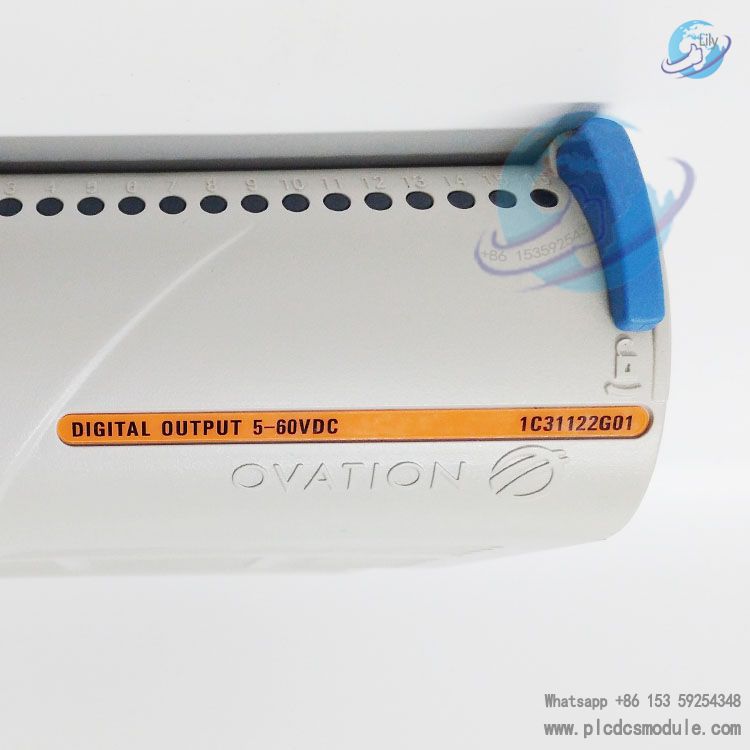

As a key component of the modular design of the Ovation system, the 1C31122G01 features "plug-and-play" functionality. It can be flexibly paired with designated Personality modules (e.g., models 1C31125G01/G02/G03) to achieve direct field control or linkage with relay panels. Meanwhile, it integrates comprehensive fault diagnosis, communication timeout protection, and fuse detection functions, ensuring high reliability and stability in industrial environments. Compliant with the CE certification standards, the module is suitable for harsh industrial conditions and serves as a crucial bridge for the Ovation system to realize signal interaction between the "control layer and field device layer".

DATA SHEET

Performance Parameters

1. Core Electrical Parameters

2. Environmental and Isolation Parameters

3. Power Consumption

Advantages and Features

1. High Reliability and Safety

Fuse Detection Function: Supports real-time monitoring of the auxiliary power fuse status. When the fuse blows or the auxiliary power voltage drops below the threshold, it triggers timely alarms via the "External Fault LED" and status register to prevent equipment damage.

Communication Timeout Protection: Allows configuration of communication timeout periods (62 ms - 16 s). After a timeout, it supports two modes: "Maintain Output State" or "Clear Output", adapting to safety requirements of different scenarios.

Wide Temperature Range and Anti-Interference Design: The operating temperature range covers 0-60°C, meeting the needs of high-temperature and high-humidity industrial on-site environments. Meanwhile, it has obtained CE certification and features strong electromagnetic interference resistance to ensure stable signal transmission.

2. Flexible Expandability

Compatibility with Multiple Personality Modules: Can be paired with 1C31125G01 (direct field interface), 1C31125G02 (local-powered relay panel interface), and 1C31125G03 (remote-powered relay panel interface), adapting to scenarios of direct control or high-power load expansion.

Relay Panel Linkage: Supports linkage with solid-state relay panels (AC/DC), G2R low-power electromechanical relay panels, and KU high-power electromechanical relay panels. This expands the capability to control high-voltage and high-current loads (e.g., 10 A @ 250 VAC loads).

3. Convenient Diagnosis and Maintenance

Visual LED Status Indication: Equipped with LEDs for P (Power), C (Communication), E (External Fault), I (Internal Fault), and 16 channel statuses, enabling intuitive fault localization.

Hot-Swappable Support: Supports "hot-swappable" replacement, allowing maintenance without shutting down the system, thus reducing system downtime.

Status Register Monitoring: Through the configuration/status register at address 13 (hexadecimal D), module configuration, fault status, and fuse information can be read remotely, facilitating remote operation and maintenance.

4. Modularization and Standardization

DIN Rail Mounting: Compatible with standard DIN rails, and shares the base unit with other I/O modules of the Ovation system, ensuring a unified installation layout.

