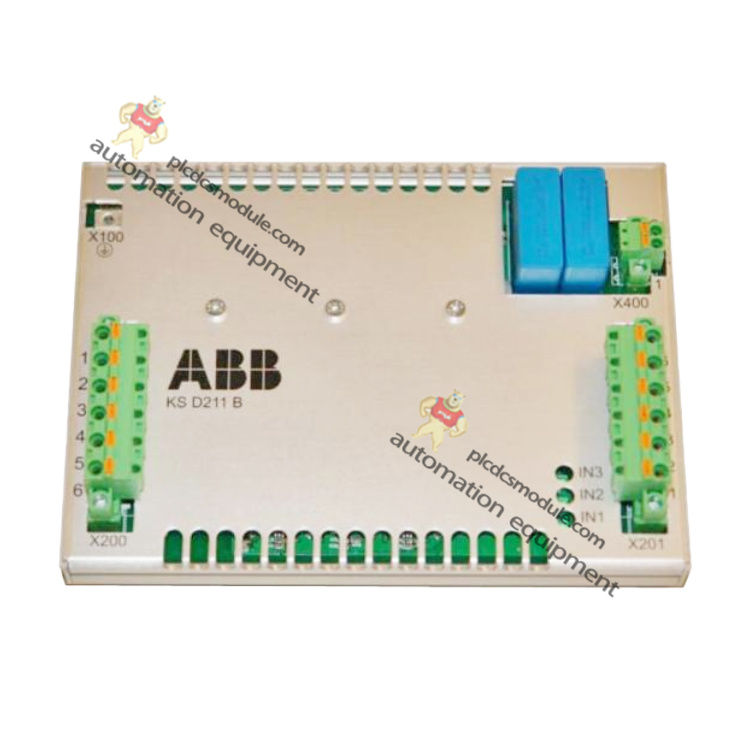

Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. ABB LT8978b V1 (HIEE320639R0001) is a high-performance PROFIBUS DP slave control board belonging to the HIEE3206 series, designed for the industrial automation field and integrated with pulse amplification functionality. It is primarily used to build a communication bridge between the PROFIBUS DP fieldbus, controllers and various industrial on-site devices, enabling core functions such as data acquisition, signal processing, control command transmission and device status monitoring. Adaptable to a variety of industrial scenarios including discrete control and process control, it can be seamlessly integrated into ABB automation systems and a wide range of third-party industrial control architectures, providing reliable communication support for the coordination and efficient operation of industrial on-site equipment. Its modular design ensures easy installation and efficient maintenance, along with adaptability to harsh industrial environments. Equipped with a comprehensive set of diagnostic and protection mechanisms, it can effectively reduce the risk of system downtime and improve the overall operational stability.

Core Functions

PROFIBUS DP Communication Adaptation: Supports the PROFIBUS DP V1 protocol with flexible node address configuration and a transmission rate range of 9.6 kbps - 12 Mbps. It enables stable data interaction and command delivery between controllers and field devices such as sensors and actuators, ensuring the real-time performance and determinacy of industrial control networks.

Pulse Amplification Function: Built-in pulse amplification circuit can accurately amplify and shape the input control pulse signals, and output pulse signals meeting the driving requirements of industrial equipment. It is adapted to the pulse control needs of servo drives, frequency converters and other devices, improving control precision.

Data Acquisition and Processing: Equipped with an advanced microprocessing unit, it can quickly collect digital signals from field devices and perform signal conditioning, filtering, logical operation and other processing, ensuring data accuracy and validity to provide a reliable basis for system control decision-making.

Fault Diagnosis and Protection: Integrated with a comprehensive built-in diagnostic function, it can real-time monitor the module's communication status, power supply status, signal transmission status, etc. When a fault occurs, it triggers an alarm and feeds back fault information in a timely manner for quick fault location and troubleshooting. It also features protection characteristics such as electrical isolation, overvoltage and overcurrent protection, which reduce damage to the module caused by industrial site interference and abnormal working conditions and extend its service life.

Flexible Configuration and Compatibility: The addresses and access modes of control and status registers can be configured via the CSR address space/access selection switches (S7, S4, S3), adapting to different VMEbus address mapping requirements and being compatible with a variety of industrial control devices to meet the diversified system integration needs.

Technical Parameters

Communication Parameters: The communication protocol is PROFIBUS DP V1 with a transmission rate of 9.6 kbps - 12 Mbps, supporting automatic node address configuration. The communication interface adopts an electrical isolation design with an isolation voltage of up to 180 VDC and strong anti-interference capability, ensuring stable data transmission.

Power Supply Parameters: The input voltage is compatible with the industrial standard of 24 VDC and features wide adaptability to voltage fluctuations, enabling stable operation within a ±10% range. The module has low power consumption of approximately 5 W during operation, reducing system energy consumption.

Pulse Amplification Parameters: The input pulse signal voltage range is 5-24 VDC, the output pulse signal voltage amplitude can reach 24 VDC, and the maximum output current is 2 A. The pulse frequency response range is 0-50 kHz, which is compatible with the driving requirements of various pulse control devices.

Mechanical and Environmental Parameters: The dimensions comply with industrial standard board specifications for easy installation in standard control cabinets. The operating temperature range is -25°C to +70°C, the storage temperature range is -40°C to +85°C, and the relative humidity is 5% - 95% (non-condensing). It has an IP20 protection rating, capable of withstanding common harsh industrial site conditions such as dust and vibration. With a weight of approximately 1 kg, it features a robust structure suitable for long-term continuous operation.

Interface Configuration: Equipped with a PROFIBUS DP communication interface, digital input/output interfaces, a power supply interface and a debugging interface. Among them, the digital input channels support dry/wet contact input, the digital output channels can directly drive small loads, and the debugging interface facilitates module parameter configuration and fault troubleshooting.

Application Scenarios

The LT8978b V1 (HIEE320639R0001) control board is widely used in fields such as manufacturing production lines, power systems, pump station control and valve control. It can realize remote control and status monitoring of equipment including motors, pumps and valves, and plays a key role in the distributed control systems of industries such as automobile manufacturing, chemical engineering and energy, helping industrial automation systems improve control precision, operational efficiency and reliability.

3005319639

3005319639