01 digital output module

Motorola VME172PA652SE Module Control Board

3005319639

3005319639