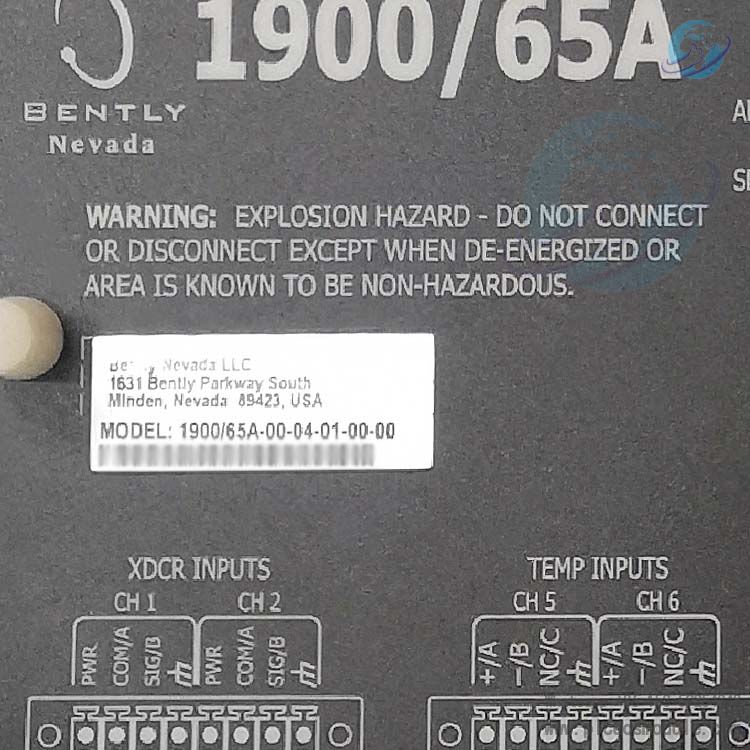

The Bently Nevada 1900/65A-00-04-01-00-00 General Purpose Equipment Monitor is a practical device specially designed for equipment monitoring and protection across multiple industries. It boasts significant cost advantages, capable of providing continuous and stable protection for general machinery and various processes.

In terms of input, it is equipped with four sensor input channels and four temperature input channels. The sensor inputs are highly flexible; through software configuration, they can be adapted to 2-wire and 3-wire accelerometers, velocity sensors, or proximity sensors, meeting the monitoring needs of different equipment. The temperature inputs support E, J, K, T-type thermocouples as well as 2-wire or 3-wire RTDs, comprehensively covering common temperature measurement scenarios.

The output functions are equally impressive, featuring six relay outputs. Users can flexibly program and control the opening and closing of relay contacts based on the "normal", "alarm", and "danger" states of channels via the 1900 Configuration Software. Additionally, there are four 4 - 20 mA recorder outputs, which can be set through software to output data of any variable from any channel, facilitating recording and analysis. It also provides dedicated buffered outputs to supply raw signals for each sensor input.

In terms of communication, an optional Modbus gateway is available, supporting Modbus communication via Ethernet or software-configurable RS 232/485 serial ports. It can directly transmit static variables, statuses, event lists, time, and date information to systems such as DCS and SCADA. Moreover, users can create configuration files using software on a laptop or PC to define monitor operations and Modbus gateway register mappings. The configuration information is permanently stored in non-volatile memory and can also be uploaded to a PC for modification. The device also supports an optional display/keypad, which is convenient for viewing channel information or making small-scale configuration changes. The display part can be installed at a maximum distance of 75 meters from the monitor module.

Technical Advantages of 1900/65A-00-04-01-00-00 General Purpose Equipment Monitor:

Flexible input adaptation capability: Supports 4 transducer inputs (configurable as acceleration, velocity, proximity sensors, etc.) and 4 temperature inputs (compatible with Type E, J, K, T thermocouples and 2/3-wire RTDs), covering multi-type parameter measurement to meet different equipment monitoring needs.

High precision and reliable measurement: Vibration variables feature an accuracy of ±1% of full scale, temperature measurement error as low as ±1°C (typical value), and speed measurement accuracy of ±0.5 RPM + 0.015% of reading, ensuring data accuracy.

Rich output and control functions: Equipped with 6 programmable relays (supporting logic combinations of 50 operands per relay), 4 channels of 4-20 mA recorder outputs, and dedicated buffered outputs, meeting the needs of alarm control and data recording.

Powerful configuration and compatibility: Realizes offline configuration and firmware upgrade via 1900 Configuration Software, supports Modbus Gateway expansion (compatible with DCS, SCADA systems, etc.), and can adapt to third-party device auto-discovery.

Environmental and safety adaptability: Operates in a temperature range of -20~70°C with 95% non-condensing humidity, featuring short-circuit protection for transducer power supply and EMI protection, and supports installation in hazardous areas (with isolators/barriers).

Efficient alarm and response mechanism: Alarm delay is configurable (0.1-60 seconds), supporting trigger via logic combination of multi-channel statuses, with rapid and accurate response to timely isolate abnormalities.

Customers who purchased this product are also browsing the following products:

BENTLY NEVADA 135489-01 3500/42M I/O Module

BENTLY NEVADA 106M1079-01 3500/15 Universal AC Power Supply

GE IS200TBCIS2CCD Mark VI Turbine Control PCB Module

GE Multilin MMII-PD-1-2-120 Mm2 Motor Manager

3005319639

3005319639