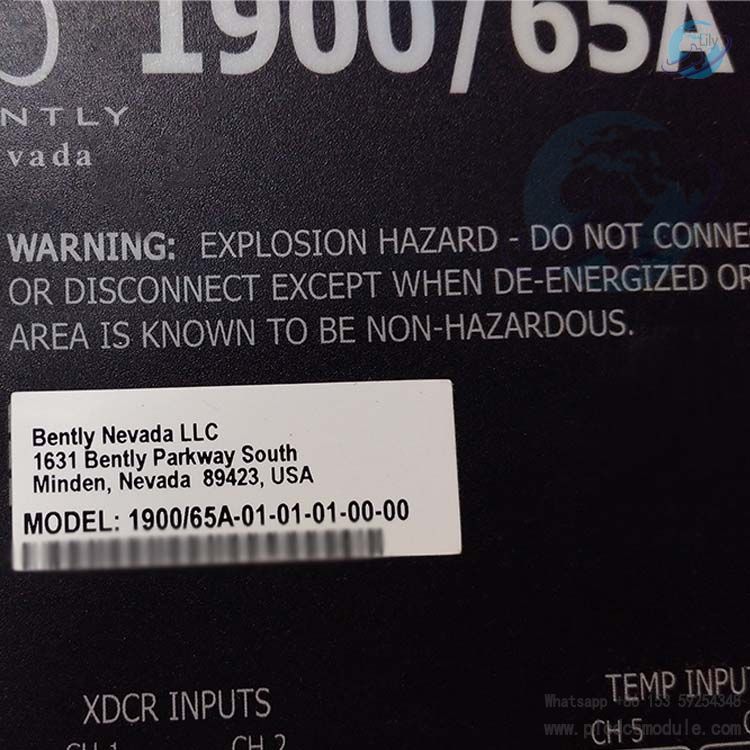

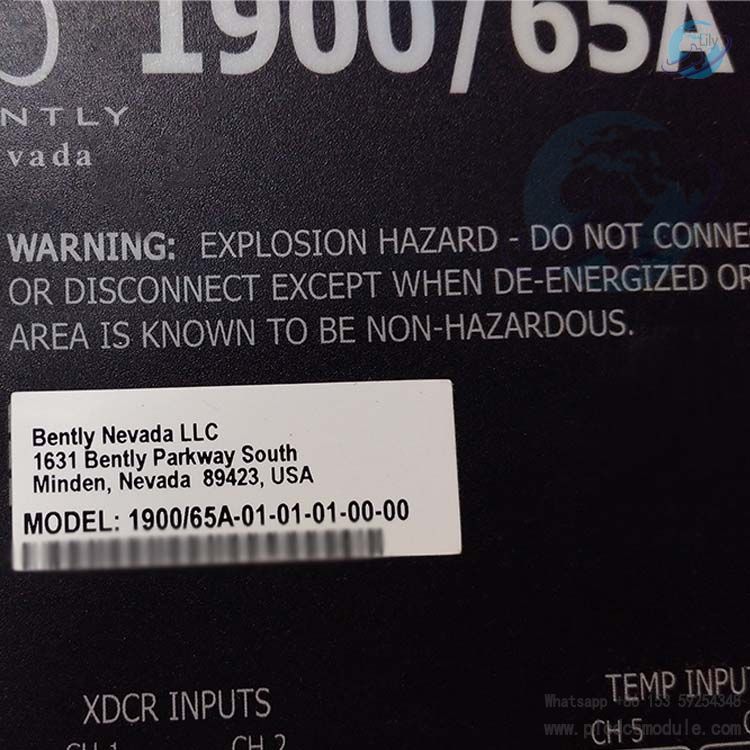

Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. (Based on the model coding rule: 1900/65A-AA-BB-CC-DD-EE, where AA=01, BB=00, CC=01, DD=00, EE=00)

- Product Name: 1900/65A General Purpose Equipment Monitor

- Brand: Bently Nevada (a brand under Baker Hughes)

Core Function: Provides continuous condition monitoring and protection for various equipment, supports multiple types of sensor inputs, data processing, and alarm control, suitable for equipment monitoring scenarios across multiple industries.

