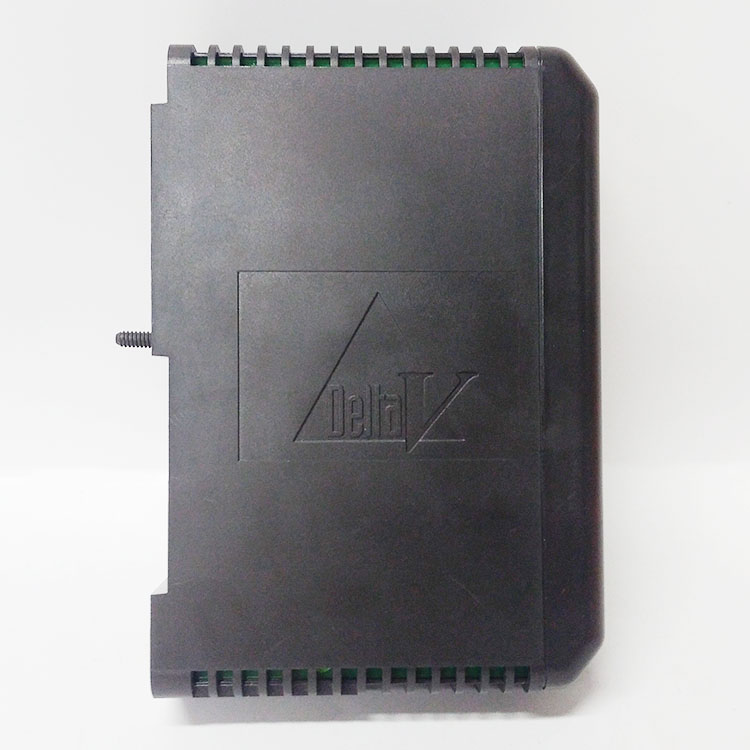

As a high-performance controller, it undertakes the communication and control tasks between field devices and other nodes in the control network. It not only is compatible with the control strategies and configurations of earlier DeltaV systems, but also achieves significant improvements in capacity, performance, and scalability.Meanwhile, it supports legacy system migration, providing users with a smooth transition solution to upgrade from existing equipment to advanced control architectures. The controller is widely applicable to automation control scenarios in various process industries.

related documents

![]() M-series DeltaV Controller.pdf

M-series DeltaV Controller.pdf

Technical Specifications

Power Supply & Hardware Specifications

Power Supply Requirement:Powered by the system power supply via a 2-wide power/controller carrier

Fuse Protection:3.0A non-replaceable fuse

Power Consumption:Typical value: 5.0W; Maximum value: 7.0W

Installation Method:Installed in the right slot of the power/controller carrier; supports 19-inch EIA rail mounting; a single DeltaV system can be expanded to 100 controller nodes

Dimensions:13.91 cm (H) × 16.06 cm (W) (5.48 in × 6.32 in)

User Memory:96 MB

Network Interfaces:Both the primary control network and redundant control network are equipped with 8-pin RJ-45 connectors

Operating Environment Parameters

Operating Temperature:-40°C to 60°C (-40°F to 140°F). Prolonged operation in the high-temperature range may shorten service life

Storage Temperature:-40°C to 85°C (-40°F to 185°F)

Relative Humidity:5% to 95% (non-condensing)

Air Contaminant Protection:Complies with ISA-S71.04-1985 Air Contaminant G3 Class conformal coating standard

Shock Resistance:Under normal operating conditions, it can withstand 10g half-sine wave shock for 11ms

Performance Metrics

Control Capacity:2 times that of the MD Plus controller; the number of supported Device Signal Tags (DST) is expanded from 50 to 1500

Configuration Memory:User-configurable memory is twice that of the MD Plus controller

Control Cycle:Control strategy execution speed up to 100ms per cycle

Communication Rate:Up to 4000 exception values can be transmitted per second

Redundancy Support:Supports 1:1 redundancy architecture to improve system availability

Software Compatibility

Minimum Software Version Requirement:DeltaV v10.3.0 or later. Hotfix is required for firmware v11.3.2 or earlier

Electronic Marshalling Support:DeltaV v14.3 or later supports assigning CHARMs via CHARM I/O Cards (CIOC), which must be used with DeltaV intelligent switches

Core Advantages

Flexible Adaptation & Seamless Upgrade

Dimension Compatibility: Matches MQ Controller dimensions for direct replacement (no configuration/hardware modification), adapting to late-stage project changes.

Capacity Expansion: Device Signal Tags (DST) scalable from 50 to 1500; software licenses upgrade flexibly with system scale, no hardware replacement needed.

Multi-language Support: Compatible with multi-control languages and user-defined structured text algorithms for diverse control strategies.

Ease of Use & Efficient O&M

Auto-configuration: Auto-addressing, auto-location and I/O detection enable plug-and-play (no manual setup) — unique address assigned on power-on, device characteristics recognized instantly after I/O insertion.

Visual Positioning: Ping command via UI triggers indicator flashing (excluding power light) for quick device location and troubleshooting.

Data Protection & Autonomous Restart: Online-modified parameters auto-saved for traceability; NVM RAM-stored control strategies enable power-failure auto-restart with zero manual intervention.

Powerful Connectivity & Integration

Electronic Marshalling: DeltaV v14.3+ supports easy I/O expansion via CHARM I/O Cards (CIOC) on Area Control Network.

HART Data Transparency: Transmits field device HART data to all control network workstations; supports AMS Device Manager for remote device management.

Integrated Diagnostics: Fully integrated with DeltaV Explorer/Control Studio; auto-identifies PROVOX I/O cards and monitors full diagnostic data to ensure I/O integrity.

Future-oriented Technology Reserve

Advanced Control: Runs neural network and model predictive control algorithms for complex process precision, boosting production efficiency and product quality.

System Compatibility: Works with DeltaV series I/O subsystems and traditional horizontal carriers; expands M-series I/O via 37-pin railbus for future scalability.

Long-term Support: Backed by Emerson’s global network, offering configuration migration and display transition services for smooth technology upgrades.

Application Fields

Process Industry Control Scenarios

Legacy System Migration Projects

Large-scale Control Unit Integration

Scenarios with High Availability Requirements

Supports 1:1 redundancy configuration and allows online upgrade of existing MD/MD Plus or MQ controllers. It is applicable to critical process links with high system availability requirements, such as chemical reactor control, power boiler regulation, and pharmaceutical batch production, ensuring that control tasks are not interrupted in the event of equipment failure.

Customers who purchased this product are also browsing the following products:

Emerson 1C31189G01 SPEED DETECTOR MODULE

Emerson 5X00357G04 CONTACT MODULE

Emerson Ovation 1C31169G02 Serial Link Controller Module

3005319639

3005319639