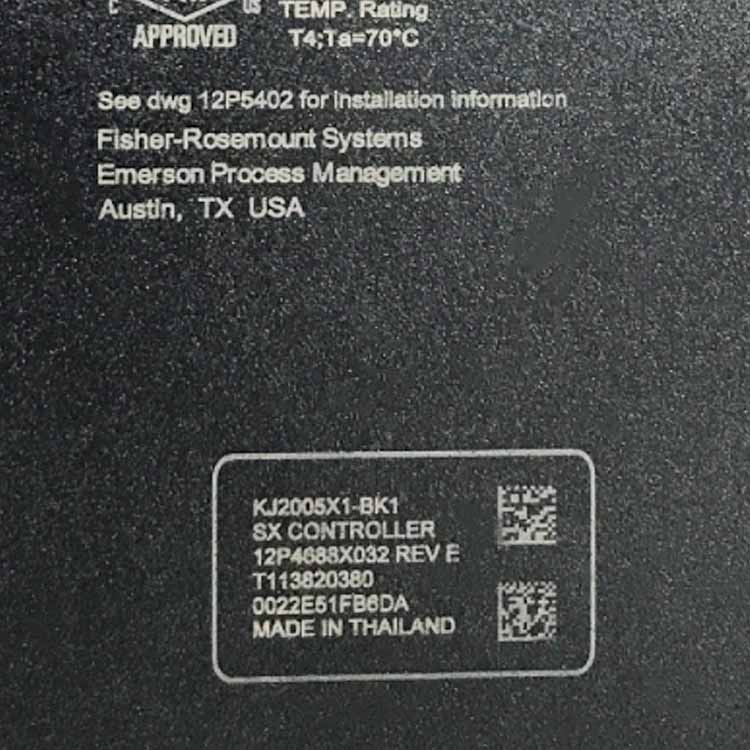

As one of the core models in the DeltaV S-series controller lineup, this product inherits the superior control performance and reliability of the DeltaV system. Equipped with a dedicated PROVOX I/O interface solution, it can directly connect to the factory’s installed PROVOX I/O devices without the need for re-wiring. This not only maximizes the protection of existing equipment investments, but also enables a smooth transition of the control system to the advanced DeltaV platform.It supports two connection modes: Control I/O and distributed MUX I/O, and is also equipped with a comprehensive redundancy design, full-featured engineering diagnostic functions, and deep compatibility with HART intelligent devices. It provides strong hardware support for the stable operation and efficient control of process industries.

related documents

![]() SE3007 S-Series DeltaV Controller.pdf

SE3007 S-Series DeltaV Controller.pdf

Technical Specifications

Basic Performance Parameters

Physical & Environmental Parameters

I/O Support Parameters

Supported PROVOX I/O Types

Unsupported I/O Types

CL6921 (Allen-Bradley interface option), CL6922/CL6923 (smart device interfaces), DM6004/DM6005 (virtual I/O couplers), DM6391 (2ac interface card), and other I/O cards not listed in the supported list.

Core Advantages

Investment Protection & Cost Savings

- Maximizes the investment value of existing PROVOX I/O devices, extends their service life, and avoids equipment obsolescence and waste caused by control system upgrades.

- Eliminates the need to rewire connections between on-site equipment and I/O modules, significantly reducing wiring costs and project renovation cycles.

High Reliability & Redundancy Assurance

- Supports controller redundancy (dual SX controller deployment), Control I/O connection redundancy, and Control I/O card redundancy (1:1, 1:N modes).

- Comprehensively covers key links from controllers to I/O interfaces, ensuring stable system operation even in the event of a single-point failure, and improving the stability and safety of industrial processes.

Seamless Integration & Ease of Use

- Fully integrates into the DeltaV system ecosystem, supporting standard engineering tools such as DeltaV Explorer and Control Studio.

- Enables automatic configuration, debugging, and channel assignment of PROVOX I/O, with operating logic consistent with DeltaV native I/O, reducing engineers' learning and operation costs.

- Diagnostic applications support fault information prompts for all PROVOX I/O, facilitating quick problem location.

Flexible Expansion & Compatibility

- Easily expands DeltaV S-series I/O modules through VerticalPLUS redundant backplane bus connection, realizing mixed deployment of PROVOX I/O and DeltaV native I/O.

- Supports connection to PROVOX IDIs, PLCs, and other serial devices (via DeltaV programmable serial cards), adapting to equipment interconnection needs in complex industrial sites.

Intelligent Data & Asset Management

- Equipped with HART protocol compatibility, capable of reading input/output data and device status information of HART smart devices connected to PROVOX.

- Achieves centralized management of on-site assets through the AMS system, providing data support for predictive maintenance and equipment performance optimization, and improving the intelligence level of factory operation and maintenance.

Application Fields

Process Industry Upgrade & Renovation Projects

- Suitable for factories with deployed PROVOX control systems (including UOC, IFC, Series 20, SR90, SRx controllers), such as petrochemical, chemical, power, water treatment, pharmaceutical and other industries.

- Ideal for scenarios that need to retain existing PROVOX I/O devices while upgrading to the DeltaV control system, eliminating the need to replace on-site I/O modules and rewire, which greatly reduces renovation difficulty and costs.

Industrial Scenarios with High Reliability Requirements

- Applicable to critical processes with extremely high requirements for control system redundancy and stability (e.g., continuous production chemical plants, power boiler control, core sewage treatment processes).

- Its design of controller redundancy, Control I/O connection redundancy, and I/O card redundancy (1:1 and 1:N modes) can effectively avoid system downtime caused by single-point failures and ensure production continuity.

Intelligent Device Integration & Asset Management Scenarios

- Supports data reading and transmission of HART protocol intelligent field devices, and can upload HART information to DeltaV application stations and Asset Management Solutions (AMS) asset management systems.

- Suitable for scenarios that require remote monitoring, diagnosis, and full-lifecycle management of on-site devices, improving equipment operation and maintenance efficiency.

Mixed Control Scenarios with Multiple I/O Types

- Compatible with multiple types of PROVOX I/O signals such as analog, discrete, pulse, thermocouple, and RTD.

- Can meet the centralized control needs of multiple parameters (temperature, pressure, flow, liquid level, switch status, etc.) in complex industrial processes, and is applicable to the automatic control of mixed-process production equipment.

Customers who purchased this product are also browsing the following products:

Emerson VE3006 KJ2003X1-BB1 12P3439X012 Md Plus Controller

EMERSON VE3007 KJ2005X1-BA1 12P4375X012 MX Controller

Emerson 1C31219G01 Ovation Relay Output Module

Emerson 1C31125G01 Digital Output Module

3005319639

3005319639