DATA SHEET

Bently Nevada 190065A.pdf

Bently Nevada 190065A.pdf

Configuration breakdown according to the coding rule:

- Power Supply Option (AA=01): 110-220 Vac (50-60 Hz), requires external power conversion (AC input is converted to DC suitable for the device via an external power supply).

- Display Option (BB=00): No built-in display; management is performed via configuration software or remote means.

- Mounting Option (CC=01): The specific mounting method corresponding to "01" is not explicitly stated in the documentation. Based on similar configurations, it is 推测 to be basic mounting (may support 35 mm DIN rail or wall mounting; details depend on accessories).

- Certification Option (DD=00): No specific national or industry certifications.

- Communication Option (EE=00): No built-in Modbus gateway; does not support Modbus protocol communication (can be added via the 1900/01 communication upgrade package if needed).

Sensor Inputs (4 channels):

Supports acceleration sensors (e.g., 330400, 330425), velocity sensors (e.g., 190501, 330500 series), proximity sensors (e.g., 3300 series), etc.

Configurable measurement types: acceleration, velocity, radial vibration, axial displacement, rotational speed, etc. Each channel supports up to 4 continuous calculation variables (e.g., vibration amplitude, gap voltage).

Temperature Inputs (4 channels, channels 5-8):

Supports E, J, K, T type thermocouples and 2/3-wire RTDs.

Measurement ranges: E type (-200~1000℃), J type (-210~1200℃), K type (-200~1370℃), T type (-200~400℃).

Filter Functions: 50 Hz low-pass analog filter; digital notch filter (attenuates 50/60 Hz interference with attenuation ≥100 dB).

Relay Outputs (6 channels):

Type: Single Pole Double Throw (SPDT), supports programmable logic control (based on the combination of "normal/alarm/danger" states of channels).

Contact specifications: Minimum switching current 12Vdc/100mA, maximum switching current 5A (AC/DC); supports latch/non-latch modes and normally open/normally closed configurations.

Other Outputs: 4 channels of 4-20 mA recorder outputs (proportional to full scale, accuracy ±2%); dedicated buffered outputs (raw signals without gain/scaling, with short-circuit protection).

- Accuracy: ±1% full scale for vibration variables; ±1~3℃ for temperature variables (depending on sensor type); ±0.5 RPM + 0.015% reading for rotational speed measurement.

- Response Time: Alarm delay is configurable (0.1-60 seconds for vibration/position inputs, 1-60 seconds for temperature/speed inputs, resolution 0.1 seconds).

- Environmental Adaptability:

Operating temperature: -20~70℃; storage temperature: -30~90℃.

Humidity: 95% non-condensing (both operating and storage).

- Configuration Tool: 1900 Configuration Software, supporting offline configuration, network device browsing, firmware upgrading, and status monitoring.

Core Functions: Channel parameter configuration (filtering, range, unit), relay logic programming, variable threshold setting (alarm/danger thresholds).

- Compatibility with Multiple Sensor Types: Supports accelerometers, velocity sensors, proximity sensors, thermocouples, RTDs, etc., covering measurement of parameters such as vibration, temperature, rotational speed, and displacement.

- Flexible Alarm Logic: Relays can combine multi-channel states via "AND/OR" logic (e.g., "channel alarm + equipment danger"), supporting 50 operands per relay.

- Reliability Design: Sensor power supply short-circuit protection, buffered output EMI protection, supports redundant power supply (requires external configuration).

- Compliance: Complies with RoHS directives; supports installation in hazardous areas (requires isolators/safety barriers, suitable for Zone 2/Class I Div 2 areas).

Suitable for condition monitoring of industrial equipment (e.g., pumps, motors, turbines), widely used in chemical, petroleum, power, manufacturing, and other fields. It can be integrated into DCS, SCADA systems or operate independently.

Optional accessories: DIN rail mounting brackets, waterproof enclosures (NEMA 4X/IP66), communication upgrade package (1900/01, supporting Modbus).

3005319639

3005319639