Unified Bus Communication: Communicates with the controller via the Ovation serial I/O bus, and is compatible with the system's unified configuration tools (such as Ovation I/O Builder), reducing integration difficulty.

Application Fields

With its wide voltage output range, high current-carrying capacity, and strong anti-interference performance, the 1C31122G01 is widely used in industrial scenarios that have strict requirements for control accuracy and reliability. Its core application fields include:

1. Power Industry

Thermal Power Units: Controls the boiler water level regulating valves, fan start-stop relays, and outputs speed control signals for coal feeders.

Nuclear Power Plants: Realizes on-off control of auxiliary systems (such as cooling water pumps and ventilation systems) to meet the stability requirements of nuclear-grade equipment.

2. Petroleum and Chemical Industry

Oil Refining Equipment: Controls the reactor temperature regulating valves and outputs start-stop signals for feed pumps.

Natural Gas Processing: Drives the on-off operation of pipeline pressure regulating valves and emergency shut-off valves.

3. Metallurgy and Mining Industry

Iron and Steel Production: Controls the burners of blast furnace hot blast stoves and drives the solenoid valves of rolling mill hydraulic systems.

Non-Ferrous Metals: Outputs start-stop and speed regulation signals for mineral processing equipment (such as ball mills and flotation machines).

4. Water Treatment and Environmental Protection

Sewage Treatment: Controls the on-off operation of aeration fans and chemical dosing pumps.

Solid Waste Treatment: Drives the on-off operation of incinerator feed valves and the solenoid valves of flue gas purification systems.

5. Other Industrial Fields

Food and Beverage: Controls the start-stop of production line conveyors and the valves of filling equipment.

Pharmaceutical Industry: Regulates the air valves of air conditioning systems in sterile workshops and outputs start-stop signals for medicinal liquid mixing motors.

FAQ

Q: What is the output range of the 1C31122G01, and which loads can it drive?

A: The output voltage ranges from 0 to 60 VDC, with a maximum current of 500 mA per channel. The total current is limited by the fuse. It can drive medium-current loads such as relay coils, indicator lights, and small solenoid valves, and is suitable for controlling valves and pumps in power and chemical industry scenarios.

Q: How to troubleshoot module communication failures?

A: First, check if the communication cable is loose or broken; then confirm that the module's communication parameters (protocol, baud rate) match those of the controller; finally, use a tool to test the communication signal. If there is no signal, check the configuration; if the problem persists, replace the module for testing.

Q: What to do if the output is uncontrollable or incorrect?

A: First, verify the module's output mode, timeout, and other configurations; then check if the load is short-circuited or overloaded, and if the circuit is open; if multiple channels are abnormal, check the stability of the power supply. If the problem still exists, it is necessary to troubleshoot the module hardware.

Customers who purchased this product are also browsing the following products:

Emerson Ovation 5X00481G01 CPU Module

EMERSON Ovation 5X00119G01 Module

GE DS200DPCBG1AAA Direct Power Connect Board

Bently Nevada 1900/65A-01-00-01-00-00 Equipment Monitor

3005319639

3005319639

Customer Reviews

Customer Reviews (3)

Electric power industry users

★★★★★

October 15, 2024

We have utilized the 1C31122G01 module in the boiler control system of a 300 MW thermal power unit, primarily for controlling the solenoid valves of feedwater pumps and the relays of fans. Over the past 2-plus years of operation, the module has never experienced any misoperations or faults. In particular, its "maintain output on communication timeout" function prevented boiler water level fluctuations during a brief controller offline incident, ensuring the stable operation of the unit. Additionally, the LED status indicators are highly intuitive, allowing maintenance personnel to locate channel faults at a glance during operation and maintenance, which has significantly reduced downtime.

User in the Chemical Industry

★★★★☆

October 10, 2023

The temperature control valve of the reactor in the oil refining unit requires 48 VDC for driving, and the output range of the 1C31122G01 module is compatible. Its isolation design is reliable, and on-site motor interference has never affected the output; it also supports hot swapping. Last time, replacing the faulty module only took 5 minutes, which did not affect production. It is recommended that the terminal block be compatible with wires of larger wire gauge (currently supporting a maximum of 22 AWG).

Mike Johnson

★★★★★

January 23, 2025

We use the 1C31122G01 to control aeration fans and chemical dosing pumps. The module's fuse detection function helped us avoid an auxiliary power short-circuit accident — after the fuse blew, the module immediately issued an alarm, and we replaced the fuse in a timely manner, preventing equipment damage. In addition, the module integrates smoothly with the Ovation system; configuring parameters using I/O Builder takes only a few minutes, which is very user-friendly for operation and maintenance personnel.2.